Accelerating your design and innovation, scale custom manufacturing

CNC machining, plastic molding and tooling supplier

For complete application of industrial, medical, kitchen & bathroom and electronics industry, looking to scale their business by out sourcing design & manufacturing

Rapid Prototyping

Tooling Sun offers an accelerated prototyping method that drastically reduces R&D time. What used to take months can now be done in weeks, providing a competitive edge effortlessly. our rapid prototyping ensures safer and faster product development, allowing quicker exploration of ideas.

Injection Molding

Our extensive manufacturing employs injection machines ranging from 60 to 1300 tons, catering to various part sizes, complexities, and volumes.Meeting stringent criteria and FDA standards, we fulfill your plastic prototype needs swiftly, providing on-demand, affordable, and high-quality molded parts within days.

CNC Machining

Our factory boasts cutting-edge CNC machining capabilities, enabling us to craft intricate designs and deliver precise custom parts with unparalleled accuracy. Utilizing advanced software and top-tier machinery, our skilled team transforms your concepts into reality, offering limitless customization options.

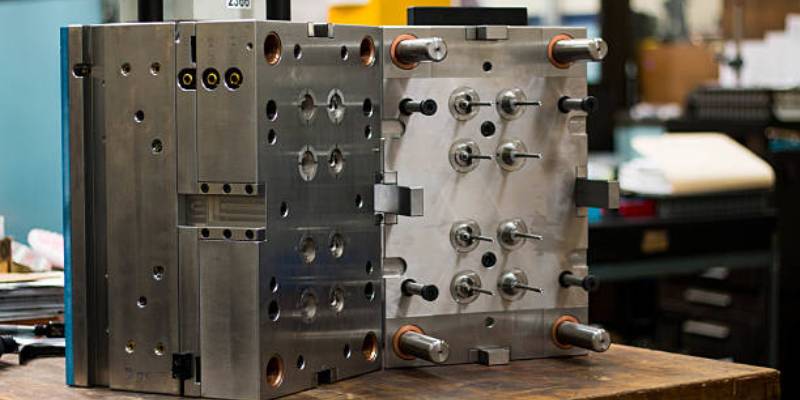

Tooling & Mold Manufacturing

With decades of expertise in tooling design, we specialize in various areas such as plastic injection molding, LSR injection molding, plastic and LSR over-molding, silicone compression molding, and metal stamping die. we offer high accuracy, repeatability, fast turnaround, and low investment in tooling or preparation costs.

Why Tooling Sun

Large Parts

Low Volumes

Low Tooling Cost

Design Freedom

Complex Geometry

Quality Assurance Manufacturing

Tooling Sun Company Profile

Tooling Sun engaged in engineering service and technical manufacturing, such as rapid prototyping, mold & tooling manufacturing, plastic & LSR injection molding, and CNC machining.

we own an industrial area of over 5,000 square meters. passed the ISO9001& IATF16949. The CNC machining workshop has over 20 machines, the accuracy the accuracy is ±0.001mm. the production workshop provide strong support and guarantee for the manufacture and research of complex and high-precision products and molds. We have fully possessed the advantages of mature precision injection molding, liquid silicone and 2K process manufacturing capabilities.

Our R&D team excels in ultra-precision silicone, plastic and LSR products, with innovations in cold runner systems, nozzle and valve opening, heating and insulation technologies, material selection and precision machining.

World Class Capabilities

Comprehensive Tooling & mold, Injection Molding Services & More

| INJECTION MOLDING SERVICES | MATERIALS |

| Molds making | Engineering Plastics: PA, PC, PPO/PPE, PEEK |

| Export Molds | Thermoplastics: PE, PP, PVC, PS, PC, Acrylic |

| Insert Molding | Nylon, Glass-filled Nylon, ABS, LSR, Low-Density Polyethylene (LDPE) |

| Overmolding | Fiber-Reinforced Plastic |

| Compression Molding | High-Impact Polystyrene |

| Mold Manufacturing | Acetal/Polyoxymethylene (POM) |

| Prototype Molds | Many Others |

Tooling Sun Services

How to Work With Us

Non-Disclosure Agreement

Successful partnerships thrive on trust. We highly prioritize confidentiality and safeguard your data and project specifics. Upon signing the NDA, we delve into your project and business objectives, working closely with you to ensure a deep understanding.

Request For Quote

The RFQ process showcases our competitive edge and collective capabilities. It grants us the chance to review your data thoroughly, ensuring we have all necessary details to craft a comprehensive proposal. We accept the file types: ProE (prt), IGES (igs), STEP (stp)

Parasolid (x_t), Your can send us your samples, too.

Manufacturing Agreement

The Manufacturing Agreement (MA) guarantees clear identification and documentation of legal, commercial, and service level expectations for both parties. Early clarification eliminates ambiguity, ensuring timely achievement of project milestones and commercial success.

Frequently Asked Questions

Answering Questions from tooling manufacturing to injection molding