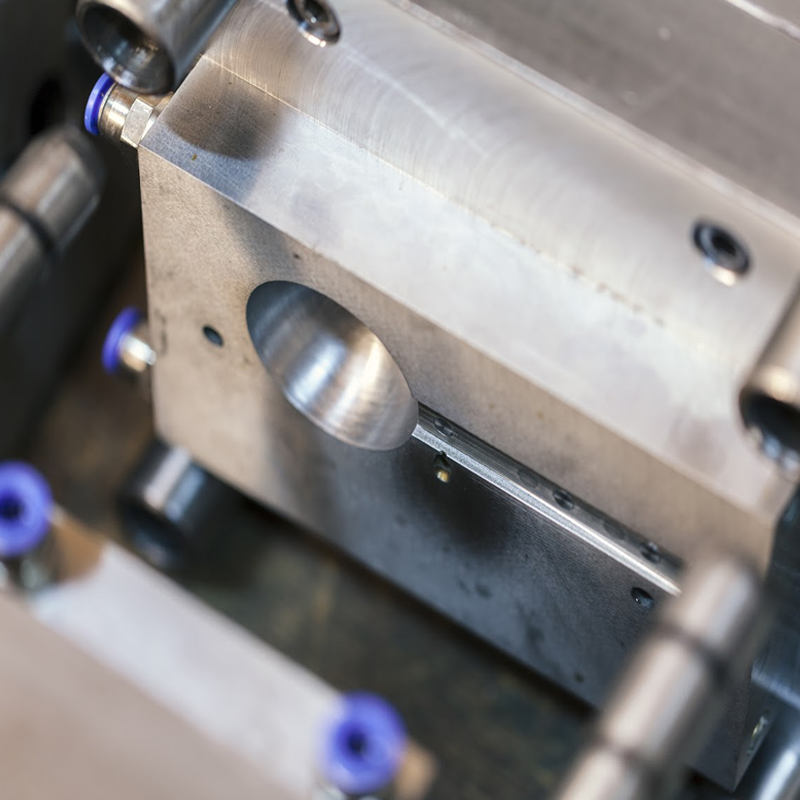

When it comes to mold making and mold casting, selecting the right materials is paramount to achieving optimal performance and longevity. The choice of material is heavily influenced by the specific service conditions and the intended use of the mold. Mold materials can be classified into several categories, including cold work, hot work, plastic mold, and specialized mold materials. Each of these categories is further subdivided based on their unique properties and applications.

Cold Work Mold Materials

Cold work mold materials are integral to many industrial applications due to their strength, hardness, and wear resistance. These materials are often used in high-precision molds that require high performance under normal processing conditions. In recent years, the demand for high-alloy steels has been on the rise, while the use of carbon tool steel has decreased.

Key Characteristics:

- High hardness and wear resistance

- Heat-treated to improve mechanical properties

- Often used in simple, small-batch molds and for prototypes

Common Types of Cold Work Mold Steel and Grades:

| Material Type | Example Grades |

| Carbon Tool Steel | T7, T8, T10 |

| Oil-Quenching Cold Work Mold Steel | 9Mn2V, CrWMn, 9CrWMn, 9SiCr, Cr2 |

| Air-Quenching Cold Work Mold Steel | Cr5Mo1V, Cr6WV, 8Cr2MnWMoVS, Cr4W2MoV |

| High Carbon High Chromium Cold Work Steel | Cr12MoV, Cr12, Cr12Mo1V1 |

| Matrix Steel & Low Carbon High-Speed Steel | 6W6Mo5Cr4V, 6Cr4W3Mo2VNb, 7W7Cr4MoV |

| Hard Alloy | YG6, YG8N, YG8C, YG11C, YG15, YG25 |

| Steel-Bonded Hard Alloy | GT35, TLMW50 |

Applications:

- Low-Alloy Cold Work Steel(e.g., 9CrWMn): Ideal for prototype molds and low-impact, small-batch production.

- Cr12 Type High Carbon Steel: A versatile choice for most molds with a focus on strength and wear resistance.

- W6Mo5Cr4V2 High-Speed Steel: Known for its high quenching permeability and excellent toughness, often used for high-performance molds.

Hot Work Mold Materials

Hot work mold materials are designed to withstand extreme conditions of elevated temperatures and complex cooling cycles. These molds are subjected to thermal stresses that require materials with exceptional thermal strength and resistance to cracking. While the range of materials is not as extensive as cold work steels, several grades are widely used for hot work applications.

Key Characteristics:

- Excellent thermal strength and crack resistance

- Ability to withstand rapid temperature fluctuations and high heat

- Designed to handle hot metal processes

Common Types of Hot Work Mold Steel and Grades:

| Material Type | Example Grades |

| Medium Carbon Tempered Steel | 45, 40Cr, 42CrMo, 40CrNiMo |

| Low-Alloy Tempered Mold Steel | 5CrMnMo, 5CrNiMo |

| Medium Chromium Hot Work Steel | H10, H11, H12, H13, H14, H19 |

| High Chromium Hot Work Steel | H23, H25 |

| Tungsten-Based Hot Work Steel | H21, H22, H26 |

Applications:

- Chromium Hot Work Steels (e.g., H13): Widely used for dies and molds that must endure high temperatures and thermal cycling, commonly in the automotive and aerospace industries.

- Tungsten Hot Work Steels (e.g., H21, H22): Excellent for high-temperature applications such as die-casting molds in the steel industry.

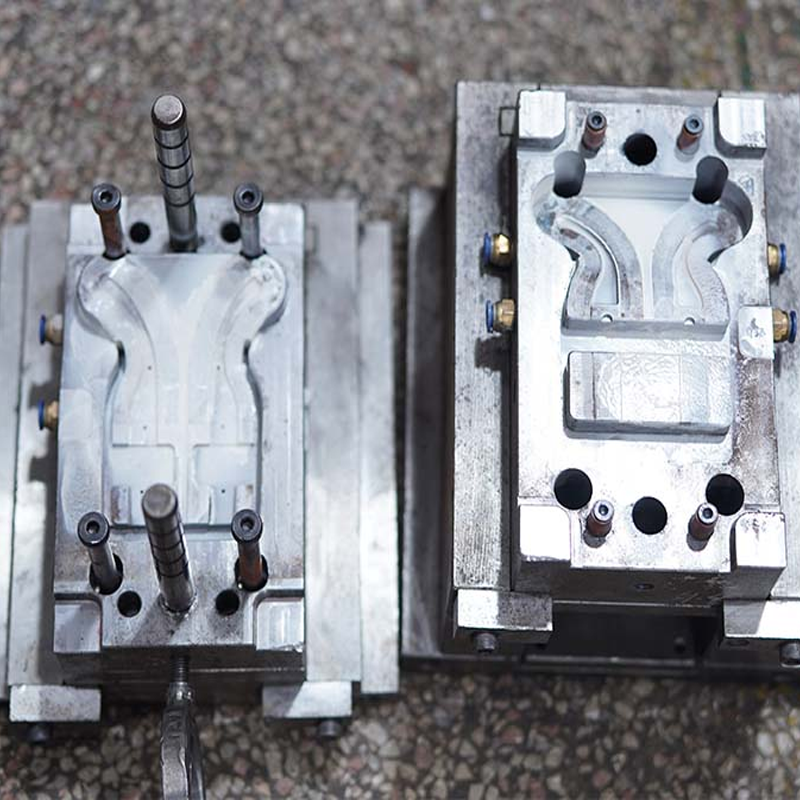

Plastic Mold Steel Materials

Plastic molds require materials that can withstand varying degrees of stress, precision, and durability, depending on the application. The steel chosen for plastic molds must balance characteristics such as corrosion resistance, wear resistance, and ease of processing.

Key Factors Affecting Selection:

- Object Being Processed: Plastic products vary greatly in complexity and size.

- Manufacturing Method: Injection molding, blow molding, and extrusion each have unique requirements.

- Durability and Precision Needs: Molds must meet the required lifespan and dimensional tolerance.

Common Types of Plastic Mold Steel and Grades:

| Material Type | Example Grades |

| Carbon Steel | 45, 50, 55, T8, T10 |

| Carburizing Type Plastic Mold Steel | 20Cr, 20CrMnTi, 20Cr2Ni4, 12Cr2Ni4 |

| Pre-Hardened Plastic Mold Steel | 3Cr2Mo, 3Cr2NiMnMo, 5CrMnMo, 8Cr2MnWMoVS |

| Corrosion-Resistant Plastic Mold Steel | 25CrNi3MoAl, 06Ni6CrMoVTiAl, 18Ni |

| Overall Hardening Type Steel | CrWMn, 9CrWMn, 9Mn2V, Cr12MoV |

Other Specialized Mold Materials

In addition to the primary categories mentioned above, there are several specialized materials used for specific applications. These include non-ferrous alloy materials, glass mold steels, and cutting-edge new mold materials.

Non-Ferrous Alloy Mold Materials

With the rise of small-batch and customized production, non-ferrous alloys such as copper, aluminum, and zinc alloys are increasingly used in mold manufacturing. These materials offer unique advantages like low melting points, excellent machinability, and recyclability.

| Material | Characteristics | Applications |

| Copper Alloys | Good anti-adhesion and thermal conductivity | Stainless steel forming, injection molds |

| Aluminum Alloys | Easy to machine, excellent corrosion resistance | Guide plates, prototype molds, plastic molding |

| Zinc Alloys | Low melting point, excellent machinability | Prototype molds, bending molds, aluminum extrusion molds |

Glass Mold Materials

Glass molds must withstand extreme temperatures and oxidation while maintaining high precision. Heat-resistant alloys and alloy cast irons are commonly used to handle these challenging conditions.

Specialized New Mold Materials

Ongoing research has led to the development of innovative mold materials, such as non-magnetic CrMnN steels for electronic products and high-temperature resistant alloys for glass molding.

Partner with Toolingsun for Precision Mold Materials

At Toolingsun, we understand the critical importance of selecting the right mold materials for your production needs. Our expertise spans across a wide range of mold materials, including cold work, hot work, plastic mold steels, and specialized alloys. We are dedicated to providing our clients with tailored solutions that ensure the highest performance, durability, and cost-effectiveness in every project.

Have Questions?

Whether you need advice on selecting the best material for your mold or assistance with custom mold manufacturing, our team at Toolingsun is here to help. Reach out to us today to discuss your project, and let’s work together to find the perfect mold solution for your needs!