Medical device manufacturing requires precision, efficiency, and advanced molding techniques to meet stringent quality standards. Different mold types, processes, and runner systems are utilized to produce medical components, ranging from syringes and tubing to trays and connectors. Each method offers distinct benefits depending on the application, design, and material requirements.

At Toolingsun, we specialize in providing customized mold solutions to support the evolving needs of the medical industry. Below, we’ll explore the key molding processes, types of injection molding, and mold configurations that are essential for medical device production.

Primary Molding Processes for Medical Devices

-

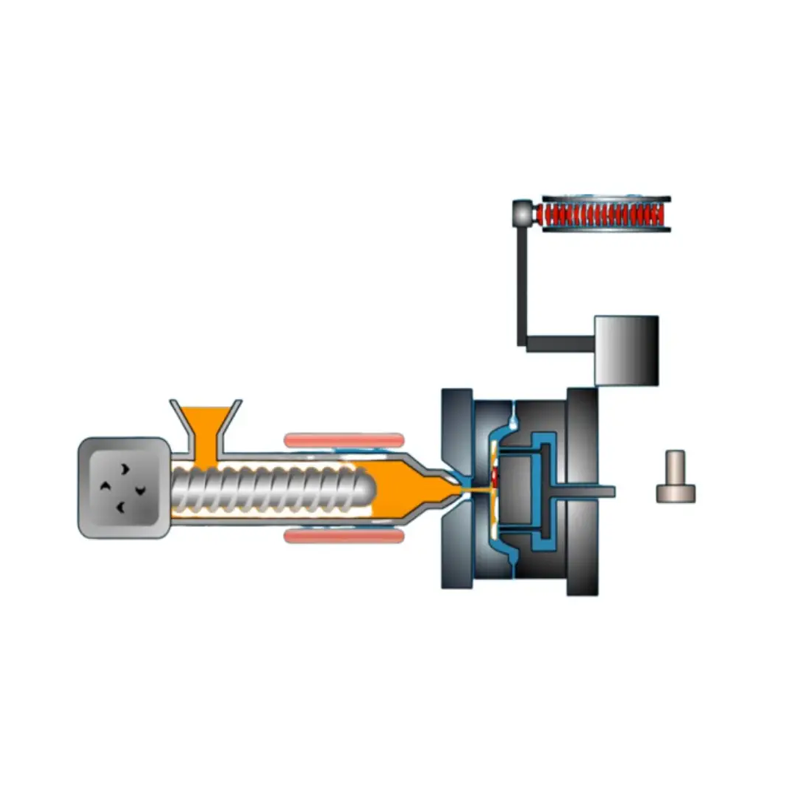

Injection Molding

Injection molding is the most common method for producing high-precision medical parts in large volumes. In this process, molten plastic is injected under high pressure into a precisely designed mold cavity. Once cooled, the material solidifies into the desired part.

This method is ideal for manufacturing medical products that require tight tolerances and consistency, such as syringes, vials, and surgical components.

-

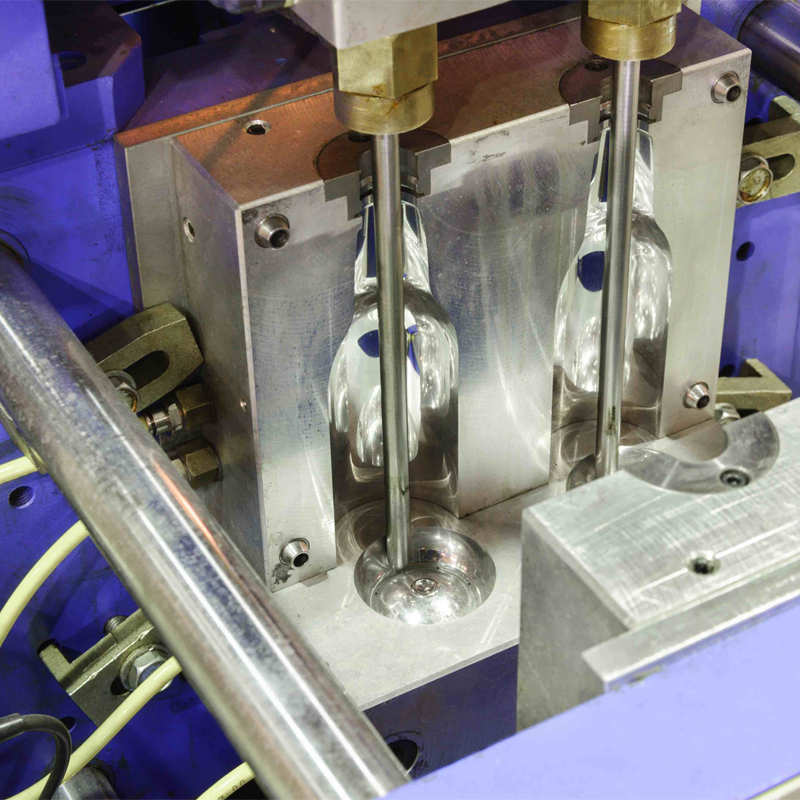

Blow Molding

Blow molding involves placing a molten plastic tube (parison) into a mold and using air pressure to expand the material into the mold cavity, forming a hollow part. This method is widely used to create medical-grade bottles, containers, and tubing.

Blow molding ensures uniform wall thickness and is perfect for producing lightweight components in large quantities.

-

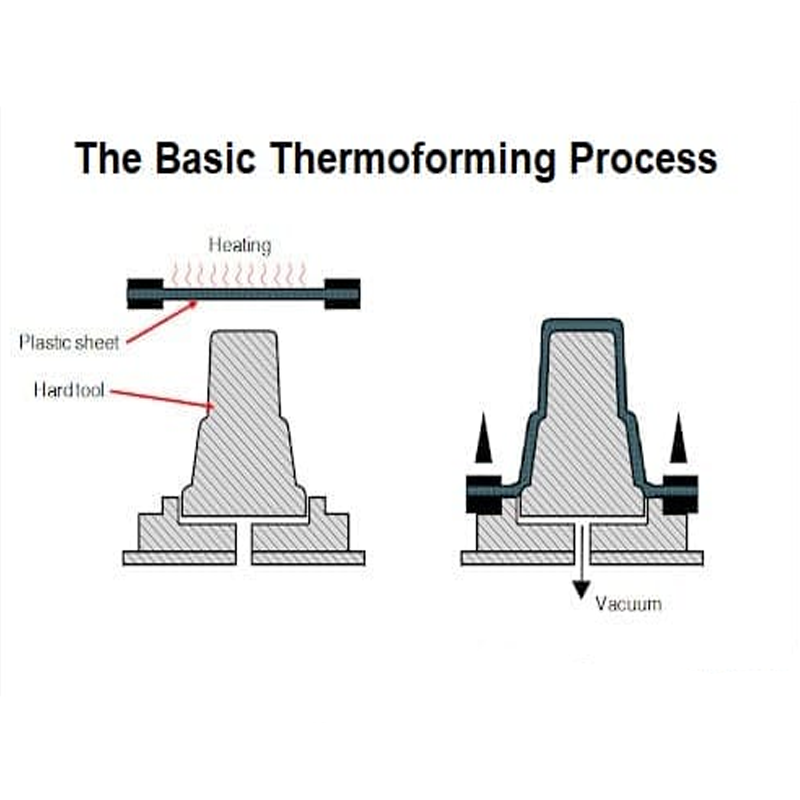

Thermoforming

Thermoforming involves heating a plastic sheet until it becomes pliable, then forming it into the desired shape using a mold. Once cooled, the part is trimmed to its final form.

This method is commonly used for medical trays, instrument packaging, and protective covers. Thermoforming is cost-effective and efficient for producing medium to large parts in relatively lower volumes compared to injection molding.

Types of Injection Molding Used in Medical Manufacturing

-

Standard Injection Molding

Standard injection molding is a versatile and cost-effective method for creating a wide range of plastic parts. It is the foundation of medical device manufacturing, enabling high-volume production with exceptional precision and repeatability.

-

Two-Shot Injection Molding

Two-shot molding combines two different materials or colors into a single part in one cycle. This process is ideal for producing medical components that require multi-material integration, such as grips, seals, or devices with both rigid and flexible sections.

-

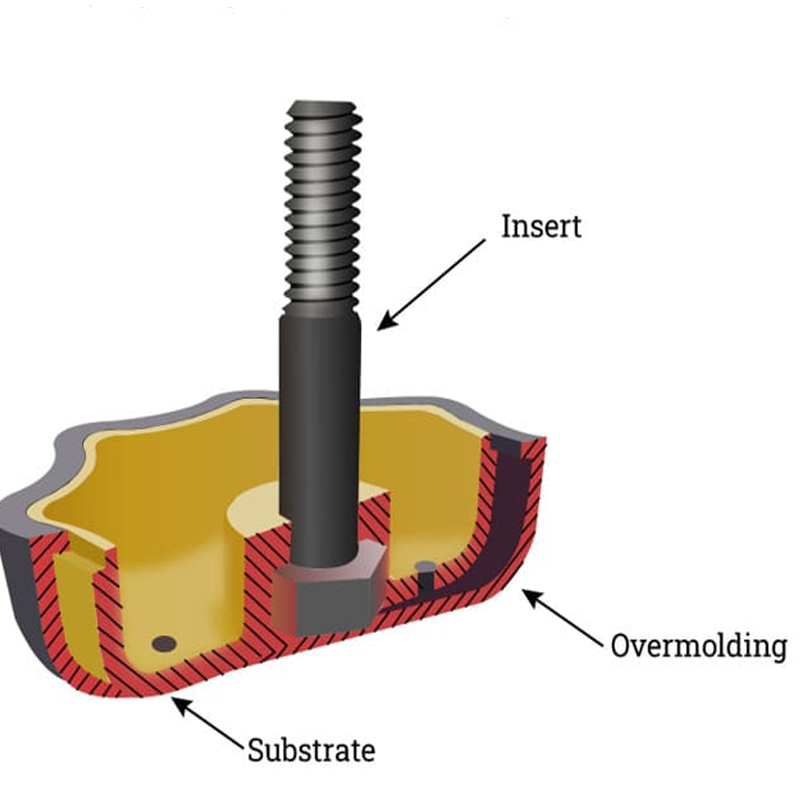

Insert Injection Molding

Insert molding integrates metal inserts, such as pins, connectors, or threaded parts, into a plastic mold to produce a single, robust component. This method is often used for connectors, surgical instruments, and medical device housings that require reliable metal-plastic bonding.

-

Overmolding

Overmolding involves injecting a second material over a pre-molded part to enhance functionality or ergonomics. This process is commonly used for creating handles, soft grips, and protective covers for medical tools and devices.

Common Plastic Injection Mold Styles

-

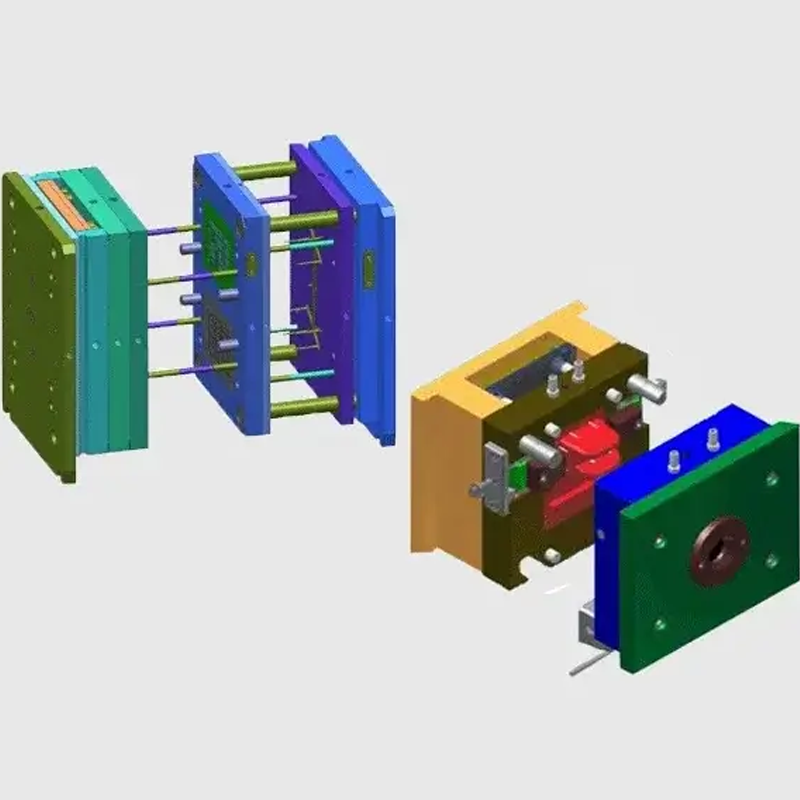

Two-Plate Mold

The two-plate mold is the simplest and most widely used injection mold structure. It consists of two main parts: the fixed (cavity) side and the movable (core) side. Gates, runners, and cavities are all on a single parting line.

Advantages of Two-Plate Molds:

– Simplified design for easy operation

– Lower manufacturing cost compared to complex molds

– Flexible gate location for better mold flow

– Shorter molding cycle and extended mold lifespan

Two-plate molds can incorporate complex structures such as sliders, lifters, and angle pins to accommodate intricate medical device designs.

-

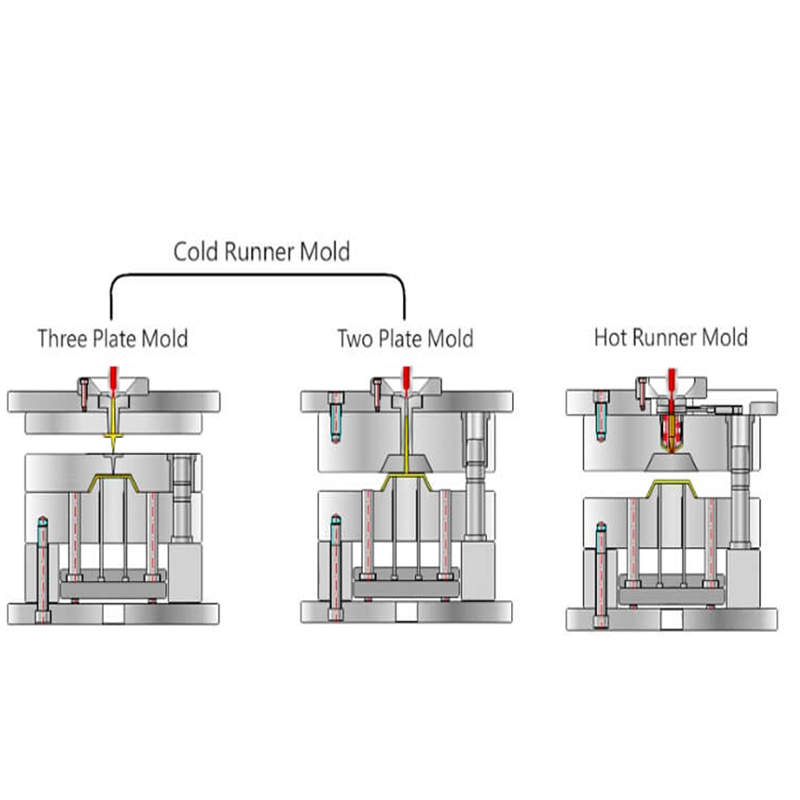

Three-Plate Mold

The three-plate mold features two parting lines and three sections, allowing the runner system to be located on a separate plane from the molded part. This setup enables automatic de-gating and improved design flexibility.

Advantages of Three-Plate Molds:

– Greater flexibility in gate location

– Elimination of manual gate removal

– Cost-effective alternative to hot-runner systems

Three-plate molds are ideal for medical components requiring multiple gates or complex geometries.

-

Reverse Mold

In reverse molding, the injection occurs from the ejector side of the mold rather than the cavity side. Special mechanisms, such as cylinders on ejector plates, are used to manage part ejection. This technique is particularly useful for parts with unique design requirements or challenging geometries.

Runner Systems: Cold Runner vs. Hot Runner

Cold Runner Systems

Cold runner molds rely on unheated channels to deliver molten plastic to the mold cavity. While simple and cost-effective, they result in material waste unless the excess can be recycled. Cold runner systems accommodate a wider range of polymers, including heat-sensitive materials.

Advantages of Cold Runner Systems:

– Lower initial tooling and maintenance costs

– Versatility with heat-sensitive plastics

– Simpler design for easy maintenance

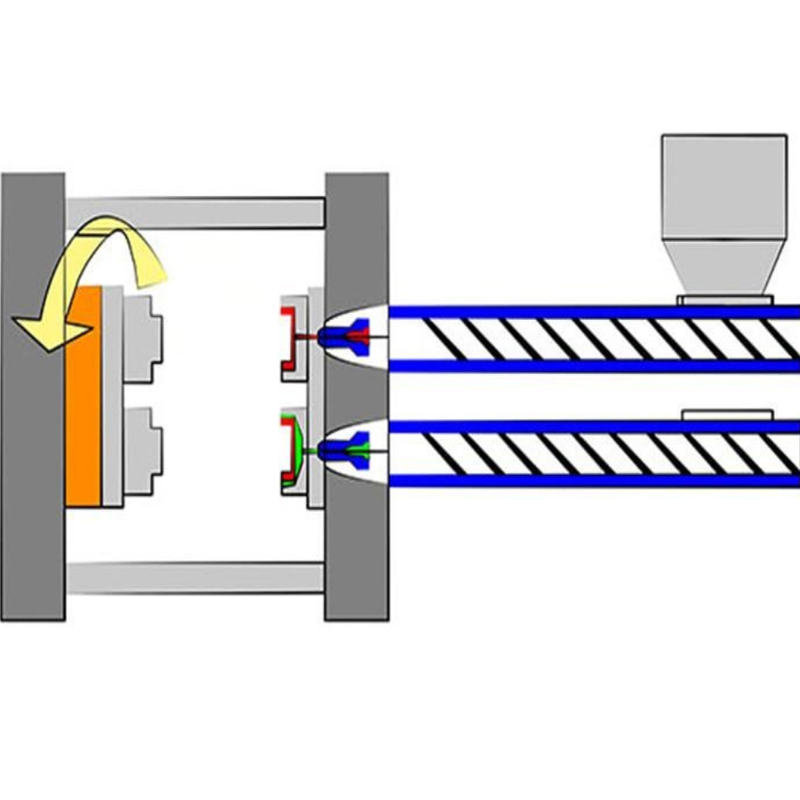

Hot Runner Systems

Hot runner systems utilize heated channels to maintain molten plastic flow throughout the molding process. Though more expensive, they minimize material waste, improve cycle times, and produce high-quality parts consistently.

Advantages of Hot Runner Systems:

– Reduced material waste for cost efficiency

– Faster cycle times for high-volume production

– Consistent part quality with enhanced control over material flow

Hot runner systems are ideal for medical devices requiring precision, complex geometries, and superior surface finishes.

Why Toolingsun is Your Partner for Medical Molding Solutions

At Toolingsun, we bring over 20 years of experience in mold design and manufacturing, specializing in advanced solutions for the medical device industry. Whether you require precision injection molding, insert molding, or overmolding, our expertise ensures superior performance, tight tolerances, and long-lasting quality.

We understand the unique challenges of medical device production, including strict regulatory standards and the need for reliable, high-performance components. Our team is committed to delivering innovative solutions tailored to your needs, from custom mold design to high-volume production.

Let’s Collaborate to Drive Innovation

Are you working on a new medical device project or looking to enhance your current production processes? At Toolingsun, we are ready to support your vision with cutting-edge mold technologies and proven expertise. Whether it’s precision molds for syringes, connectors, or surgical tools, we deliver exceptional results that meet your requirements.

Share your ideas or challenges with us—we’d love to collaborate and bring your project to life. Contact us today to learn more about our mold solutions, including metal stamping and metal stamped connectors, for the medical industry.Let Toolingsun help you achieve precision, quality, and innovation in medical device manufacturing.