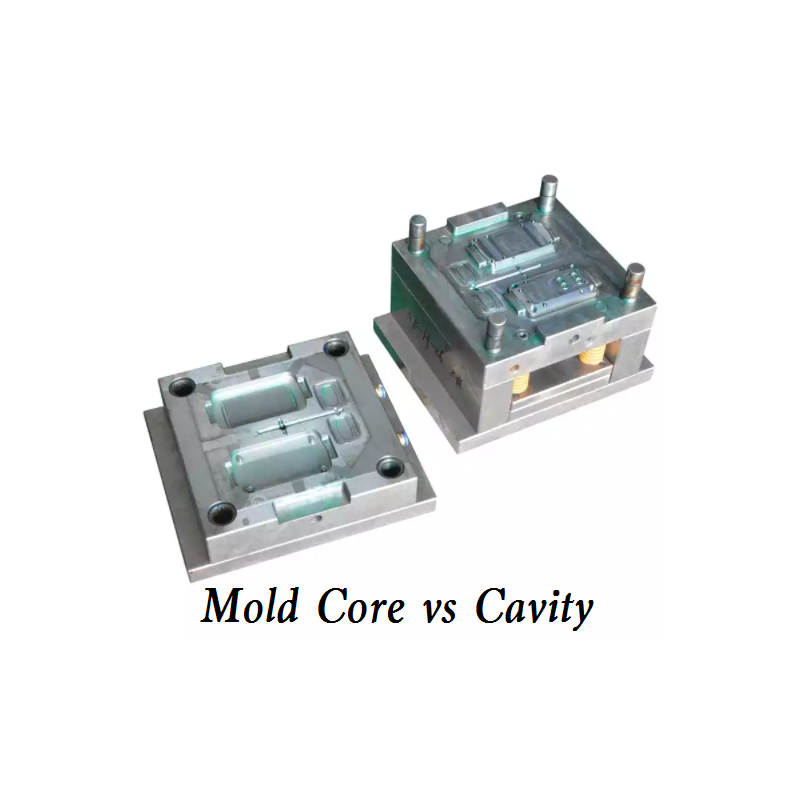

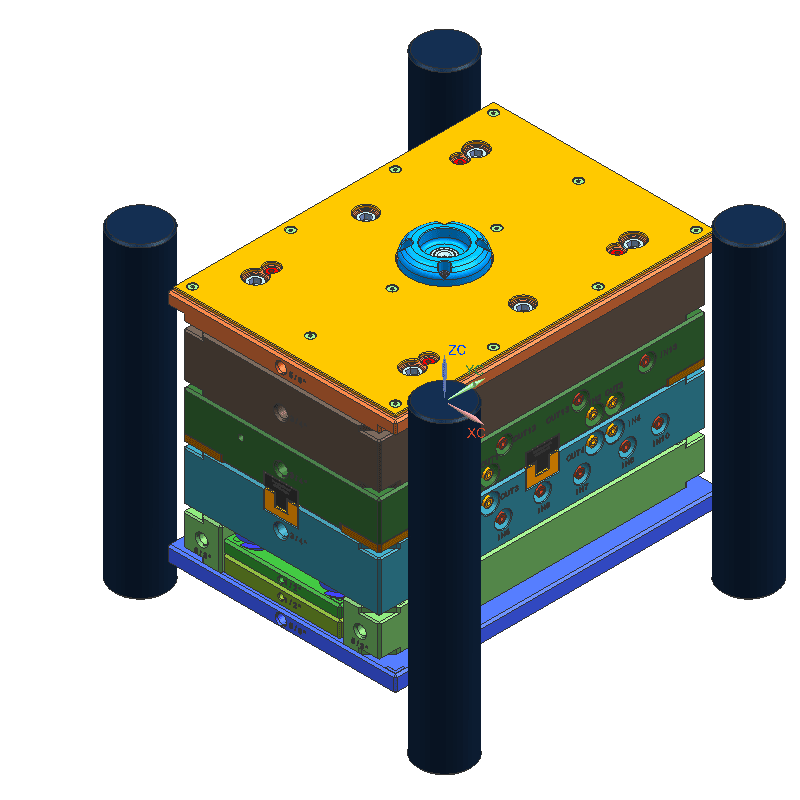

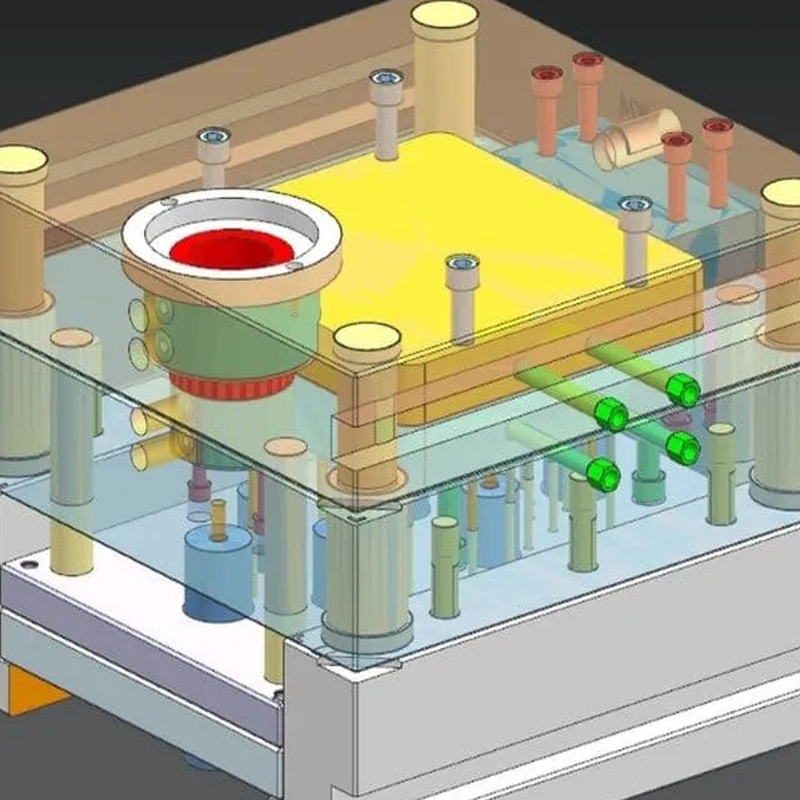

At Toolingsun, we understand that precise and thoughtful mold design is crucial to the quality and efficiency of manufacturing processes. One essential aspect of mold design that often goes underappreciated is the strategic clearance between components. Clearance is the gap or space designed between various parts of the mold to allow for proper movement, alignment, […]