Project Management for Plastic and Silicone Mold and Tooling

One-on-One Molding Services

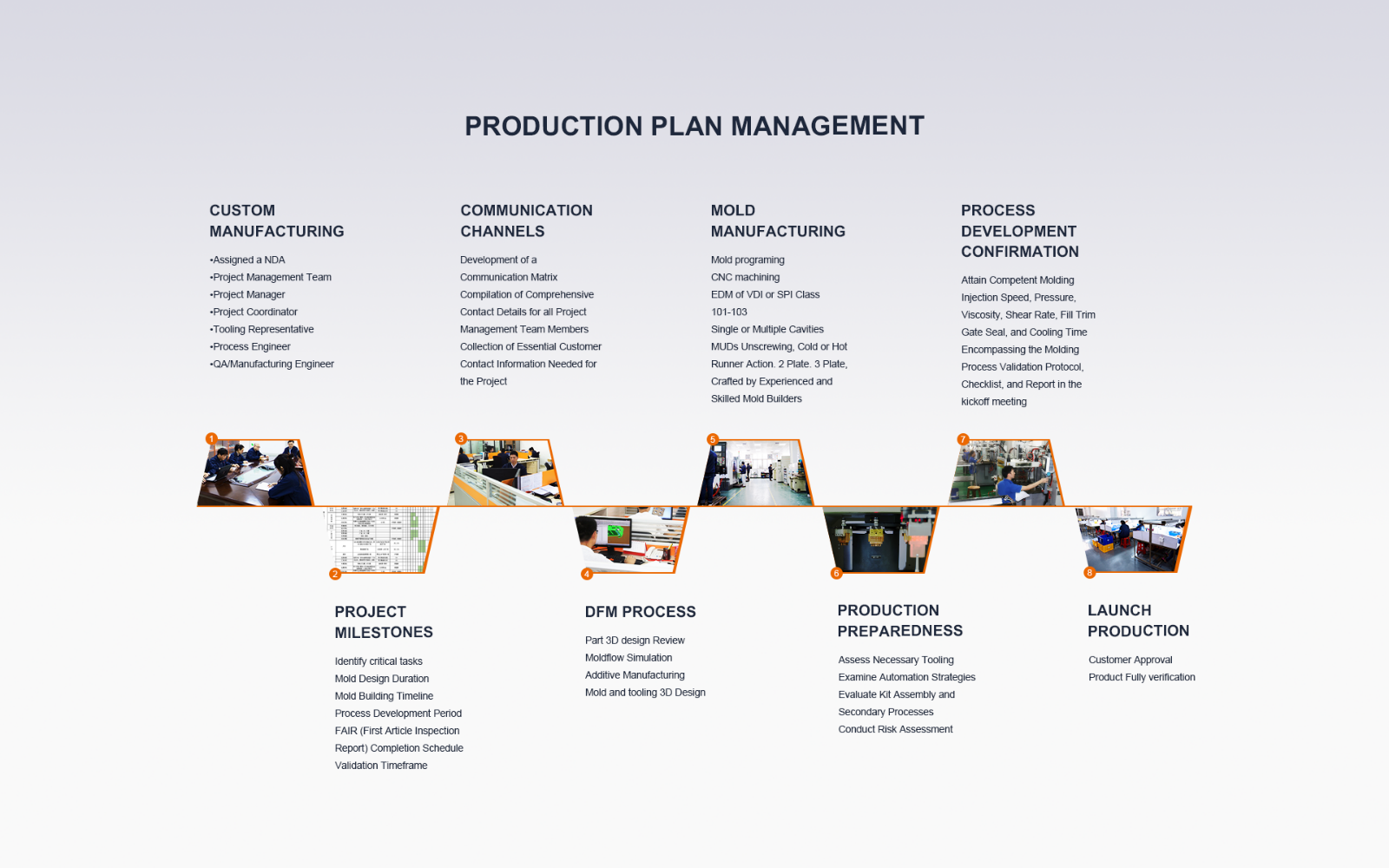

At Toolingusn, we ensure dedicated attention to each precision plastic injection molding project by assigning a dedicated Project Manager and Project Engineer to oversee the entire process. The Project Manager takes charge from the initial client discussions through to the successful completion of the project, offering clients a single point of contact throughout the entire journey.

In-depth Discussion Forum on Key Molding Service Elements

We will convene a series of roundtable discussions to delve into critical stages crucial for the success of plastic molding projects. These discussions will encompass various pivotal milestones such as project initiation, Design for Manufacturability (DFM), mold design, trial results, modifications, and more.

Mold Project Flow Chart

1. Customer Request: request for quotation (RFQ)

2.Purchase Order(PO)

3.Mold Design: design for manufacturability(DFM), pre-design, Moldflow, 3D mould design, design approval by customer

4. Mold Manufacturing: ordering steel, matching, mold assembling

5. Mold Trial: samples approval customer, modification

6. Shipping

7. After Sales Services

Project Management Team Ability

Efficient project management is pivotal in overseeing an injection molded project. The Project Management Team (PMT) comprises seasoned professionals dedicated to ensuring the project's alignment with customer-defined scope, quality benchmarks, and desired outcomes. Thus, the PMT commences its responsibilities by sourcing all necessary documentation, metrics, and directives essential for executing the project requirements seamlessly.

The PMT diligently monitors and oversees each task associated with the project, maintaining a cohesive approach from initiation to completion. This operational hub serves as a strategic facilitator, steering decisions and implementations consistently towards the customer-defined project objectives. Transparent and regular communication, both internally and externally, remains a cornerstone, enabling detailed reporting on all facets, including challenges, activities, and requisites integral to the project's success.

Early planning to Reducing Risk, Preventing Errors for Injection Mold Building

An effective PMT will engage in a manner that controls budgets, keeps projects on schedule, and will assure compliance with every mandate and requirement - be it regulatory or client-based. These actions serve to ensure a reduction of risk and the prevention of errors. It acts as a go-between with the client and the company, decreasing confusion, and increasing successful project completion. When done well - this process helps eliminate stress on the client because knowing the project will be completed on time. It increases accuracy and confirms the order of mandatory activities for increased speed and efficiency. In addition, they keep close tabs on all checks and balances.

Upon project initiation, a dedicated APQP team will be formed to conduct a comprehensive evaluation of project risks. This team will carefully scrutinize quotations, define actionable tasks and objectives, create the initial Bill of Materials (BOM), outline process flow charts, identify special product and process characteristics, and compile a risk assessment list.

Furthermore, this specialized team will perform a detailed analysis of various product structural designs and process technologies catered specifically to our clients. They will offer practical recommendations aimed at optimizing products, minimizing client expenses, boosting production capacity, and enhancing overall yield. Our goal is to work closely with clients, providing valuable insights that streamline operations and elevate the quality and efficiency of their projects.

Mold Development and Manufacturing for effective management

Our project team possesses the expertise to create comprehensive reports on mold manufacturability start-up design (DFM), conduct mold flow analyses, perform dimensional tolerance analyses, generate detailed mold design drawings and specifications, oversee mold production, conduct pilot production runs, manage mold corrections and engineering changes, conduct thorough 3D and 2D inspections, and handle mold acceptance.

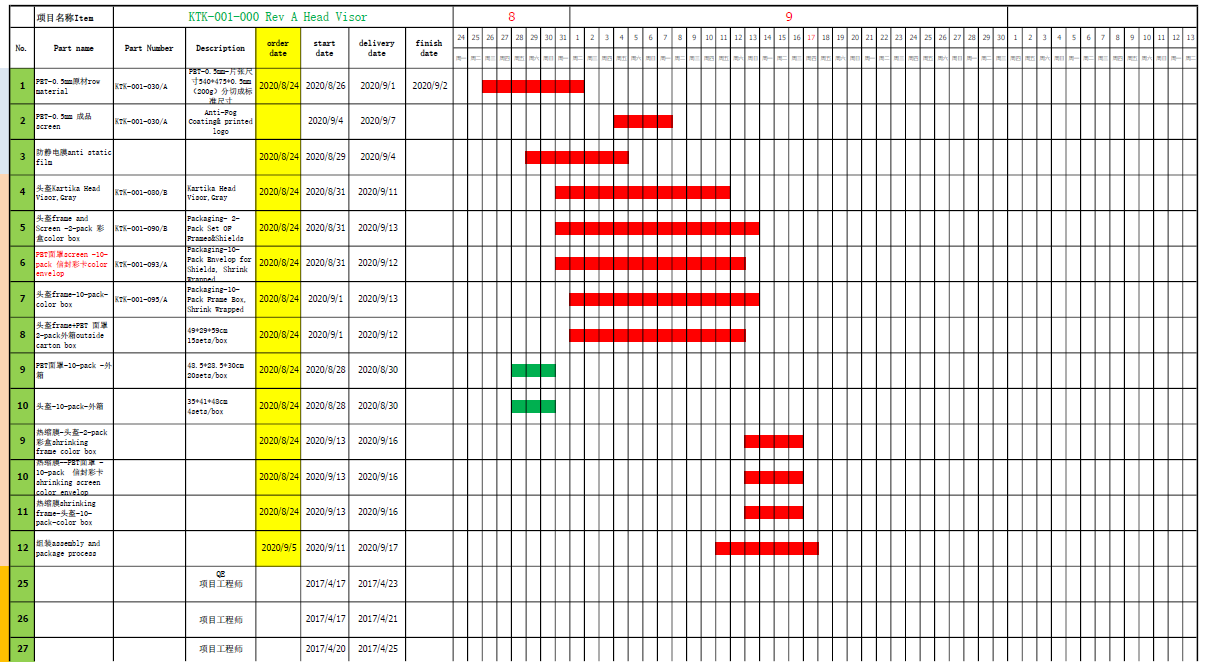

Efficient time management stands as a cornerstone of quality control and operational efficiency. It involves setting timelines that dictate when each team member completes tasks while ensuring an appropriate level of quality control. Time calculations account for unforeseen challenges, allocating time for their resolution. Accurate risk assessment is integral, ensuring that these risks are factored into schedules without compromising performance or quality. Communicating these risks and their solutions allows for review, analysis of patterns, trends, and opportunities among relevant stakeholders.

The team utilizes Gantt charts to monitor activities and time estimates. Each task is represented by a bar chart, detailing its start and end dates through its position and length.

In essence, the Gantt chart provides an at-a-glance view of:

Number of tasks within the project

Start and end dates for each task

Scheduled duration for each task

Overlap of responsibilities among tasks and their duration

Overall start and end dates for the entire project

In summary, the Gantt chart serves as a visual tool outlining tasks and their scheduled timelines, aiding in effective project management by highlighting what needs to be done and when.

Mold Design, Development, Approval and confirmation

Our expertise at Toolingsun encompasses a comprehensive range of specialized services for plastic injection molding projects. Your dedicated project manager possesses in-depth knowledge across all facets of our operations, ensuring optimal performance and efficiency in your project. Our seasoned and well-trained project managers offer:

Thorough examination through Design Failure Mode and Effects Analysis (DFMEA)

Guidance from Advanced Product Quality Planning (APQP) to complete Production Part Approval processes (PPAP)

Utilization of CAD and mold flow analysis to aid in product and mold tool design

Established partnerships with economical tool makers, ensuring projects stay within budget constraints

With a profound understanding of these specialized services, our project managers stand ready to provide expert advice and support, guaranteeing that your project benefits from our extensive experience and operates at its peak efficiency.

Mold and Part Delivery

The manufacturing process of custom injection molds and products demands meticulous attention and strategic planning. In this regard, effective communication takes precedence as the foremost responsibility of a project manager before addressing any other aspect of project management. This constant communication loop is established among design engineers, clients, production teams, mold builders, R&D experts, and manufacturing engineers.

Such ongoing communication fosters a comprehensive understanding of customer requirements and aids in devising improved methods to ensure timely product delivery. The linchpin for successful coordination in injection mold building lies in proficient project management.

Project management oversees the entire project lifecycle, initiating scheduling right from the project's inception through its transition into full-scale production.

Central to the role of a project manager is the meticulous scheduling and allocation of tasks, which are identified during the initial requirement assessment phase. Efficiently delegating various functions across different personnel within the organization is an integral aspect of this management approach. Continuous evaluation is crucial to monitor the progress of each task and provide regular reports to the client. Moreover, project managers are accountable for executing all decisions made by the Project Management Team (PMT).

At Toolingsun the Project Management Team (PMT) handles the management of new mold builds, tool transfers, and communicates project updates both internally and externally. Additionally, they oversee the project's scope, cost, and delivery using tools such as Gantt charts and a web-based project management server. To delve deeper into this process, we invite you to explore our webinar titled "Steps to Launching Your Injection Molded Project