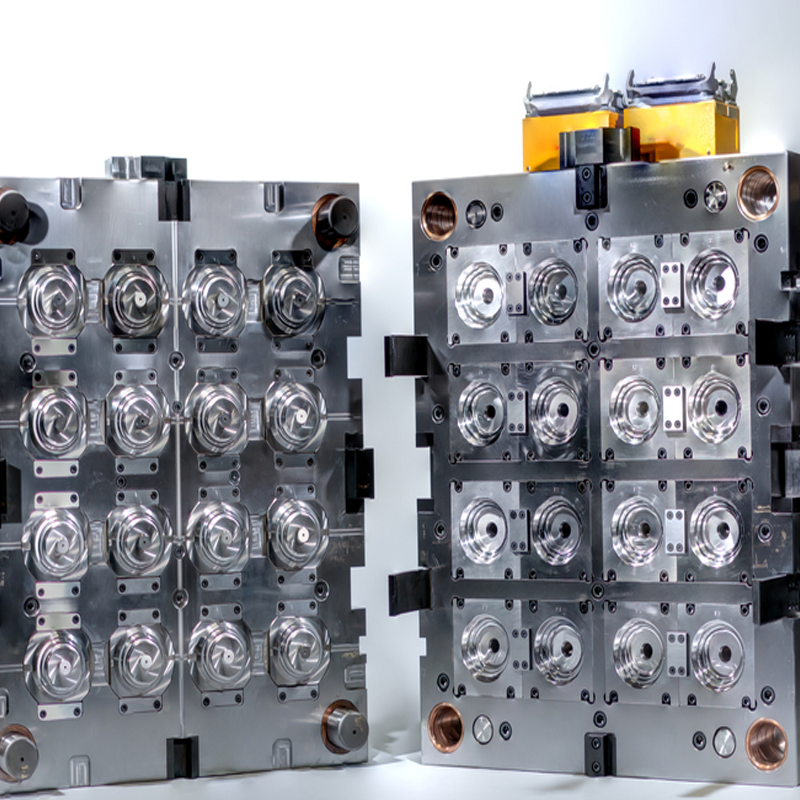

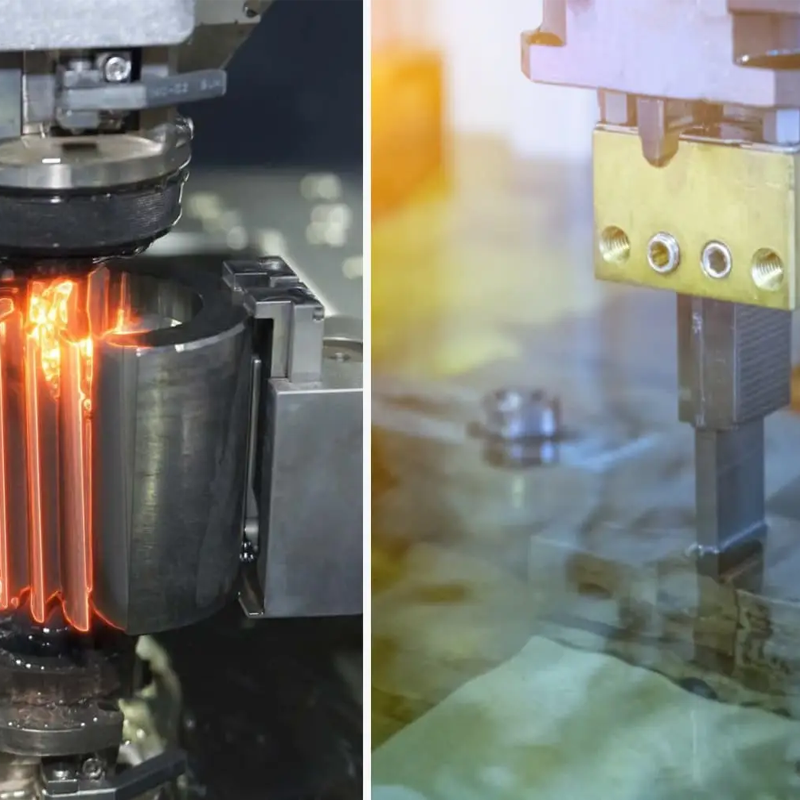

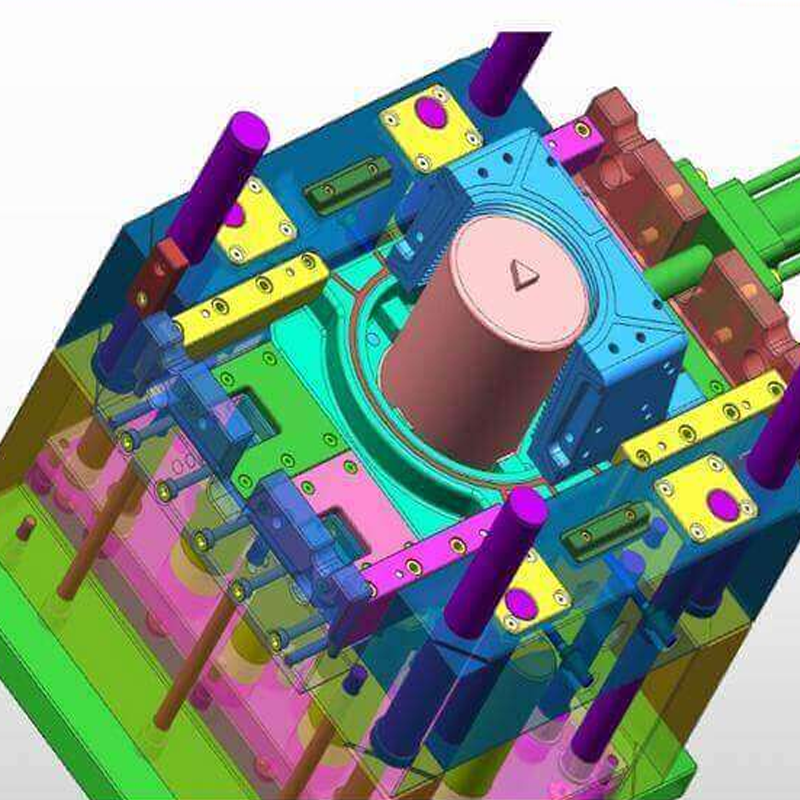

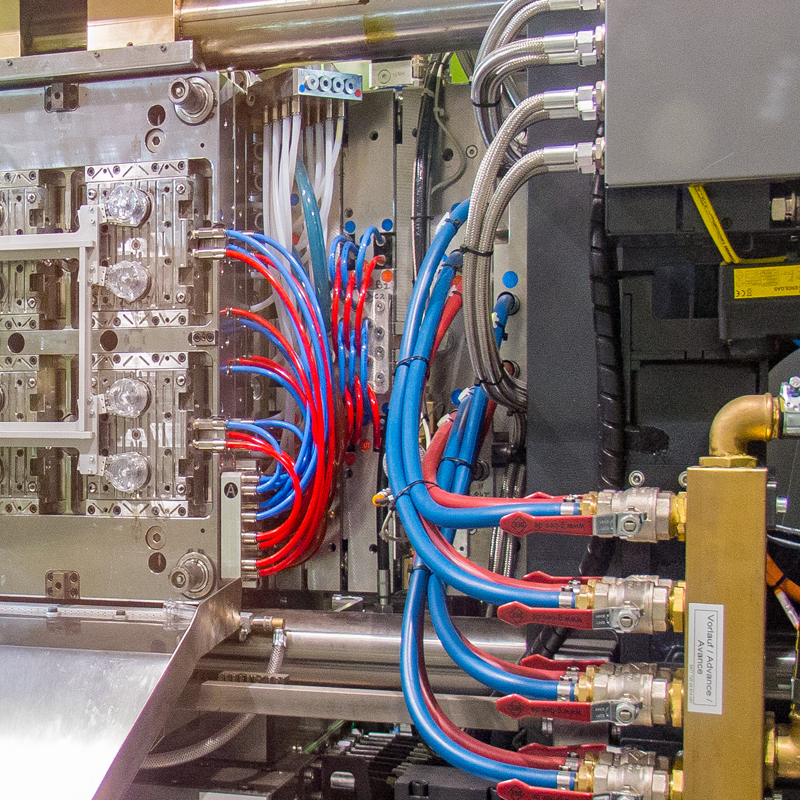

Injection mold tooling life is a crucial factor in the overall efficiency and cost-effectiveness of injection molding processes. It refers to the number of production cycles a plastic injection mold can complete before it requires maintenance, repair, or replacement. Each production cycle includes the process of closing the mold, injecting molten plastic, cooling, opening the […]