Every industry today relies on precision-manufactured plastic components, but selecting the right production method can be overwhelming. Should you choose CNC machining for its design flexibility, or is injection molding the better option for high-volume production? At Toolingsun, we understand the challenges of making this decision. This guide will help you navigate the differences between CNC machining and injection molding, ensuring you select the most efficient and cost-effective process for your project.

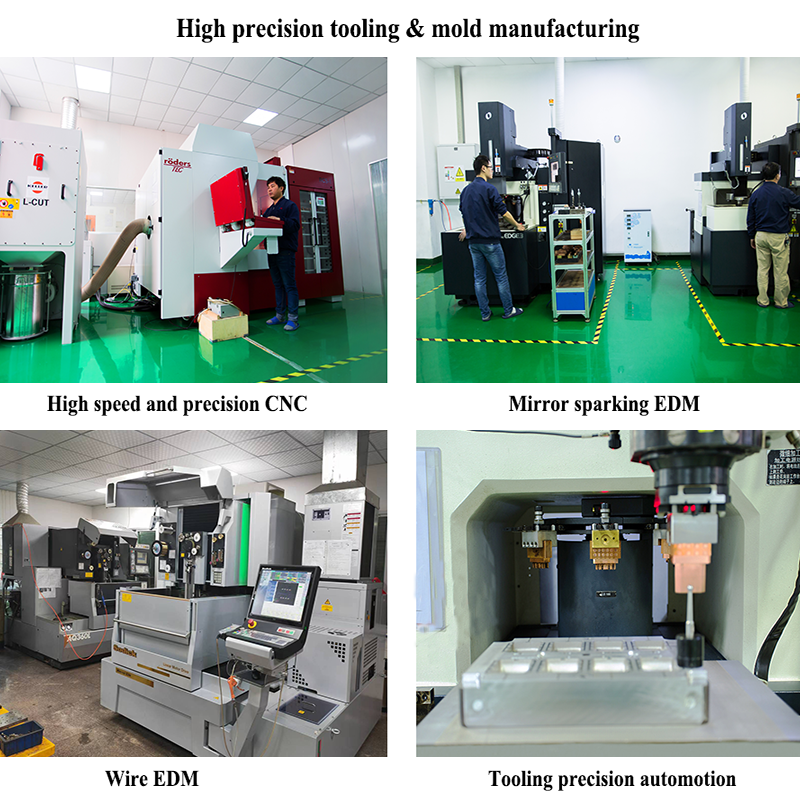

Understanding CNC Machining

CNC machining, or Computer Numerical Control machining, is a subtractive manufacturing process that removes material from a solid workpiece using pre-programmed software and cutting tools. This method is widely used for producing highly precise parts with complex geometries and tight tolerances.

Key Characteristics of CNC Machining:

- Material Versatility: CNC machining works with plastics, metals, and composites, making it ideal for applications requiring high-strength materials.

- Design Flexibility: Since designs are created using Computer-Aided Design (CAD) software, modifications can be made quickly without extensive retooling.

- Production Speed: CNC machining has shorter setup timesthan injection molding, making it ideal for rapid prototyping and low-volume production.

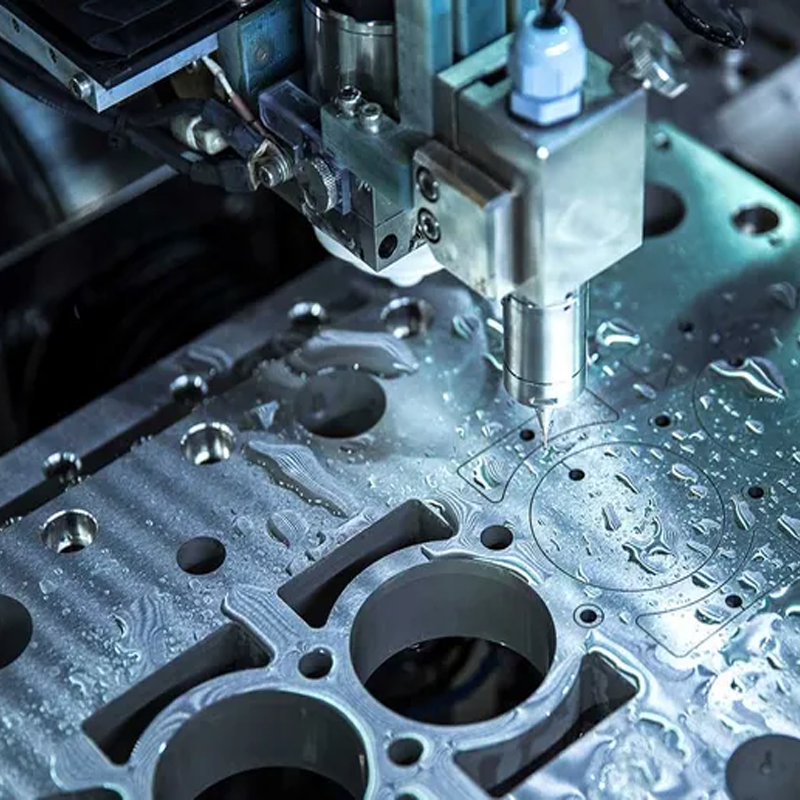

The CNC Machining Process

- Design Phase– Engineers create 2D or 3D CAD models of the part.

- Programming– The CAD design is converted into G-code, which directs the CNC machine.

- Material Selection– A workpiece is chosen based on the part’s requirements.

- Machining Execution– The CNC machine cuts, drills, or mills the material to shape the final part.

- Finishing and Inspection– The part undergoes deburring, surface finishing, and quality checks to meet specifications.

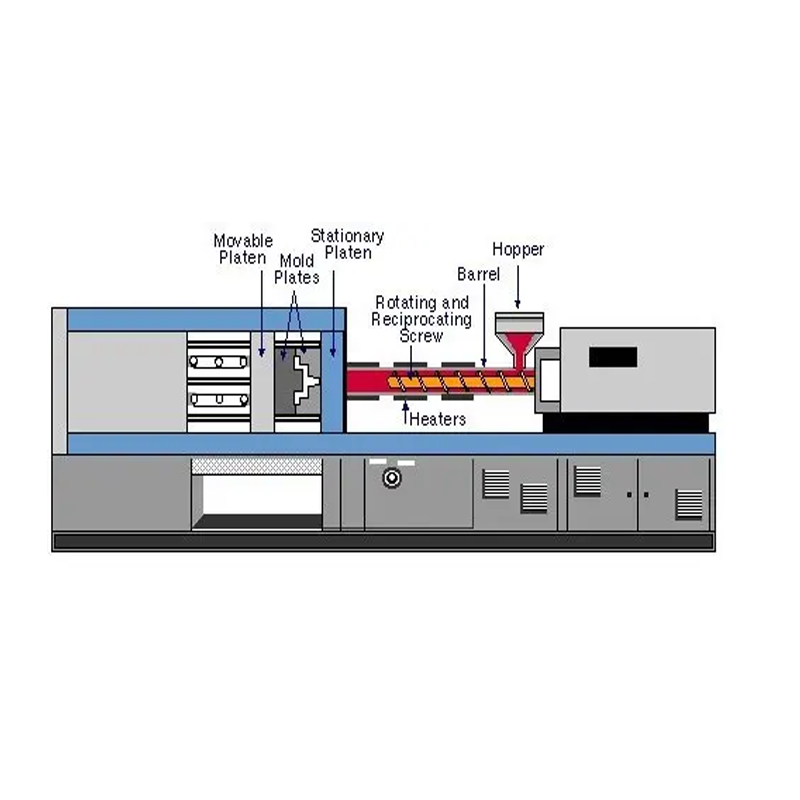

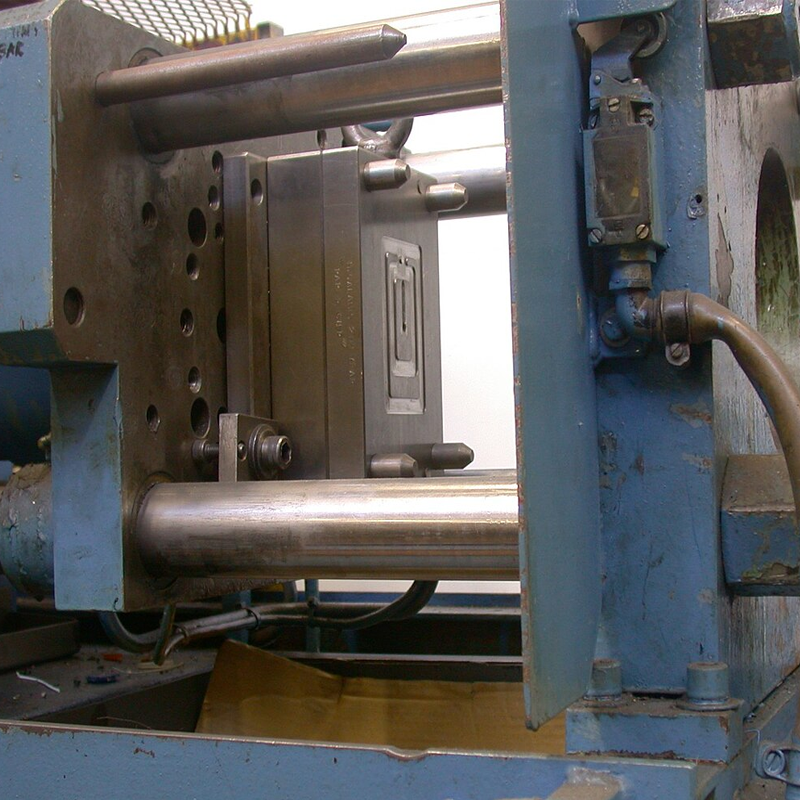

Understanding Injection Molding

Injection molding is a high-efficiency production process where molten plastic is injected into a mold cavity to form a final shape. This method is ideal for large-scale manufacturing of uniform plastic parts.

Key Characteristics of Injection Molding:

- Cost Efficiency for High Volumes: While the initial tooling cost is high, the per-unit cost decreases significantly for mass production.

- Material Waste Reduction: Unlike CNC machining, which removes material, injection molding uses only the necessary material, minimizing waste.

- Complex Geometry: Injection molding allows for intricate designs, internal cavities, and fine surface detailsthat would be challenging to achieve with machining.

The Injection Molding Process

- Mold Design & Fabrication– A precise mold is designed to match the part’s specifications.

- Material Melting & Injection– Plastic resin is heated and injected into the mold cavity under high pressure.

- Cooling & Solidification– The part cools and hardens into the final shape.

- Ejection & Finishing– The completed part is ejected, trimmed, and undergoes final quality checks.

Key Differences Between CNC Machining and Injection Molding

When choosing between CNC machining and injection molding, consider the following factors:

1. Cost Considerations

- CNC Machininghas lower initial costs but higher per-unit costs, making it more economical for small production runs or prototypes.

- Injection Moldingrequires a high upfront mold investment, but the per-part cost is significantly lower for high-volume production.

2. Design Flexibility

- CNC Machiningallows for quick design changes, making it ideal for custom parts, prototyping, and low-volume production.

- Injection Moldingrequires a finalized mold, meaning design changes after mold production can be expensive and time-consuming.

3. Lead Times & Production Speed

- CNC Machiningoffers faster setup times, allowing for quick prototyping and small-batch production. However, machining each part takes longer.

- Injection Moldinghas longer initial setup times, but once the mold is ready, production cycles are much faster, producing hundreds to thousands of parts per day.

Industry Applications

When to Choose CNC Machining

CNC machining is the go-to choice for industries requiring high-precision parts made from stronger materials, including:

- Aerospace: Engine mounts, landing gear components, and fuel flow parts.

- Automotive: Cylinder blocks, axles, dashboard panels, and gearboxes.

- Oil & Gas: Corrosion-resistant valves, pistons, rods, and cylinders.

When to Choose Injection Molding

Injection molding is ideal for large-scale plastic part production, particularly in:

- Medical & Pharmaceutical: Labware, diagnostic disposables, and orthopedic instruments.

- Consumer Electronics: Keyboards, phone cases, and wearable device components.

- Defense & Military: Handheld communication devices, weaponry, and decoy systems.

The Future of Manufacturing: Innovation & Sustainability

Both CNC machining and injection molding are evolving with new technological advancements that improve efficiency and sustainability:

- Industry 4.0 & Automation: Smart manufacturing with real-time remote monitoringand robotic automation.

- Sustainability Practices: Toolingsun is committed to reducing waste, recycling plastics, and using energy-efficient production techniquesto minimize environmental impact.

Making the Right Choice for Your Project

So, which method should you choose? The answer depends on your project’s volume, material requirements, budget, and design complexity. If you’re still unsure, Toolingsun is here to help. Our expert team specializes in both CNC machining and injection molding, ensuring you get the highest-quality parts at the most competitive cost.Contact us today to discuss your project and find the perfect manufacturing solution!