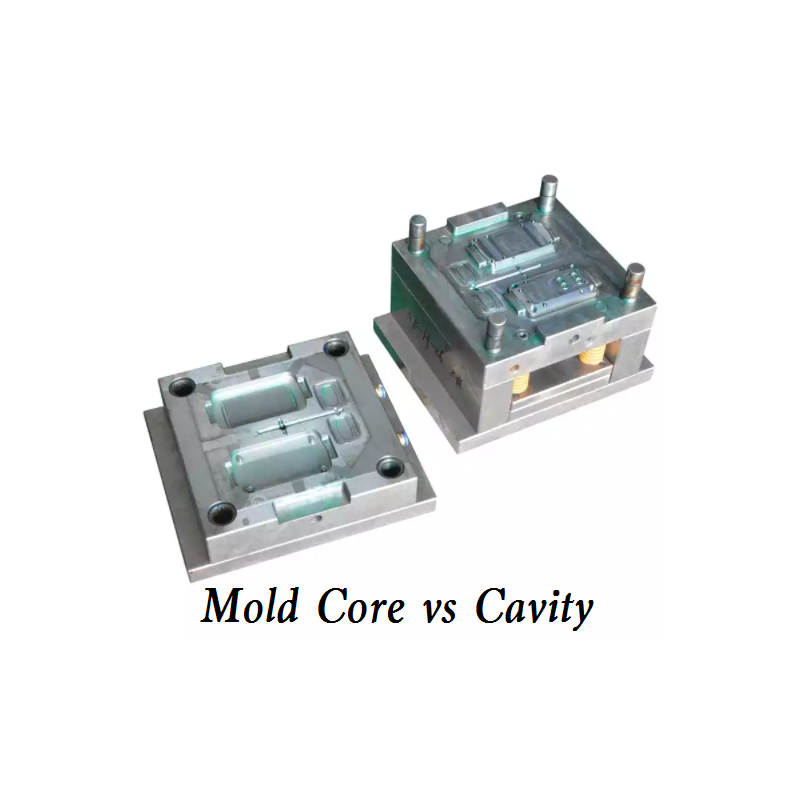

When it comes to injection molding, two key components play a crucial role in shaping the final product: the cavity and the core. At Toolingsun, we know that understanding how these parts work together is essential for achieving high-quality, precise results. In this blog, we’ll take an in-depth look at the differences between the cavity and core, explore their individual roles in the molding process, and discuss best practices for optimizing their design. Whether you’re a seasoned engineer or new to the world of injection molding, gaining a deeper understanding of these components will empower you to make informed decisions that enhance the efficiency and quality of your manufacturing process.

What is the Cavity in Injection Molding?

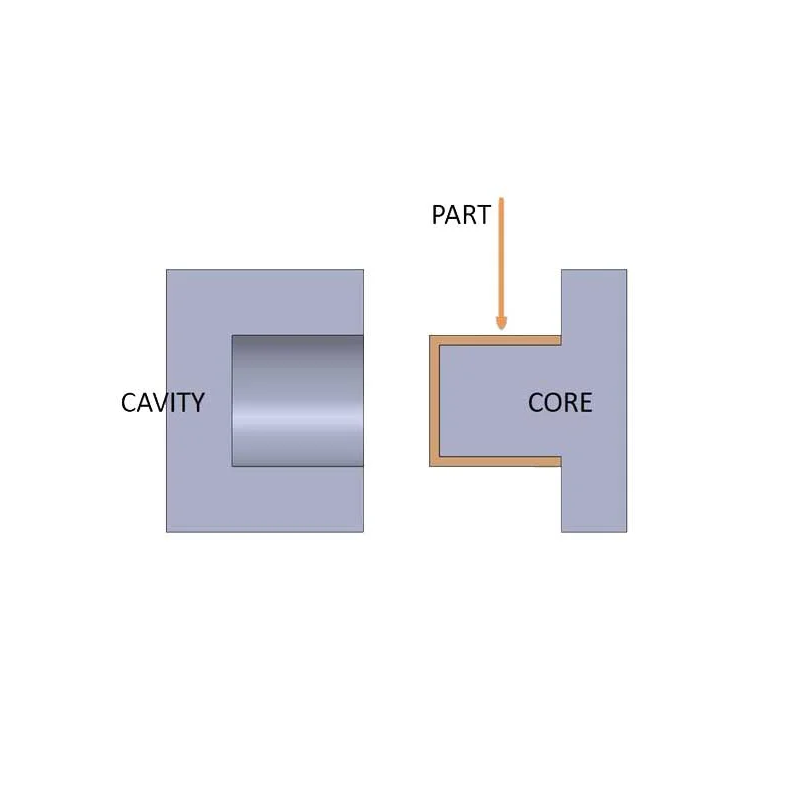

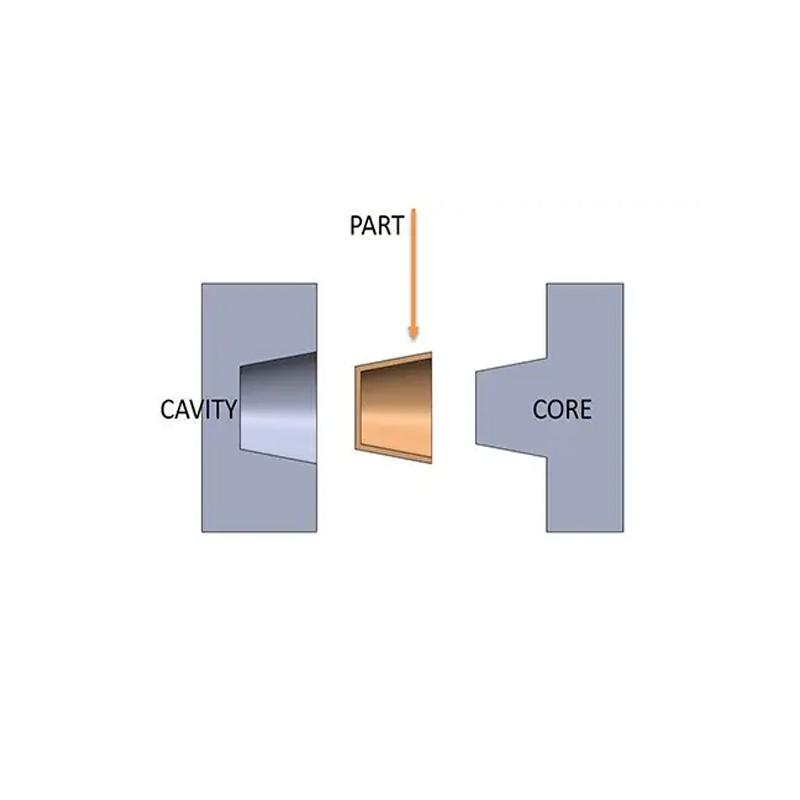

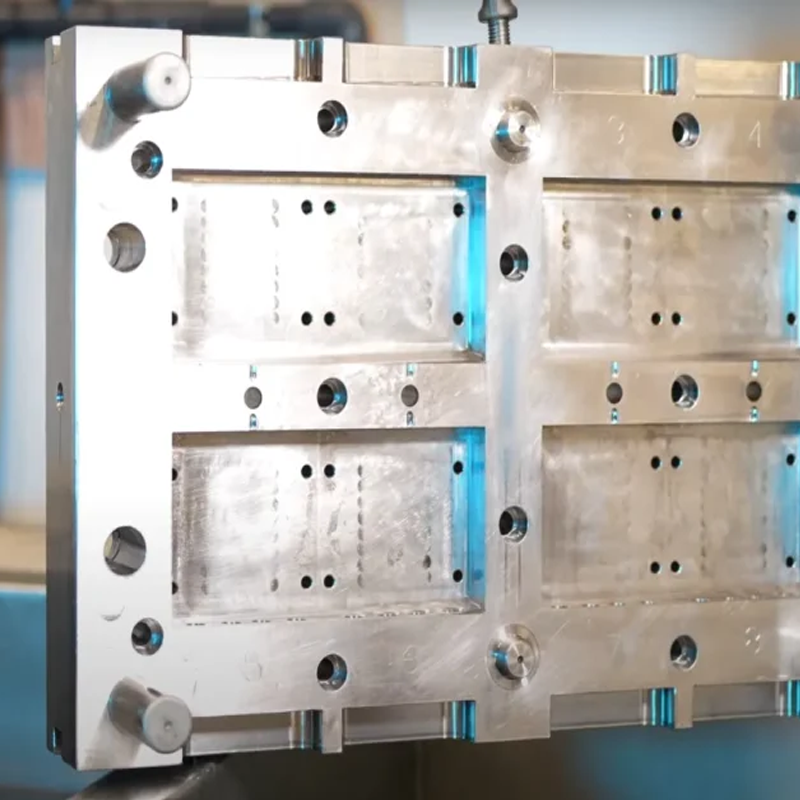

In injection molding, the cavity is the negative space inside the mold where the material is injected. It forms the external shape of the product, essentially acting as the mold’s “shell.” The cavity determines the outer dimensions and the final surface finish of the product. A well-designed cavity ensures that the molding material flows evenly throughout the mold, helping to achieve uniformity and high-quality output.

A few key considerations in cavity design include proper cooling and venting systems. Efficient cooling channels within the cavity ensure that the material solidifies at a consistent rate, preventing defects such as warping or sink marks. Proper venting is equally crucial, as it allows gases and trapped air to escape, avoiding issues like burn marks or incomplete parts.

Cavity design also directly impacts the overall speed and cost-effectiveness of the manufacturing process. Mold designers at Toolingsun carefully evaluate the part geometry to optimize the cavity design, ensuring the injection process is smooth and efficient. Our team uses advanced simulation tools to predict flow patterns and optimize cooling, which helps minimize cycle times and improve product consistency.

What is the Core in Injection Molding?

On the flip side, the core is the complementary part to the cavity, and it plays a critical role in shaping the interior of the product. While the cavity forms the exterior, the core defines the internal features of the mold. Think of the core as the “heart” of the injection mold—it forms features such as holes, cavities, threads, or undercuts that the cavity alone cannot produce.

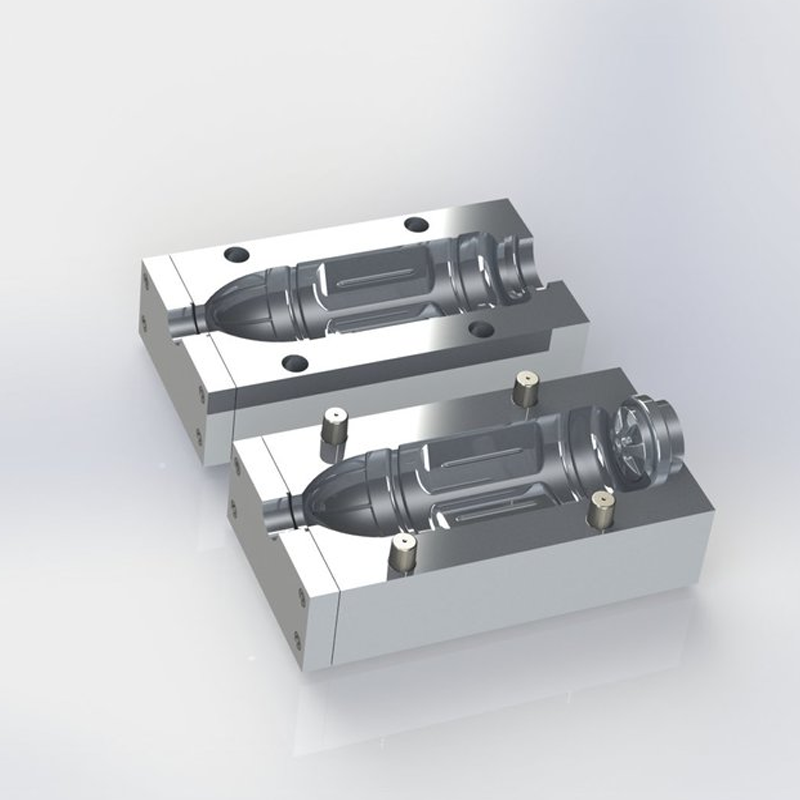

The core must be designed with extreme precision, especially when molding complex parts. The design of the core allows for the production of parts with intricate internal geometries, and it requires advanced technical knowledge to ensure that it works harmoniously with the cavity. At Toolingsun, we understand that creating cores for parts with complex geometries can be a challenge, which is why we focus on leveraging cutting-edge technologies to ensure that every detail is accurately formed.

Core design is a delicate balance—getting it wrong can lead to defects like excessive wear, difficulty in part ejection, or even the failure of the mold. That’s why Toolingsun’s experienced design team works closely with injection molders to develop a core that will seamlessly integrate with the cavity, ensuring flawless part production. By using technologies such as 3D printing and advanced CAD systems, we are able to create cores that can handle the most intricate shapes, all while maintaining product integrity.

Key Differences Between Cavity and Core

At first glance, the cavity and core may seem similar in that they both shape the product, but their functions are distinct. While the cavity creates the outer shape of the product, the core is responsible for forming the inner features. Here’s a breakdown of their primary differences:

– Cavity: Responsible for defining the outer dimensions of the product. It’s the “shell” of the mold.

– Core: Forms the internal features of the product, such as holes, cavities, threads, and undercuts.

– Design Complexity: The cavity design is typically more straightforward, while core design is often more complex due to the need for precise internal features.

– Cooling and Venting: Both components require efficient cooling and venting systems to ensure optimal results, but they each have unique cooling needs. The cavity requires uniform cooling to maintain the external shape, while the core often needs more specialized cooling to control internal features.

It’s clear that both components are essential for achieving high-quality products. When designed correctly, the cavity and core work together seamlessly to create a final product that meets both functional and aesthetic requirements. However, poor design or failure to align these components can lead to various issues, such as warping, sink marks, or part ejection problems. This highlights the importance of getting both components right from the very beginning.

Best Practices for Designing Cavity and Core

Designing the cavity and core for an injection mold is a precise and complex task that requires a deep understanding of both the molding process and the specific needs of the product. Here are some best practices that can help ensure success:

- Collaboration is Key

Communication between mold designers and injection molders is essential. It’s important to understand the specific requirements of the product and work together to ensure that the cavity and core are optimized for efficiency and quality.

- Utilize Advanced Technologies

Technologies like 3D printing, CAD software, and mold flow analysis tools can significantly enhance the design process. These tools help visualize and simulate the flow of material within the mold, ensuring that both the cavity and core are optimized for optimal performance.

- Consider Material Properties

Different materials behave differently during the injection molding process. Understanding the properties of the material being used is essential for designing the cavity and core. For example, materials with high shrinkage rates may require different cooling strategies to prevent defects.

- Ensure Proper Cooling and Venting

Both the cavity and core must be designed with efficient cooling channels to prevent uneven cooling, which can lead to defects. Venting must also be carefully planned to allow air to escape, reducing the risk of burn marks or incomplete fills.

- Account for Part Ejection

The design of both the cavity and core should facilitate easy part ejection. Undercuts, deep internal features, or tight tolerances may require additional mechanisms, such as ejector pins, to ensure smooth part removal.

By adhering to these best practices, manufacturers can avoid common pitfalls and ensure that both the cavity and core are optimized for efficient, high-quality production. At Toolingsun, we leverage our extensive experience and state-of-the-art technology to provide you with mold designs that meet the highest industry standards.

Conclusion:

Understanding the roles of the cavity and core is vital for ensuring the success of your injection molding projects. At Toolingsun, we prioritize precision in every aspect of mold design, ensuring that both components work together to create high-quality, functional products. Whether you’re looking to produce simple parts or complex geometries, our team has the expertise and technology to meet your needs.

We hope this deep dive into cavity and core design has provided valuable insights into the injection molding process. If you have questions or need expert guidance on your injection mold design, don’t hesitate to contact Toolingsun. Our team is always ready to assist you with any challenges you may face in your manufacturing process, ensuring that your projects are completed on time, within budget, and to the highest standards of quality.Let’s bring your designs to life—contact Toolingsun today to learn more about our mold-making capabilities and how we can support your next project!