Thermoplastic Injection Molding

What You Need to Know When Buying an Injection Mold

Lingshantech specializes in providing comprehensive production-grade injection molds crafted in our fully-owned manufacturing facility in China. These molds are intended for export and can be seamlessly integrated into your facilities or any designated manufacturing location of your choice. Our molds, specifically tailored to USA/Western standards, are meticulously designed for plastic and silicone production, ensuring optimal compatibility with your existing injection molding machines. They come equipped with pre-configured cooling line connections, streamlining the setup process for your operations.

We understand that each customer may have unique tooling needs. Hence, we offer customization options to align with your specific requirements, encompassing the choice of steel, hot & cool runner systems, molding processes, and surface finishes or textures for the injection molds. Our approach also involves incorporating your functional preferences into both mold designs and injection molding processes. Upon completion, we facilitate pilot and short production runs, serving as an effective solution for addressing any transitional tooling gaps in your production.

In essence, Lingshantech's offering revolves around providing tailored, high-quality injection molds designed to match your individual specifications, ensuring seamless integration into your manufacturing processes and enabling efficient production runs.

Quality Matters, and Not All Mold Makers Are the Same

Selecting a reliable mold maker is crucial when investing in injection molds due to their substantial cost. Ensuring that the mold precisely adheres to specifications is paramount, as even minor deviations can lead to issues such as flash—where material leaks at the mold's junction points. This can significantly impact the final product's quality, potentially necessitating additional time for post-production cleanup. Additionally, the choice of materials used in mold production should be carefully considered to guarantee optimal quality.

Mold Durability

The injection molding process subjects molds to substantial stress, leading to wear and tear over successive cycles. Various factors influence the longevity of your injection mold, including the use of robust, higher-grade steel. Moreover, molds are engineered to operate within precise pressure and temperature parameters, deviation from which can accelerate their deterioration.

By entrusting us with your part molding needs, you benefit from our commitment to ensuring the longevity of the molds. We offer comprehensive support, including repair, refurbishment, or potential replacement of molds at our expense, as long as you continue utilizing our molding services. This proactive approach safeguards your investment and guarantees continuous, high-quality production of your parts.

Several factors influence the durability of molds:

Material Quality: Using high-grade, durable steel in mold construction enhances its resilience to wear over time.

Operational Parameters: Adhering to specified pressure and temperature ranges during molding processes helps prolong mold life. Deviating from these parameters can expedite wear and reduce durability.

Proper Maintenance: Regular cleaning, lubrication, and maintenance routines are crucial for preserving mold integrity and prolonging its lifespan.

Design Considerations: Molds should be intricately designed, especially for complex parts or family molds, to ensure balanced filling and reduced stress on the mold components, thereby enhancing durability.

Mold Treatments: Surface treatments, coatings, or heat treatments can be applied to molds to improve their resistance to wear and increase durability.

Manufacturer Support: Having a manufacturer or supplier willing to provide repair, refurbishment, or replacement services can significantly contribute to extending the mold's life and maintaining consistent production quality.

Ensuring the proper design of complex injection molds is paramount

Ensuring the proper design of complex injection molds is paramount. While numerous injection molders exist worldwide, not all possess the same level of design expertise. It requires a company with extensive experience and knowledge to guarantee the efficacy of an injection mold.

Take, for instance, family molds, which generate multiple parts simultaneously. It's crucial that these molds are meticulously balanced. Improperly made family molds can result in short shot parts (incomplete) or flash, which can significantly impact production by necessitating additional time for part trimming.

The key lies in entrusting your complex injection mold needs to a seasoned company with a proven track record of design excellence. Such expertise ensures that the molds are not just constructed to specification but are also intricately designed to function optimally, minimizing the risk of production issues and maximizing efficiency.

The importance of injection molds for achieving successful mass production

Investing in tooling stands as a critical cornerstone for achieving successful mass production. Over the operational lifespan of an injection molding tool, it undergoes wear and tear from the repeated injection of high-pressure molten plastic. These tools are engineered to withstand extensive use, and the ones we create for our clients are built to last up to one million shots.

Injection molds are intricate and intricate devices, comprising injection, ejection, cooling, and heating systems. Given their rigorous operational demands, constructing these tools demands a significant investment of time, labor, and materials. The craft of tool making demands unparalleled precision; top-notch tool making involves crafting tools with an accuracy within 0.03mm to prevent part flashing. Generally, these tools entail substantial costs in the thousands of dollars. However, the outcome of this substantial investment yields components that can be mass-produced for mere dollars or even cents.

Allocating more resources toward superior quality or advanced tooling offers several advantages:

Safeguarding the consistent production of high-quality components over an extended period.

Ensuring ease of repair, thus prolonging the tool's operational lifespan.

Minimizing the possibility of extended downtime for the tool during repairs.

Reducing the overall cost of molded components through faster cycle times, lower reject rates, and decreased post-processing or finishing requirements, such as trimming of flashing or sprues.

Ultimately, the upfront investment in high-quality tooling promises long-term benefits by enhancing production efficiency, maintaining product quality, and driving down production costs in the long run.

Beware of Buying Directly from Overseas

While reducing costs by sourcing directly from overseas might seem appealing, it can pose several challenges. Two issues are language barriers and time zone differences. Communication difficulties due to language barriers and varying work hours may lead to project delays.

At Lingshantech, we acknowledge these challenges and possess the capability to address them. With extensive experience in mold manufacturing and proficient English communication skills, we ensure seamless communication without language barriers. You'll be assigned a proficient English-speaking project manager to facilitate smooth communication within our regular business hours, reducing time costs associated with communication and exchanges.

Another concern with direct overseas injection mold manufacturers might be inconsistent quality. However, as an injection mold manufacturer with our own manufacturing plant in China, our internal quality assurance team guarantees the highest standards for the molds we deliver. This means you can trust in the reliability and conformity of the molds we export, reducing quality concerns and ensuring process stability.

In summary, we emphasize our strengths in overcoming language and time zone barriers, and highlight our internal quality assurance measures with a manufacturing plant in China to ensure high-quality, reliable molds for export.

Injection Molding Part Production

In addition to manufacturing and shipping injection molds directly to our customers, we also offer the service of producing plastic parts using these molds in our own facility. Opting for us to handle the injection molding of your parts comes with the added advantage of our lifetime guarantee. While we're actively involved in producing your parts, we take responsibility for the upkeep, repair, and potential replacement of the mold, all at our expense if necessary. This commitment ensures that your production remains seamless and worry-free as long as we continue to manufacture your parts.

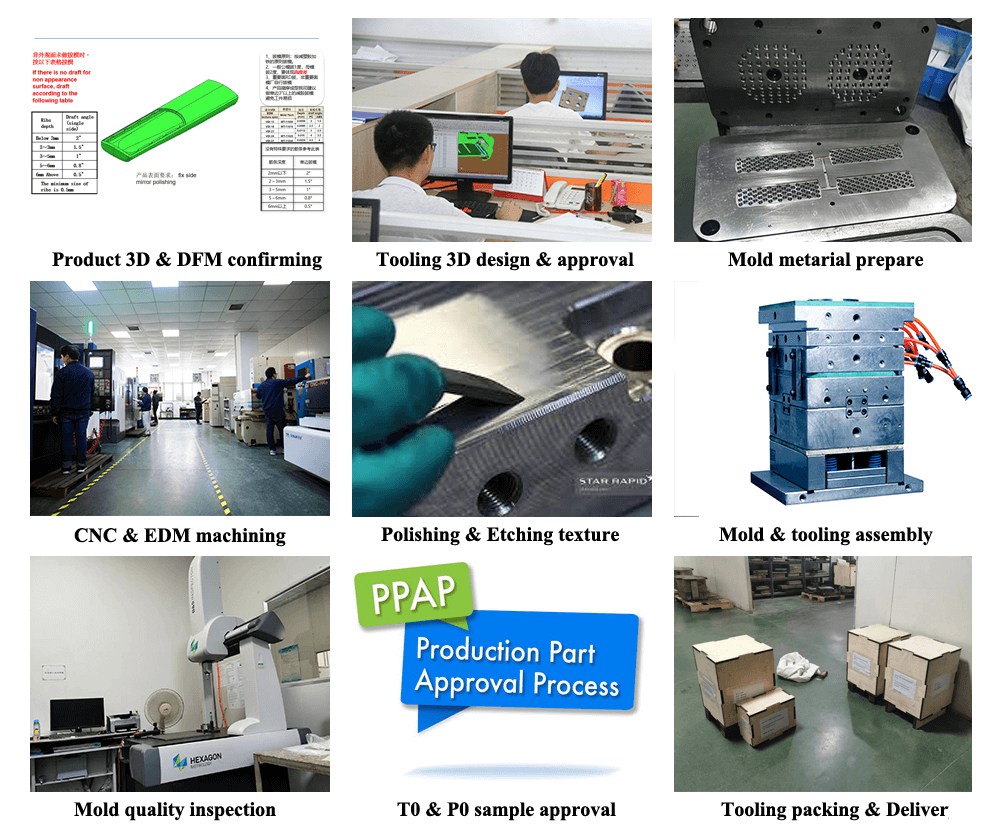

Process for Export Injection Mold

Our quote form and mold frame sharing technology enables us to simplify and shorten both the quoting and tooling manufacturing process for plastic injection molding.

1, Send us your 3D drawing with the format of step, stp, x_t, pro-e .

2, Upon confirming your order, we initiate the export mold order process.

3, we will design the tooling 3D and review several times in our team.

3, You'll be provided with the 3D comprehensive mold design for your review and approval.

4, After your approval of the tooling 3D design, we begins builing your injection mold.

5, We proceed with sample testing and pilot production.

6, Finally, we deliver the completed tooling to your specified location.

This efficient process ensures a swift and efficient journey from initial file submission to the delivery of high-quality injection molds tailored to your specifications.

Export Injection Mold

> Built to your specifications

> Low cost, quick build and high quality

> Mold tooling shipped to you or your production facility

You can get very good quality tools if you can design the tool to the style and specification you specifically need, and you know which specific steel suppliers and grades to use for tooling steel.

We specialize in exporting injection molds tailored precisely to your requirements. Our focus is on providing a combination of affordability, rapid production, and uncompromised quality. Whether shipping directly to you or your production facility, our mold tooling meets your specifications.

Explore our plastic injection molding and CNC machining case studies to witness how we've successfully assisted numerous clients with their projects.

It's vital to debunk the misconception that sourcing tooling from China implies inferior quality. Chinese tool makers are often highly skilled, with many receiving training from American-owned companies. The key to obtaining excellent quality tools lies in designing them to your specific needs and understanding the ideal steel suppliers and grades for tooling steel.

By aligning your tool design precisely with your specifications and leveraging knowledge of specific steel suppliers and grades for tooling steel, you can obtain exceptionally high-quality tools.

How to work with us for your molds & tooling

Lingshantech boasts two decades of expertise in plastic and silicone injection molding services. Over this time, we have continually refined our mold design techniques and optimized production processes. Presently, we have established a highly reliable production and processing system, delivering top-notch plastic mold and plastic injection molding services to our clientele.

From the initial quotation to the final mold shipping stage, each step of production undergoes meticulous planning at Lingshantech. We conduct internal meetings involving our tool design team, raw material procurement, and processing departments to offer our clients competitive unit prices for plastic tooling and injection parts. Simultaneously, our customers provide essential information, including injection machine data, resin data sheets, and mold standard requirements.

At Lingshantech, we prioritize meeting precision requirements for plastic molds and parts. Our state-of-the-art in-house CNC machines enable us to achieve a mold tolerance as precise as +-0.005mm. Particularly for high precision medical plastic molds and those with numerous cavities, we ensure stringent accuracy. Additionally, we specialize in producing high precision components like mold sliders, cavity blocks, and core blocks, adhering to our customers' drawings with 100% accuracy.

FAQS

Q: What is your production lead time?

A:Our standard lead time for mold production is 4-8 weeks or depending on the complexity of the part. For plastic molded parts is 15-25 days depending on your quantity requirements.

Q: What is your payment term?

A: 50% as payment deposit, 50% balance will be paid before shipping. For small amount, we accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred.

Q: How do you deliver the goods?

A: We have our own logistics department that could provide shipping costs via Sea or Air freight, Incoterms EXW, FOB, etc. Or we can work with your appointed shipping forwarder.

Q: How can I guarantee our quality?

A: During mold fabrication, we inspect materials and parts. In part production, we conduct a 100% full-quality inspection before packaging, rejecting any parts that don't meet our or client-approved quality standards.