Affordable Tooling Mold for Auto Parts from Chinese Factory

Characteristics:

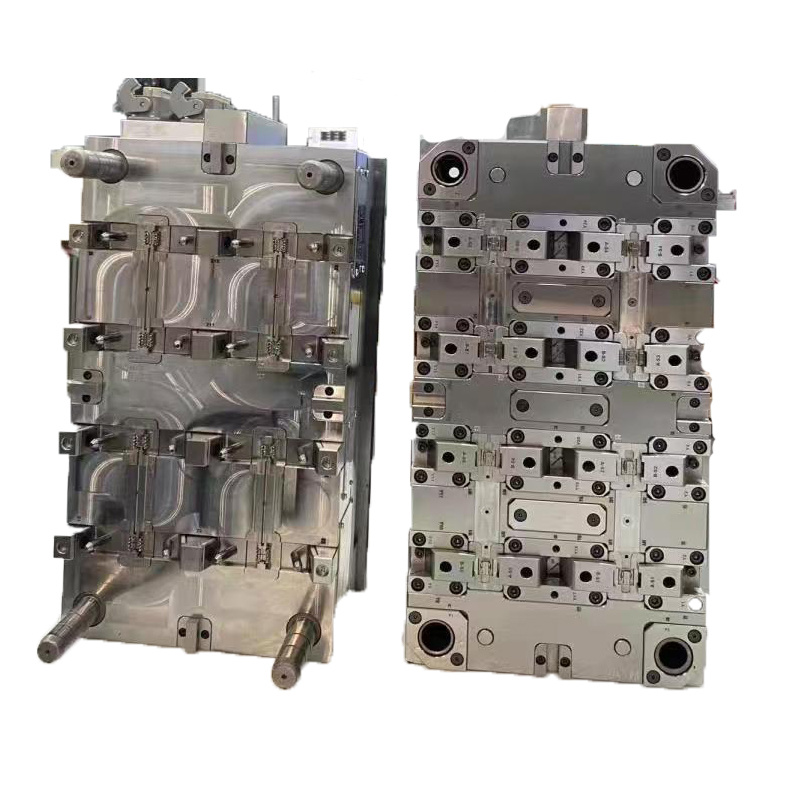

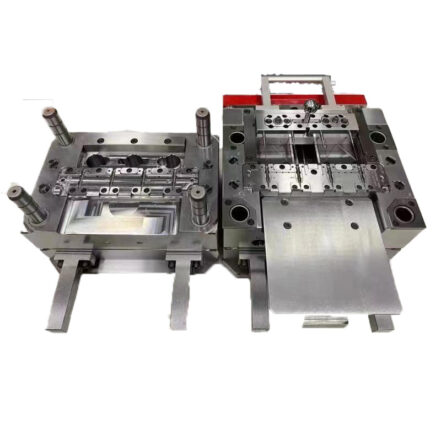

| Features | Details |

| Place of Origin | Xiamen, China |

| Service | OEM/ODM |

| Product Material | Steel |

| Shaping Mode | Plastic Injection Mould |

| Injection Material | ABS, PP, PS, PE, PVC, PA6, PA66, etc. |

| Mould Material | P20, 718, 738, NAK80, S136, 2738, 2316 |

| Mold Base | LKM, HASCO, DME, or Chinese Standard |

| Tolerance | 0.003mm – 0.01mm |

| Drawing Format | STEP, STP, IGS, X-T, STL, CAD, PDF, DWG, and others |

| Mold Life | 500,000 shots |

| Runner | Hot Runner or Cold Runner |

| Warranty | One Year |

| Mold Cavity | Single or Multi-cavity |

Manufacturing Process:

- Design and Engineering

– Description: Develop detailed CAD designs and engineering drawings tailored to the specific requirements of automotive components, ensuring precision and functionality.

- Tooling and Die Preparation

– Description: Fabricate metal stamping dies using high-precision machinery, including EDM (Electrical Discharge Machining) and CNC (Computer Numerical Control) milling, to achieve exact specifications.

- Material Selection and Processing

– Description: Select suitable materials, such as tool steel, and process them to ensure the mold’s durability and performance under high-pressure conditions.

- Mold Assembly

– Description: Assemble the mold components with precision, ensuring all parts fit correctly to handle the stamping operations efficiently and effectively.

- Testing and Prototyping

– Description: Conduct initial tests and produce prototype parts to validate the mold’s functionality and accuracy before commencing full-scale production.

- Production Run

– Description: Utilize the mold in a metal stamping press to produce parts at scale, continuously monitoring to maintain high quality and precision throughout the production process.

- Quality Control and Inspection

– Description: Inspect stamped parts rigorously to ensure they meet specifications and quality standards, including dimensional checks and performance tests.

- Maintenance and Optimization

– Description: Perform regular maintenance on the mold to ensure consistent performance, making necessary adjustments to optimize production efficiency and extend mold life.

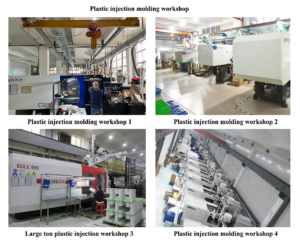

Factory Overview:

Our factory is equipped with state-of-the-art machinery to ensure superior quality. We utilize advanced CNC machines, Mirror EDM, EDM, and Slow-Speed Wire Cut WC for precise mold-making. Our production capabilities include 15 rubber compression molding machines and 2 LSR injection machines. We maintain rigorous quality control with 3D projectors and durometers. Additionally, our facilities feature an AutoDryer Line, automatic screen printing, high-speed doming machines, and CNC machines. This combination of cutting-edge technology and strict quality measures guarantees that we deliver products of the highest standard.