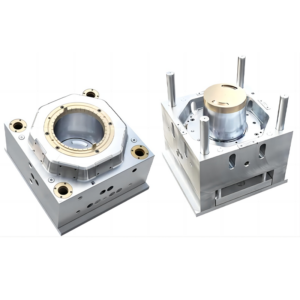

China Durable Water Plastic Bucket Mold

Key Specifications:

Shaping Mode: Injection Mould

Mould Cavity: Multi Cavity

Plastic Material: PE

Runner System: Hot Runner

Design Software: Pro-E

Certifications: TS16949, CE, ISO

Customization: Available

Advantages of Our Mold:

1. Superior Quality:

– Our molds are manufactured using high-grade materials and state-of-the-art techniques, ensuring exceptional durability, precision, and longevity. Each mold undergoes rigorous quality control checks to meet stringent industry standards.

2. Customization:

– We offer highly customizable mold designs tailored to meet specific client requirements. Our team works closely with clients to develop molds that align perfectly with their unique production needs and specifications.

3. Advanced Technology:

– Utilizing the latest in CNC machining, laser cutting, and precision engineering, our molds are crafted with unparalleled accuracy. Our advanced technology ensures consistent, high-quality output and reduces production downtime.

4. Rapid Prototyping:

– We provide quick turnaround times for prototypes, allowing clients to test and validate their designs swiftly. This accelerates the product development process and brings products to market faster.

5. Cost-Effective Solutions:

– By optimizing our production processes and utilizing efficient manufacturing techniques, we offer cost-effective mold solutions without compromising on quality. Our competitive pricing ensures value for money for our clients.

6. Eco-Friendly Materials:

– We prioritize the use of eco-friendly materials and sustainable manufacturing practices. Our commitment to environmental responsibility ensures that our molds have a minimal impact on the environment.

Mold Manufacturing Process:

- Product and Mold Design: Initial design phase where the product and mold are conceptualized and planned.

- Packaging: Preparation and packaging of components for the manufacturing process.

- Steel Preparation: Selection and preparation of steel for mold creation.

- Mold Testing: Conducting trials to ensure mold functionality and accuracy.

- Deep Hole Drilling: Precision drilling to create deep holes required in the mold structure.

- Assembly: Putting together various mold components.

- CNC Machining: Utilizing CNC machines for precise cutting and shaping of mold parts.

- Polishing: Final polishing to ensure a smooth finish and proper functionality of the mold.