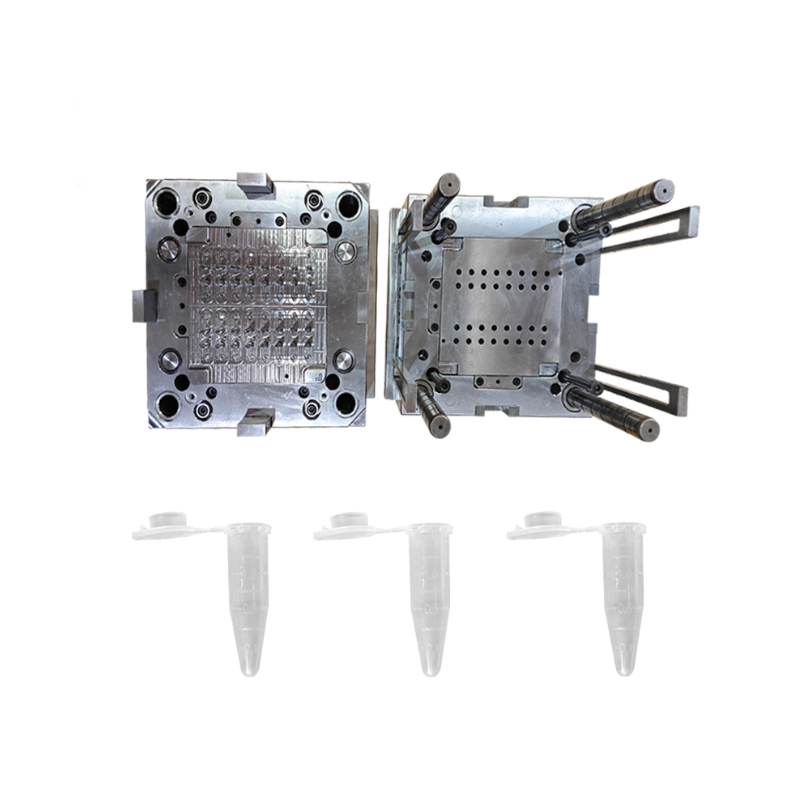

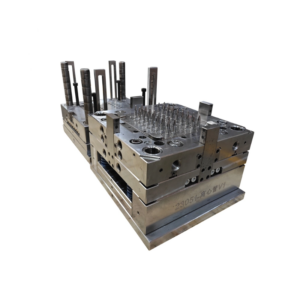

China Factory 32-Cavity Medical Device Mold for Blood Test Tubes

Features:

| Parameter | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM/ODM |

| Model Number | Provide drawings for quote |

| Product Material | Steel |

| Product | Household Appliance |

| Drawing Format Required | IGES, STEP, AutoCAD, Solidworks, STL, DWG, PDF, etc. |

| Mold Standard | LKM, HASCO, DME or as per customer’s requirement |

| Tolerance | +/-0.01~0.05mm |

| Process of Mold | CNC + EDM + Wire Cut + Assembling |

| Mold Material | NAK80, P20, H13, 718, S136, 1.2738, etc. |

| Mold Cavity | Single or Multiple Cavities |

| Mold Life | 50,000 to 1,000,000 shots |

| Production Material | Plastic resin |

| Packaging | Wooden case or Pallets |

| Export Country | Worldwide |

Customization Service for Our Molds:

– Design Consultation: Collaborate closely with clients to understand their specific design requirements and preferences.

– Technical Drawings: Create precise technical drawings and detailed specifications based on client input.

– Material Selection: Provide guidance in selecting appropriate materials for both the mold and the final product to ensure optimal performance and longevity.

– Tooling Development: Develop custom tooling and molds tailored to exact specifications and production needs.

– Prototype Production: Produce prototypes to validate design, functionality, and material choices before commencing full-scale production.

– Mold Fabrication: Employ advanced manufacturing techniques to fabricate high-quality, durable molds.

– Surface Finishing: Apply various surface treatments, including polishing, coating, and texturing, to meet both aesthetic and functional requirements.

– Testing and Validation: Conduct rigorous testing to ensure molds meet all quality standards and performance expectations.

– Adjustments and Iterations: Make necessary adjustments and refinements based on prototype testing and client feedback.

– Production Support: Offer ongoing support throughout the production process, including troubleshooting and maintenance.

– Quality Assurance: Implement stringent quality control measures to ensure molds meet industry standards and client specifications.

– Delivery and Installation: Manage logistics for timely delivery and provide installation support to ensure seamless integration into the production line.

Production Process:

- Design for Manufacturability (DFM) Report:

– Develop a comprehensive DFM report that evaluates the design’s feasibility and identifies potential manufacturing challenges. This includes assessing the product design for optimal moldability and cost-effectiveness.

- Mold Design:

– Create detailed and precise mold designs using advanced CAD software. This step involves defining mold geometry, cavity layout, and essential features based on the product specifications and requirements.

- Material Selection:

– Choose high-quality materials for mold construction, such as steel alloys or specialized polymers, based on the requirements of the product and the intended application.

- CNC Machining:

– Utilize CNC (Computer Numerical Control) machines to precisely cut and shape mold components. CNC machining ensures high accuracy and consistency in mold parts production.

- Laser Cutting:

– Employ laser cutting technology for intricate and detailed cuts in mold components. This process provides high precision and clean edges, essential for complex mold designs.

- Wire Cutting:

– Use Wire EDM (Electrical Discharge Machining) to cut intricate details and complex shapes in the mold components. Wire cutting is critical for achieving high precision and fine tolerances.

- Grinding:

– Perform grinding to refine mold surfaces and ensure smooth finishes. This process enhances the accuracy of mold components and removes any residual machining marks.

- Mold Assembly:

– Assemble all mold components, including cavities, cores, and inserts, into a complete mold structure. This step involves fitting parts together with precision to ensure proper functionality.

- Stamping:

– Apply stamping processes to create specific features or impressions on the mold. Stamping is used for adding logos, text, or other surface details as required.

- Sample Inspection:

– Conduct thorough inspections of sample molds to verify that they meet design specifications and quality standards. This includes testing for functionality, accuracy, and overall performance.

– Conduct thorough inspections of sample molds to verify that they meet design specifications and quality standards. This includes testing for functionality, accuracy, and overall performance.

- Mass Production:

– Once the sample mold is approved, initiate mass production. This phase involves producing molds in large quantities, ensuring consistency and quality across all units.

- Cleaning:

– Clean molds thoroughly to remove any residual debris or contaminants from the manufacturing process. Proper cleaning is essential to maintain mold quality and ensure optimal performance

- Packing:

– Package the completed molds securely to prevent damage during transportation. Packaging includes protective materials and labeling to ensure safe and accurate delivery.

- Delivery:

– Coordinate the delivery of molds to the client’s location. This step involves logistics management to ensure timely and secure transportation of the molds.

- After-Sales Service:

– Provide comprehensive after-sales support, including maintenance, troubleshooting, and any necessary adjustments. This ensures that molds continue to perform well and meet client expectations over time.

![]()