Quality Assurance & Service:

– Lifetime After-Sales Support: We offer lifetime sales-after service for all injection molds, ensuring your complete satisfaction.

– Quick Response: Our team guarantees a 24-hour response time to address all your questions and comments promptly.

– Steel Quality Warranty: Our mold steel comes with a lifetime quality warranty. For 40HRC steel, we offer a 100K shots warranty, and for 45HRC steel, a 1000K shots warranty.

– Precision Manufacturing: All products are CNC machined and prototyped according to drawings. We conduct a 100% size check before shipment to ensure accuracy.

– Comprehensive Documentation: Our engineering team provides material certification, dimension reports, design checklists, and complete mold shipment details for your peace of mind.

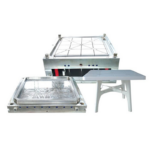

Customization Service for Molds

– Design Consultation:Collaborate with clients to understand specific design requirements and preferences.

– Technical Drawings:Create detailed technical drawings and specifications based on client input.

– Material Selection:Assist in choosing appropriate materials for both the mold and the final product to ensure optimal performance.

– Tooling Development:Develop custom tooling and molds tailored to meet precise specifications and production needs.

– Prototype Production:Produce prototypes to validate design, functionality, and material choices before full-scale production.

– Mold Fabrication:Utilize advanced manufacturing techniques to create high-quality, durable molds.

– Surface Finishing:Apply various surface treatments, including polishing, coating, and texturing, to meet aesthetic and functional requirements.

– Testing and Validation:Conduct rigorous testing of molds to ensure they meet quality standards and performance expectations.

– Adjustments and Iterations: Make necessary adjustments and refinements based on prototype testing and client feedback.

– Production Support:Provide ongoing support throughout the production process, including troubleshooting and maintenance.

– Quality Assurance: Implement stringent quality control measures to ensure the molds meet industry standards and client specifications.

– Delivery and Installation:Manage logistics for timely delivery and offer installation support to ensure seamless integration into the production line.

Our Injection Factory Capabilities

Our factory, established in 2008, is equipped with 15 injection machines of varying sizes, with the largest being 1228 tons. This allows us to produce plastic parts with dimensions up to 1.5m by 1.2m. Our facility is capable of handling a diverse range of products, from sanitary parts to sports equipment, electronics, and automotive components. We also cater to custom requirements, including plastic containers and other specialized items.