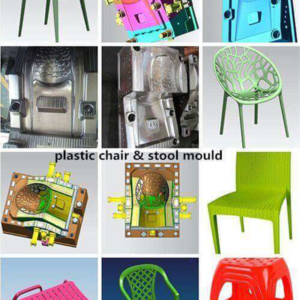

China Plastic Child Care Center Chair Table Mold

Product Description

Product Name: Tableware Mould

Product material: PP

Plastic Tableware Mould cavity: 1cavity

Plastic Tableware Mould material: P20, 718

Plastic Tableware Mould life: 800k shots

Runner system: Hot runner

Ejection system: Gas ejector

Plastic Tableware Mould features: Good quality

Injection cycle time: 30seconds

Tooling time: 35days

Customization Service for Molds

– Design Consultation:Collaborate with clients to understand specific design requirements and preferences.

– Technical Drawings:Create detailed technical drawings and specifications based on client input.

– Material Selection:Assist in choosing appropriate materials for both the mold and the final product to ensure optimal performance.

– Tooling Development:Develop custom tooling and molds tailored to meet precise specifications and production needs.

– Prototype Production:Produce prototypes to validate design, functionality, and material choices before full-scale production.

– Mold Fabrication:Utilize advanced manufacturing techniques to create high-quality, durable molds.

– Surface Finishing:Apply various surface treatments, including polishing, coating, and texturing, to meet aesthetic and functional requirements.

– Testing and Validation:Conduct rigorous testing of molds to ensure they meet quality standards and performance expectations.

– Adjustments and Iterations: Make necessary adjustments and refinements based on prototype testing and client feedback.

– Production Support:Provide ongoing support throughout the production process, including troubleshooting and maintenance.

– Quality Assurance: Implement stringent quality control measures to ensure the molds meet industry standards and client specifications.

– Delivery and Installation:Manage logistics for timely delivery and offer installation support to ensure seamless integration into the production line.

Factory Show:

We operate with advanced machinery and equipment to ensure top-notch quality. Our facilities feature CNC machines, Mirror EDM, EDM, and Slow-Speed Wire Cut WC for precise mold-making. Production is supported by 15 rubber compression molding machines, 2 LSR injection machines, and quality control tools such as 3D projectors and durometers. Our setup also includes an AutoDryer Line, automatic screen printing, high-speed doming machines, and CNC machines. This combination of cutting-edge technology and rigorous quality control ensures we deliver products of the highest standard.