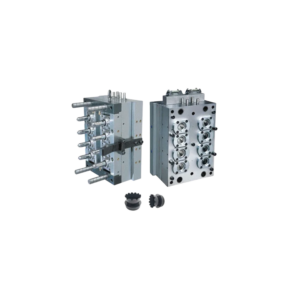

Chinese ABS Injection Molding for Professional Plastic Parts

Features:

| Category | Details |

| Description | OEM/ODM Plastic Injection Molding |

| Plastic Materials | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO, etc. |

| Standard | ISO9001:2008 |

| Quality | RoHS and SGS standards |

| Features | Non-marking and non-flash properties |

| Size | According to your 2D or 3D drawings |

| Color, Quantity, Unit Price, Tooling Cost, Tooling Size | To be discussed |

| Package | Standard exported wooden box packed, fumigation process (upon request) |

| Mold Building Lead Time | 20-30 working days, part measurement report (upon request) |

| Export Countries | Europe, Japan, America, Australia, UK, Canada, France, Germany, Italy, etc. (To be discussed) |

| Specialties | In-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K Mould, Die-Casting Mould, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold Runner System, Hot Runner System Mold, etc. |

| Mould Base | Hasco Standard, European Standard, World Standard, DEM Standard, HUSKY Standard, etc. |

| Mould Base Material | LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement |

| Surface Finish | Texture (MT Standard), High gloss polishing, mirror polishing |

| Cavity/Core Steel | P20, 2311, H13, 2344, Starvax 420, 236, 738H, S136, 2312, 2379, 2316, 2083, Nak80, 2767, etc. |

| Mould Life | 250,000 to 1,000,000 shots (according to your working environment) |

| Design & Program Software | CAD, CAM, CAE, Pro-E, UG, SolidWorks, Moldflow, CATIA, etc. |

| Equipment | High-speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available. |

Exquisite Craftsmanship:

Our products undergo meticulous craftsmanship, utilizing advanced CNC machining, precision drilling, milling, and cutting processes.

High-Quality Materials:

Crafted from lightweight materials with excellent mechanical strength, our products boast exceptional durability, minimal wear, and superior corrosion resistance.

Prototype Adjustment Guarantee:

Should the initial sample fail to meet your expectations, we ensure comprehensive mold modifications until your specifications are fully satisfied.

Our Advantages:

- Comprehensive Service

– Complete one-stop service

– Engineering team from sample to final map development

- Strong Manufacturing Facility

– Robust factory strength

– Extensive OEM/ODM customization capabilities

- Process Customization

– Tailored processing solutions

– Customized mold development

- Stringent Quality Control

– Rigorous quality assurance

– Dedicated mold customization

- Responsive After-Sales Support

– Efficient after-sales service

For any new inquiries, please send us your design files in 3D formats such as STP, IGS, or STL. Additionally, include details about the part material, desired quantity, and any specific surface finish requirements. You can reach out to us via email for a quotation.