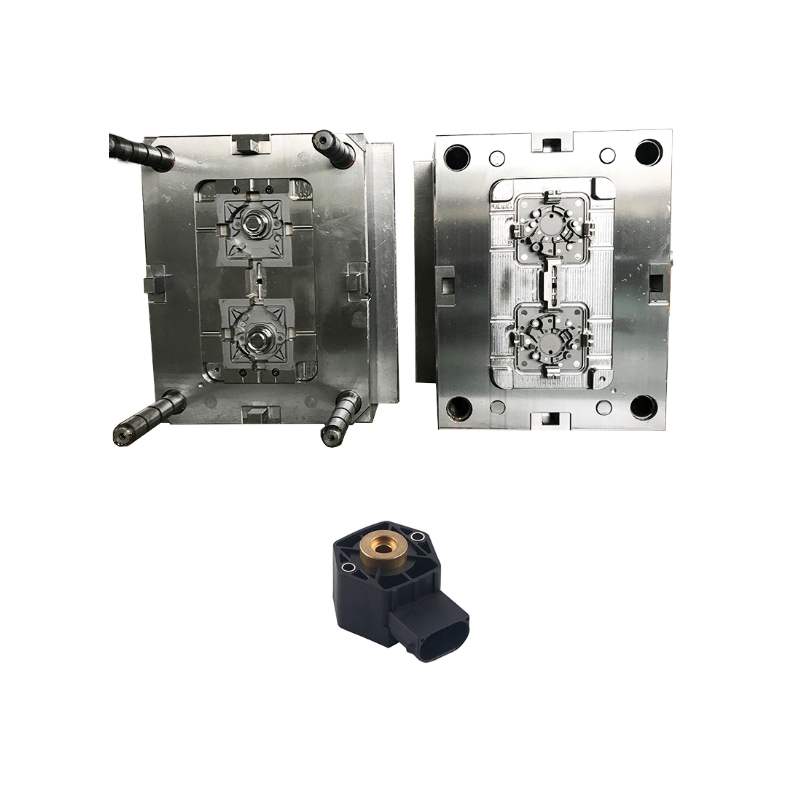

Chinese Manufacture High-Quality Overmolding Mold for ABS PC Case

Overview:

“High-Quality Overmolding Mold for ABS PC Case” is a specialized tool used in manufacturing processes that seamlessly combines ABS (Acrylonitrile Butadiene Styrene) and PC (Polycarbonate) materials through overmolding. This advanced technique involves injecting molten plastic into a mold already containing a preformed part made from another material. The outcome is a single, integrated piece that enhances product strength, durability, and design flexibility.

Features:

| Detail | Item |

| Mould Material | P20, 718, NAK80, S316H |

| Hardness of Steel | Vacuum quenching, nitride, HRC41-47, HRC46-50, HRC60 |

| Mould Base | LKM, HASCO |

| Mould Cavity | Single / Multi |

| Runner System | Hot / Cold |

| Injection Machines | According to product precision: 100T, 128T, 150T, 200T, 250T, 368T, 450T |

| Inspection | 100% inspection by QC, QA before shipping |

| Fast Mould Design | 1-3 working days after receiving customer’s drawings |

| Lead Time | Plastic Moulds: 3-6 weeks after mould design confirmation |

| Mould Testing | All moulds undergo thorough testing before shipment; trial running videos available |

| Minimum Order | Small orders for injection moulding accepted |

| Production Capacity | 50 sets/month |

| CAD for Quote | STEP & DWG |

| Mould Life | 100-500K shots |

| After Sales Service | Available from staff with over 10 years of experience in the field |

Other Features:

– Sample: Comprehensive Overview

– Product Name: Full Customization Injection Mold

– Machine: 80T-600T, 21 Injection Machines

– Business Type: OEM/ODM Customization

– Mold Life: 1,000,000+ Shots/Customization Welcome

– Surface Finish: Polishing, Silk Screening, Texture, Sandblasting, UV Painting, etc.

– Assembly: Available

– Free Samples Available: Yes

Order Process:

- Request for Quotation (RFQ)

- Design for Manufacturability (DFM) & Quotation

- Purchase Order (PO) Placement

- Solution Discussion and Selection

- 2D Layout & 3D Drawing Creation

- Drawing Approval Process

- Selection and Procurement of Mould Steel Material

- Initiation of Mass Production

- Parts Approval and Quality Assurance

- Mould Correction and Iteration

- Customer Feedback Collection

- Delivery of T1 Samples with Inspection Report to Customer

- Mold Trial, Performance Evaluation, and Iterative Improvement

- Mould Machining, Fitting, and Texturing

FAQS:

- Are you a manufacturer or a trading company?

We are a dedicated OEM/ODM manufacturer with over 150 skilled employees. Our services span from mold design and fabrication to plastic injection molding, secondary processing, assembly, shipping, and comprehensive after-sales support.

- How can I obtain an accurate price?

Please provide us with 3D/2D drawings (IGS, IGES, X_T, STP, STEP) for quoting purposes. In the absence of drawings, product pictures with dimensions or samples are acceptable. We also offer Reverse Engineering Services to assist.

- How many samples do you provide?

Typically, we offer 2 sets of 12 shots each for sampling purposes.

- Who should I contact?

Feel free to reach out to us at any time to initiate your custom injection mold project. We are always available and ready to assist you.