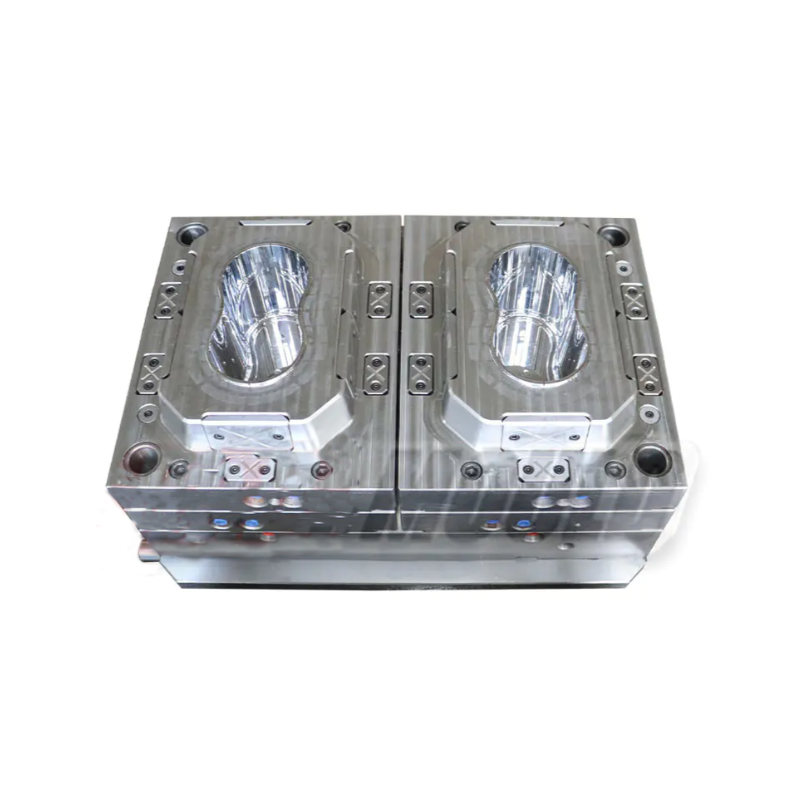

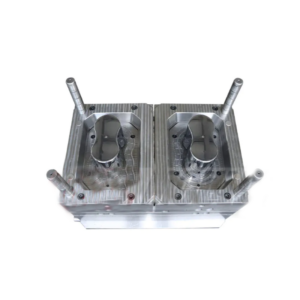

Chinese Manufacture Premium Kitchen Container Mould

Characteristics:

| Mold Name | Plastic Material | Mold Cavity/Core Steel | Runner/Gate System | Manufacture Time (Days) | Mold Life | Machine Size | Demolding |

| Kitchen Container Mould | PPCO | 718H | Hot Runner | 40 | 500,000 shots | 285 Ton | Full Automatic |

With over two decades of expertise in crafting water scoop molds, our company ensures impeccable after-sales support, alleviating any concerns. We invite you to reach out to us for all your industrial mold inquiries.

Mold Packaging Procedure:

- External Packaging: Standard export-grade wooden case.

- Internal Packaging: We apply anti-corrosive oil to the mold surface and cover it with plastic waterproof film.

- Spare Parts Included: Supplementary parts are shipped alongside the mold for convenience.

Our Advantages:

- Comprehensive Processing Facilities:

Equipped with state-of-the-art processing equipment to ensure efficient and precise mold manufacturing.

- Expert Designers and Engineers:

Our team comprises experienced mold designers and engineers who deliver innovative and functional designs.

- Superior Mould Strength:

Utilizing high-quality materials and advanced techniques to create molds with exceptional durability and resilience.

- Optimal Cooling Solutions:

Implementing the best cooling methods to enhance mold performance and productivity.

- Exceptional Polishing Techniques:

Employing advanced polishing techniques to achieve impeccable surface finishes on molds.

- Dedicated After-Sales Support:

Offering outstanding after-sales service to address any issues and ensure customer satisfaction.

- Effective Communication:

Maintaining clear and open communication channels to understand and meet customer requirements effectively.

- Prompt Delivery:

Committed to delivering molds within agreed timelines to meet project deadlines.

- Competitive Pricing:

Providing competitive pricing without compromising on quality, ensuring cost-effectiveness for our clients.