Compression molding tooling refers to the specialized equipment used in the compression molding process, a widely used manufacturing technique for creating plastic, rubber, and composite parts. The process involves placing a pre-measured amount of material into a heated mold cavity, then applying pressure to shape and cure the material into the desired form. Compression molding tooling includes the mold itself, which consists of two main halves: the cavity and the core. These molds are precisely engineered to produce high-quality, repeatable parts with tight tolerances.

The tooling is designed to withstand the high temperatures and pressures involved in the process while ensuring efficient material flow and uniform curing. Depending on the complexity and scale of the product, molds can be made from various materials, such as steel, aluminum, or alloys, chosen for their durability and heat resistance. Compression molding tooling is used for a wide range of industries, including automotive, medical devices, electrical, and consumer products. With its ability to produce strong, lightweight parts in large volumes, it is a key component in manufacturing cost-effective, high-performance products.

Basic Information

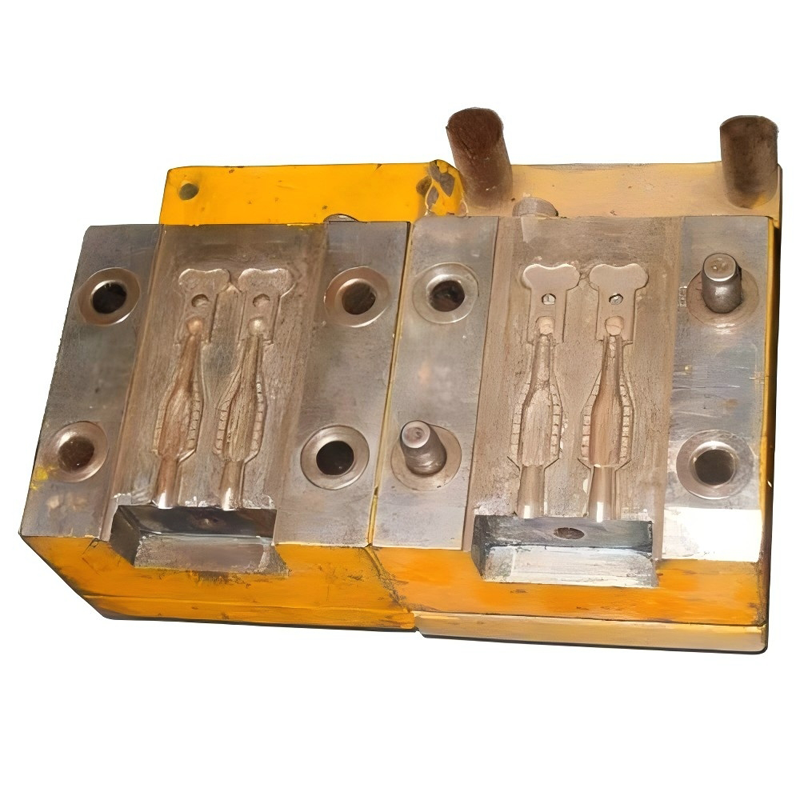

Mold Type: Plastic Injection Mold

Mold Material Options:P20, 718, 738, NAK80, S136

Mold Base Standards: HASCO, DME, MISUMI, JIS, LKM, etc.

Mold Runner System:Cold Runner / Hot Runner

Mold Gate Options:Slide Gate, Sub Gate, Pin-point Gate

Cavity:Single or Multi-Cavity

Design Software Supported:UG, PROE, CAD, SOLIDWORKS

Molding Equipment Used:CNC, Wire Cutting, Milling Machine, EDM

Compatible Raw Materials:Silicone,Rubber

Packaging Method:Wooden pallet or carton

OEM Services:Available—please provide 2D/3D files or samples

Lead Time:Approximately 30 days

Customization Service for Tooling

– Design Consultation:Collaborate with clients to understand specific design requirements and preferences.

– Technical Drawings:Create detailed technical drawings and specifications based on client input.

– Material Selection:Assist in choosing appropriate materials for both the mold and the final product to ensure optimal performance.

– Tooling Development:Develop custom tooling and molds tailored to meet precise specifications and production needs.

– Prototype Production:Produce prototypes to validate design, functionality, and material choices before full-scale production.

– Mold Fabrication:Utilize advanced manufacturing techniques to create high-quality, durable molds.

– Surface Finishing:Apply various surface treatments, including polishing, coating, and texturing, to meet aesthetic and functional requirements.

– Testing and Validation:Conduct rigorous testing of molds to ensure they meet quality standards and performance expectations.

– Adjustments and Iterations: Make necessary adjustments and refinements based on prototype testing and client feedback.

– Production Support:Provide ongoing support throughout the production process, including troubleshooting and maintenance.

– Quality Assurance: Implement stringent quality control measures to ensure the molds meet industry standards and client specifications.

– Delivery and Installation:Manage logistics for timely delivery and offer installation support to ensure seamless integration into the production line.