Customer Service Standards

Pre-Sale:

–Thorough Validation: Engage in detailed discussions with customers to confirm product specifications and quantities, ensuring complete accuracy.

–Dedicated Attention: Handle every inquiry with utmost patience, seriousness, and meticulous attention to detail.

–Lead Time Optimization: Efficiently coordinate production schedules and rigorously monitor lead times to meet customer expectations.

–Rigorous Quality Assurance: Perform comprehensive inspections prior to delivery to guarantee product accuracy and quality.

After-Sales:

–Timely Delivery: Ensure prompt delivery arrangements immediately following order confirmation.

–Delivery Confirmation: Verify receipt of goods with customers upon delivery.

–Feedback Engagement: Actively collect customer feedback and continuously strive to enhance service quality.

Factory Overview:

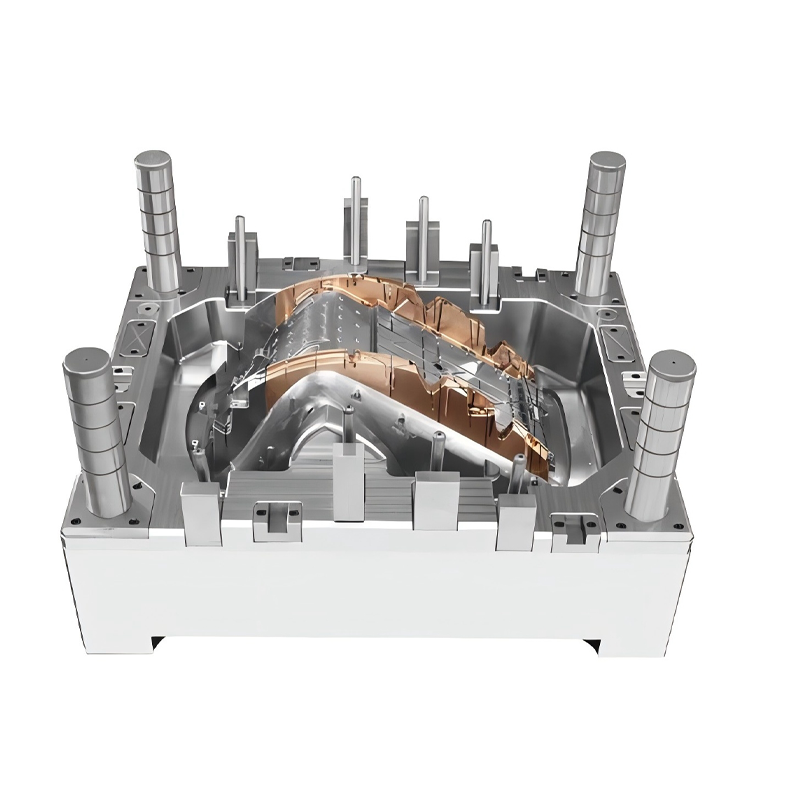

Our facility is equipped with state-of-the-art machinery and technology to ensure superior product quality. We utilize advanced CNC machines, Mirror EDM, EDM, and Slow-Speed Wire Cut WC for precise and efficient mold manufacturing. Our production capabilities are bolstered by 15 rubber compression molding machines and 2 LSR injection machines. To maintain the highest quality standards, we employ sophisticated quality control instruments such as 3D projectors and durometers.

Additionally, our facility is outfitted with an AutoDryer Line, automatic screen printing systems, high-speed doming machines, and CNC machines. This integration of cutting-edge technology and stringent quality control processes enables us to consistently deliver products that meet the highest industry standards.

Mold Manufacturing Process:

- Product and Mold Design: Initial design phase where the product and mold are conceptualized and planned.

- Packaging: Preparation and packaging of components for the manufacturing process.

- Steel Preparation: Selection and preparation of steel for mold creation.

- Mold Testing: Conducting trials to ensure mold functionality and accuracy.

- Deep Hole Drilling: Precision drilling to create deep holes required in the mold structure.

- Assembly: Putting together various mold components.

- CNC Machining: Utilizing CNC machines for precise cutting and shaping of mold parts.

- Polishing: Final polishing to ensure a smooth finish and proper functionality of the mold.