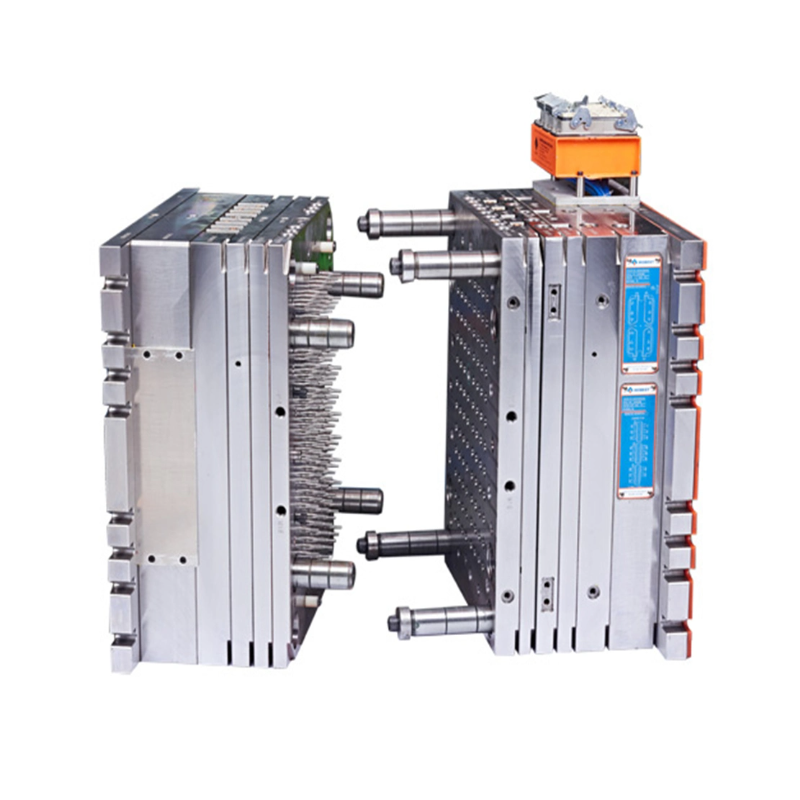

Custom Dual Color Plastic Injection Mold for Electric Drill Handle

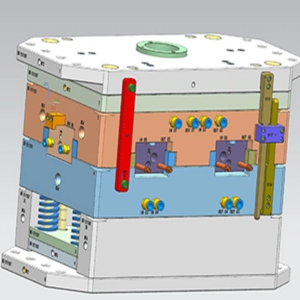

A two-color mold is designed for injection molding where two distinct plastic materials are injected sequentially into the same mold, allowing for a dual-color finished product in a single molding cycle. This type of mold typically consists of two sets of components: one fixed on the injection gate side of the mold machine’s fixed mold plate, and the other on the rotating plate of the moving mold, where the product is ejected.

The lifespan of these molds can be customized to meet specific customer requirements, with capabilities to handle production frequencies up to 1 million molds. Mold tolerance is maintained within an accuracy range of ±0.02mm. Two-color mold processing accommodates sizes ranging from 0.2 to 0.60 meters, catering primarily to small household appliances, electronic peripherals, beauty equipment, maternal and child products, mobile phone casings, power tools, and computer keyboard components.

Features:

| Item | Details |

| Application | Automotive, Household Appliances, Furniture, Consumer Electronics, Hardware |

| Runner | Cold Runner |

| Design Software | AutoCAD |

| Installation | Semi-Fixed |

| Certification | TS16949, CE, ISO, FDA |

| Standard | HASCO |

| Customized | Yes |

| After-sales Service | Lifelong |

| Dimension Tolerance | ±0.005mm |

| Service Life | 0.5-5 Million Cycle Times |

| Lead Time | Approximately 4-6 Weeks, Depending on Design |

| Demould Type | Automatic Ejection |

| Transport Package | Wooden Case |

| Specification | CUSTOMIZED |

| Trademark | OEM |

| Origin | Xiamen, China |

| Production Capacity | 100 sets per Month |

Advantages:

– Efficiency: Achieve high efficiency with shortened delivery times and competitive pricing.

– Customization: Send us your requirements or 2D/3D designs, and we will precisely manufacture spray cap molds and electric meter boxes to meet your exact specifications.

– Comprehensive Services: Toolingsun offers comprehensive services from initial concept to product completion, providing solutions from initial sketches to functional parts.

– Versatility: Our molds can produce a wide range of plastic products.

– Rapid Prototyping: Capable of rapid prototyping to meet quick turnaround needs.

– Reliable Delivery: Ensuring safe and prompt delivery.

– Quality Assurance: Commitment to delivering quantity, superior quality, and competitive pricing.

– OEM Support: Strong support for OEM manufacturing.

– Customer-Centric: We prioritize high-quality service and cater to customer requirements, welcoming custom designs.

– Expertise: Benefit from our extensive experience in mold production design and rigorous management systems.

– After-Sales Support: Dedicated to providing the best after-sales service for customer satisfaction.

Production Workflow:

– Customer Order Confirmation

– Contract Signing

– Project Design

– Project Drawing

– CNC Material Preparation

– Purchase of Main Material Parts

– Integral Grinding

– Wire Cutting

– Coordinate Grinding

– Assembly

– Debugging

– Quality Inspection

– Final Acceptance

– Shipment

– After-sales Service

Rapid Prototyping Services:

– Quotation: Fastest turnaround in 3 minutes.

– Design for Manufacturing (DFM): Provided within 24 hours.

– Tooling Feasibility Check (TFC): Offered within 24 hours.

– Fast Mold Opening and Sample Delivery: Initial sample delivery (T0) within 7 days.

– High Precision Mold Machining: Achieves ±0.005mm accuracy.

– Customer Feedback Response: Prompt response and connectivity within 2 hours.

Factory Overview:

With over 20 years of precision manufacturing experience, our factory excels as an OEM and ODM high-precision manufacturer. We hold certifications in ISO 9001, ISO 14001, and TS16949, ensuring meticulous quality control across all stages from material receipt through production to shipment. Equipped with advanced testing and inspection tools, including imported five-axis equipment and high-precision grinding machines, we operate from a spacious 6000m² production facility.

Backed by a dedicated team, we offer valuable insights and recommendations for customer projects. Our comprehensive service center in France enables swift responses to global customer needs, delivering high-quality, efficient, and intelligent precision products and solutions worldwide.