Plastic Injection Molding in the Medical Industry

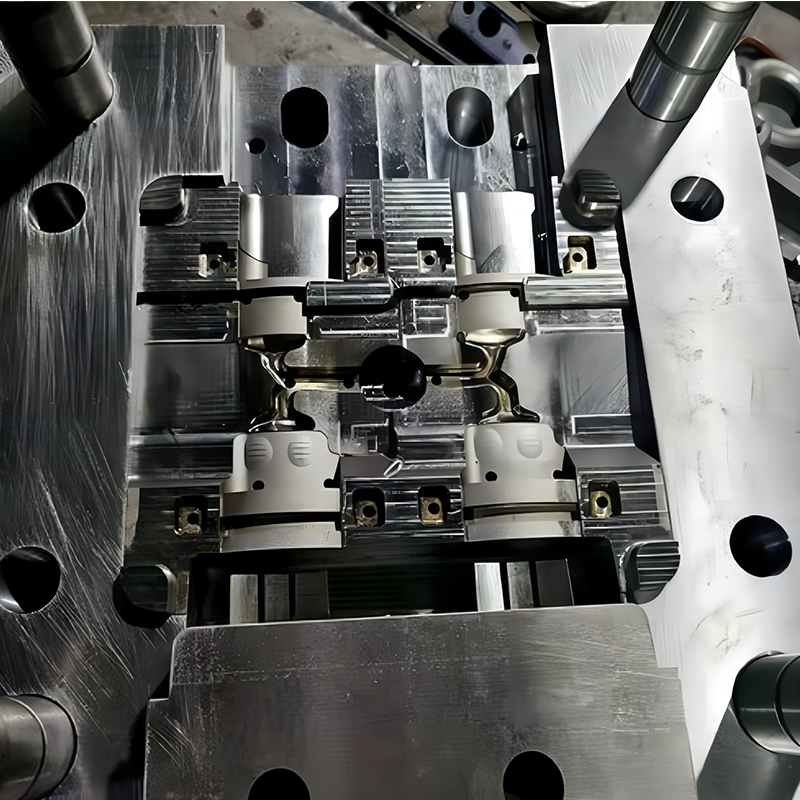

Plastic injection molding is a pivotal process in the medical industry, enabling the creation of complex, high-precision parts and components. This technique involves injecting molten plastic into a precisely engineered mold, which is then cooled and solidified to achieve the desired shape. It is particularly suitable for manufacturing parts with intricate details and complex geometries, making it an ideal choice for medical devices and components.

Expertise in Precision Molding

Our expertise lies in producing highly precise molds, essential for meeting the stringent requirements of the medical industry. With state-of-the-art machinery and a team of seasoned professionals, we focus meticulously on every detail. Our capabilities extend to various domains, including bathroom parts molds, carbon fiber molds, sports equipment molds, and beyond.

Medical Parts Molding Process

The medical parts molding process is designed to create precision components for medical devices. This involves using specialized tools and high-quality materials to ensure that each part meets exact specifications. Injection molding, a key technique in this process, involves injecting molten plastic into a mold to form a desired shape. The resulting parts are not only highly accurate but also boast a longer lifespan compared to those produced by other methods.

Range of Molds Offered

We offer a diverse range of molds to cater to various needs, including but not limited to:

- Soap case molds for shower stands

- Sliding cover molds

- Friction pad molds

- Fastening nut molds

- Marble molds

- Non-slip mat molds

- Decoration ring molding

- Decorative covers for suspension bases

- Sprayer body injection molds

Each mold can be customized based on the customer’s production capacity requirements.

Commitment to Quality and Precision

Our commitment to quality and precision is unwavering. We ensure that every mold we produce adheres to the highest standards, delivering parts that meet the rigorous demands of the medical industry. By focusing on detail and employing advanced technologies, we provide reliable solutions for all your precision molding needs.

For all your custom medical device mold and plastic injection molding requirements, our expertise and dedication to precision ensure that you receive the highest quality products. Whether you need intricate medical parts or related products like soap cases, sliding covers, or decorative components, we have the capabilities to deliver precisely what you need.