Customized Medical Test Tubes Supplying

Our Custom Medical Test Tubes Plastic Injection Molding Mould Factory specializes in creating high-quality, precise components for medical devices and equipment. Utilizing advanced stainless steel medical injection molding, we ensure our products meet the stringent requirements of the medical industry.

Precision Injection Molding with Stainless Steel

Our stainless steel injection molding process involves injecting molten stainless steel into molds to produce complex and intricate parts with tight tolerances. This method is highly durable and resistant to corrosion, making it perfect for medical applications. We offer a range of injection molding types to suit various needs:

- Ordinary Injection Molding

- Double Color Injection Molding

- Over Molding

- Insert Molding

- Liquid Silicone Rubber (LSR) Molding

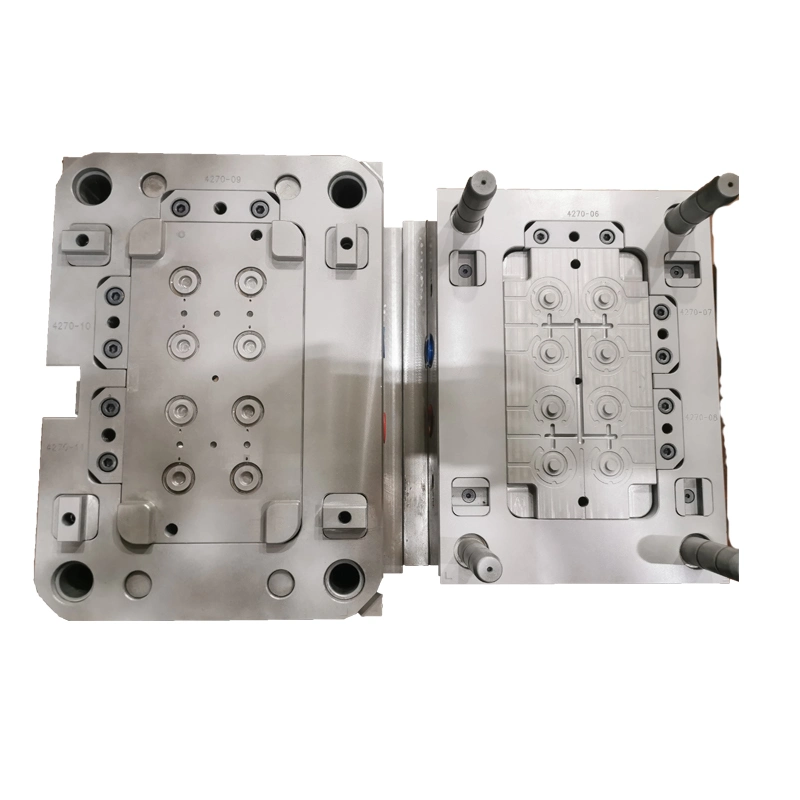

Expertise in Mold Design

Our strong design team can accommodate various input methods, including providing samples, three-dimensional drawings, and two-dimensional drawings. We welcome inquiries and are ready to provide quotations based on your specific requirements.

Manufacturing Capabilities

Our large machine shop is equipped with high-speed and high-precision CNC machines, allowing us to produce both prototype and production molds in-house. Our typical turnaround time for prototype molds is 1-2 weeks, while production molds are completed within 4-6 weeks, depending on design complexity.

Applications for Medical Device Injection Molding

Injection-molded parts for medical devices have a wide range of applications. Our products can be used in:

- Point-of-Care Testing IVD Devices: Creating precise and reliable components for in-vitro diagnostics.

- Microfluidic Cartridge Devices: Manufacturing intricate parts for microfluidic systems.

- Off-Shelf Disposables: Producing everyday medical disposables such as vials and transfer pipettes.

- Medical Wearables: Developing durable and comfortable wearable medical devices.

- Testing Kits: Fabricating various components used in medical testing kits.

Why Choose Us?

- High Precision: Our advanced equipment and experienced team ensure the highest precision in every part we produce.

- Durable Materials: Utilizing stainless steel for its durability and corrosion resistance.

- Quick Turnaround: Fast production times for both prototype and production molds.

- Versatile Applications: Serving a wide range of medical device applications with our injection-molded parts.

For more information or to request a quote, please feel free to contact us. We look forward to assisting you with your medical device manufacturing needs.