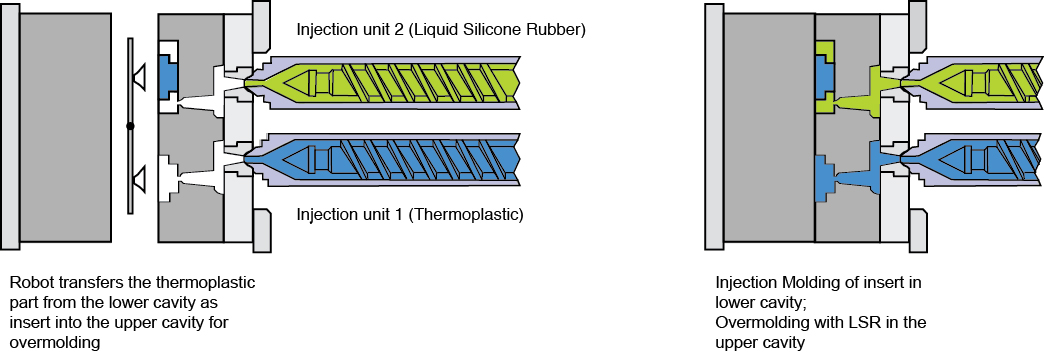

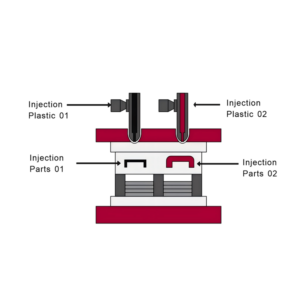

Our plastic 2-shot molding molds are expertly designed to deliver superior quality and precision in multi-material molding processes. Two-shot molding, also known as dual-shot, double-shot, or multi-shot, allows for the combination of two different plastic resins in a single production cycle, enhancing efficiency and product integrity. This advanced molding technique is ideal for creating complex parts with varying textures, colors, or materials. With our commitment to delivering customized solutions, we ensure that every mold is crafted to the highest standards of quality and durability. From initial design to final production, we focus on optimizing performance and reliability, guaranteeing timely delivery, competitive pricing.

Basic Information

Place of Origin:Xiamen, China

Product Material: Steel

Plastic Material :PP, PC, PA, PA6, ABS, PET, PVC, POM, etc.

Gate System :Cold Runner / Hot Runner

Ejection System: Pin / Stripper Plate, etc.

A.B Plate Material: 1.1730 / P20, etc.

Tool Life: Prototype to 1,000,000 shots

Cavity & Core Material :P20 / H13 / NAK80 / S50C / S136 / 738H, etc.

Surface Finish :Polish / Texture / Heat Treatment, etc.

Cavities: Single / Multiple / Family Mold

Lead Time: 3 to 8 weeks

OEM Services for Molds

– Custom Design: Develop bespoke designs based on client specifications, including detailed technical drawings and 3D models.

– Material Selection: Assist clients in choosing the right materials for both the mold and the end product to ensure durability and performance.

– Tooling Development: Design and manufacture custom tooling and molds tailored to specific production needs and technical requirements.

– Prototype Creation: Produce prototypes for client review to verify design accuracy and functionality before proceeding with mass production.

– Precision Machining: Utilize advanced machining techniques, including CNC and EDM, to create high-precision molds.

– Surface Treatment: Apply various surface finishes, such as polishing, coating, and texturing, to meet aesthetic and functional specifications.

– Testing and Validation: Conduct thorough testing of molds to ensure they meet performance standards and client requirements.

– Iterative Refinements: Make necessary adjustments based on testing results and client feedback to optimize mold performance.

– Production Support: Provide ongoing support throughout the production process, including troubleshooting and adjustments.

– Quality Assurance: Implement rigorous quality control procedures to ensure all molds meet industry standards and client specifications.

– Logistics and Delivery: Manage the delivery process to ensure timely and secure shipment of molds to client facilities.

– After-Sales Support: Offer comprehensive after-sales support, including maintenance and modifications, to ensure continued satisfaction and performance.