Customized Plastic Auto Battery Case Mold

Our custom plastic auto battery container injection mold is engineered to deliver exceptional precision and efficiency, suitable for large-scale production. The mold features multiple hot nozzles and specially treated inserts, designed to significantly reduce the injection cycle time and ensure high-quality output.

Mold Specifications

Battery Container Mold

This mold is tailored for manufacturing robust car battery containers:

- Dimensions: 750750580 mm

- Weight: 2352 kg

- Injection Cycle Time: Approximately 45 seconds

- Runner System: Hot runner mold with seven open direct hot nozzles, ensuring consistent material flow and quality.

- Core Insert Material: Made from Beryllium Copper (Becu), this material enhances heat dissipation, thus reducing the cycle time and improving productivity.

- Ejection Method: Utilizes a pushing plate system for smooth and efficient ejection of the final product.

- Cavity Material: Constructed from 1.2344 steel, which undergoes a heat treatment process to enhance durability and lifespan.

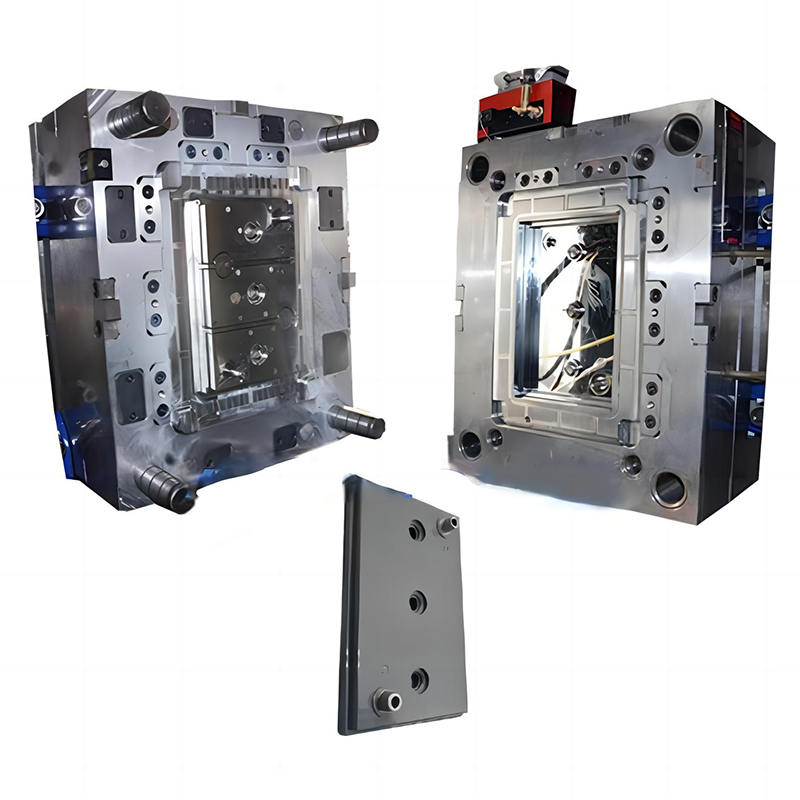

Battery Cover Mold

Designed to complement the battery container mold, this cover mold boasts:

- Dimensions: 550550460 mm

- Weight: 842 kg

- Injection Cycle Time: Approximately 32 seconds

- Materials: Both cavity and core materials are made from heat-treated 1.2344 steel, ensuring durability and consistent performance. The product itself is made from a PC+ABS blend, offering strength and flexibility.

- Rear Mold Inserts: These are inlaid to facilitate easier processing and efficient exhaust management, ensuring high-quality output.

Features and Services

Our company specializes in the development of large-scale injection molds, with a strong focus on automotive, household, and industrial applications. We offer comprehensive services, including the processing of semi-finished mold products. Our molds are designed to meet the highest standards of efficiency and precision.

Product Range

Our expertise extends across various product categories:

- Household Parts Mould

- Appliance Parts Mould

- Automotive Parts Mould

- Thin-wall Parts Mould

- Industry Parts Mould

- Advanced Equipment

We are equipped with state-of-the-art machinery to handle complex and high-precision molding requirements. Our equipment includes:

- Five-axis high-speed milling machines

- Three-axis high-speed milling machines

- CNC milling machines

- Deep hole drilling machines

- Large-scale milling machines

- CNC engraving machines

- Electric sparks (EDM)

- Wire cutters

Commitment to Quality

We are committed to delivering high-quality, precision-engineered molds, driven by technological innovation and a service-oriented approach. Our advanced equipment and skilled team enable us to create molds that meet and exceed industry standards, ensuring customer satisfaction and long-term reliability.