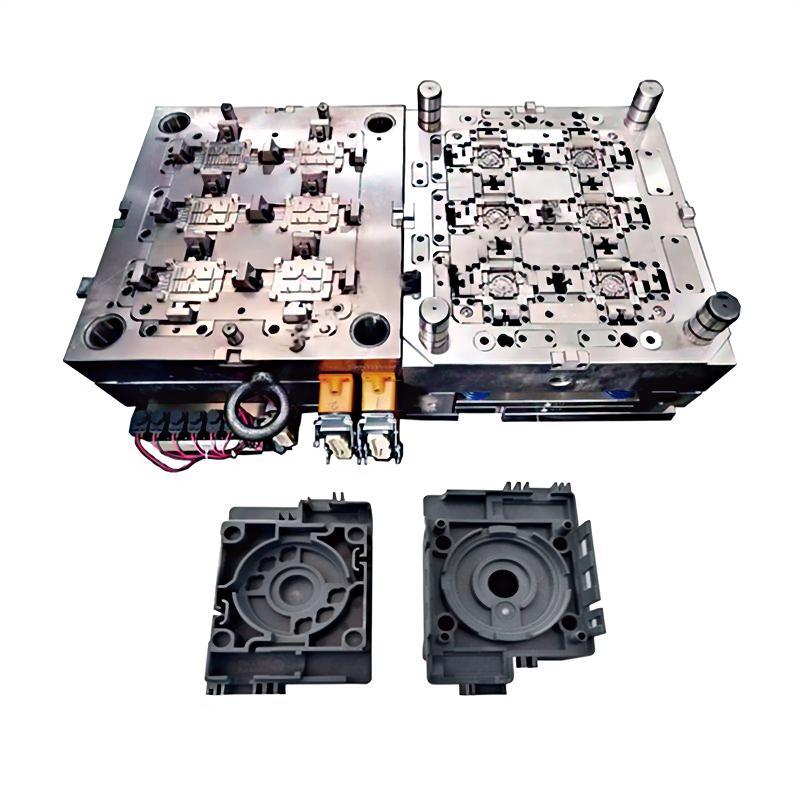

Custom Plastic Electronic Switch Tooling Plastic Injection Mold

Overview

We are delighted to introduce our advanced plastic injection mold tailored for the production of high-precision plastic electrical switch parts. This mold incorporates cutting-edge technology, including six needle valve type hot nozzles, ensuring that every product meets the exact specifications and high standards required.

Detailed Mold Specifications

Mold Dimensions: 500 mm x 500 mm x 480 mm, providing a sturdy framework for injection molding.

Weight: 765 kg, designed to offer stability and durability for consistent, high-quality output.

Cavities: Six, allowing for the production of multiple parts simultaneously, enhancing efficiency and productivity.

Sliders: Twenty-four, enabling complex part geometries and intricate movements essential for precise electrical switch components.

Material of Plastic Products: PA66+GF30, a composite known for its superior strength, rigidity, and thermal stability, making it ideal for electrical components.

Main Mold Material: H13 steel, renowned for its high resistance to thermal and mechanical stress, ensuring a long-lasting mold.

Mold Lifespan: Capable of producing 500,000 to 750,000 shots, making it a cost-effective solution for high-volume production.

Hot Needle Valve Points: Six, ensuring precise control over plastic flow, reducing defects, and enhancing the overall quality of the parts.

Advanced Processing Equipment

Our manufacturing process utilizes state-of-the-art equipment to ensure the highest levels of precision and quality:

High-Speed CNC Machining Centers: For rapid and accurate machining of mold components.

Mirror Discharge Machines: Providing exceptional surface finishes and precision.

Slow Wire Cutting Machines: Ensuring precise dimensions and intricate shapes.

Precision Grinders: Delivering the exact dimensions and surface finishes required for high-quality molds.

Our facility is also equipped with advanced testing equipment to verify the accuracy and quality of every mold produced.

Comprehensive One-Stop Service

We offer a full spectrum of services to meet all your plastic product customization needs:

Mold Design: Our experienced designers collaborate with you to create molds that meet your specific requirements.

Precision Plastic Mold Making: Using advanced techniques and equipment, we ensure our molds deliver consistent, high-quality results.

Custom Plastic Injection Molding: We produce parts that meet your exact design specifications and quality standards.

Assembly Work: Providing complete assembly services for your molded parts.

Pad Printing and Silk Screen Printing: Adding logos, labels, and other graphics to your parts.

Painting: Offering various finishes and colors to your products.

Ultrasonic Welding: For strong and precise joining of plastic parts.

Packaging Services: Ensuring your products are securely and efficiently packaged for delivery.