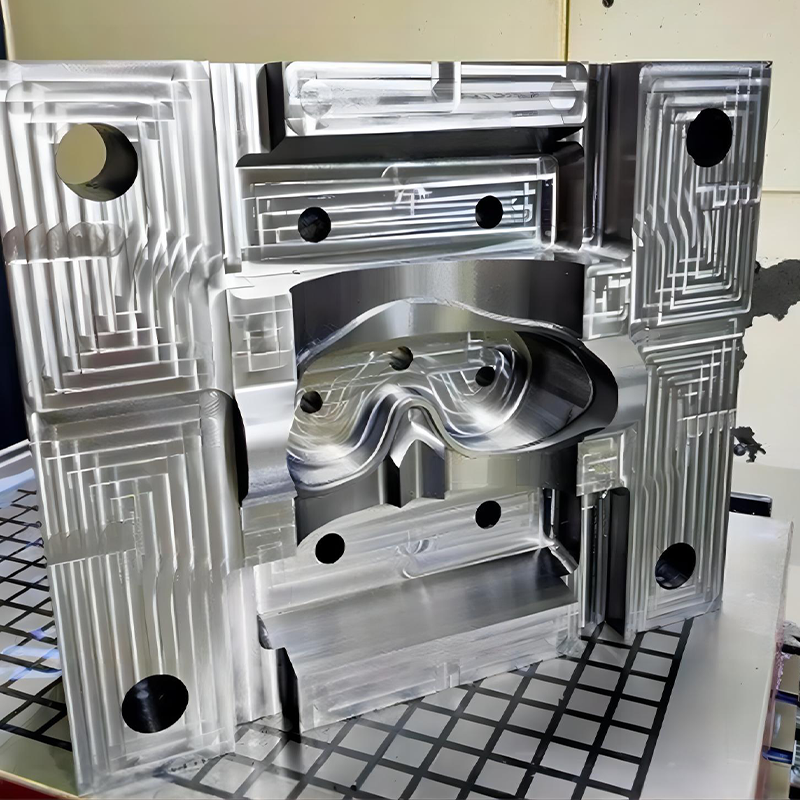

Medical Injection Mold for Plastic Goggles

Plastic goggles are a versatile and widely used product, valued for their lightweight, durable, and protective qualities. They are commonly used in activities such as swimming, skiing, and cycling.

Production Process of Plastic Goggles

Mould Creation

The creation of plastic goggles begins with the design and manufacture of a mould. This mould is typically made from robust materials like metal or high-strength plastic. The mould is carefully crafted to form the precise shape of the goggles. Once designed, the mould is filled with molten plastic.

Mould Heating and Cooling

After the plastic is introduced into the mould, it is subjected to a heating process followed by cooling. This cycle ensures the plastic takes on the desired shape accurately. The precise control of temperature during this stage is crucial to achieve high-quality, defect-free goggles.

Final Product Extraction

Once the plastic has cooled and solidified, the goggles are extracted from the mould. This marks the completion of the manufacturing process, rendering the goggles ready for use.

Importance of the Plastic Goggle Mould

Ensuring Quality and Precision

The plastic goggle mould is a critical component in the production process. It must be meticulously designed and manufactured to ensure the resulting goggles are safe, reliable, and of high quality. The mould must withstand the high temperatures and pressures involved in the injection moulding process.

Versatility in Design

The mould allows for the creation of various styles, shapes, and sizes of goggles. This flexibility enables manufacturers to produce goggles that meet diverse user requirements and preferences. Customization options are vast, ensuring that the goggles can be tailored to fit specific needs.

Customizable Colors

The ability to mix different types of plastics allows for the production of goggles in a wide array of colors. This customization enables users to match their goggles to specific outfits or personal styles, enhancing the appeal of the product.

Maintenance of the Plastic Goggle Mould

To ensure the longevity and reliability of the goggles, it is essential to maintain the mould properly. Regular cleaning and maintenance help preserve the accuracy and efficiency of the mould, guaranteeing that each batch of goggles meets the highest standards of safety and durability.