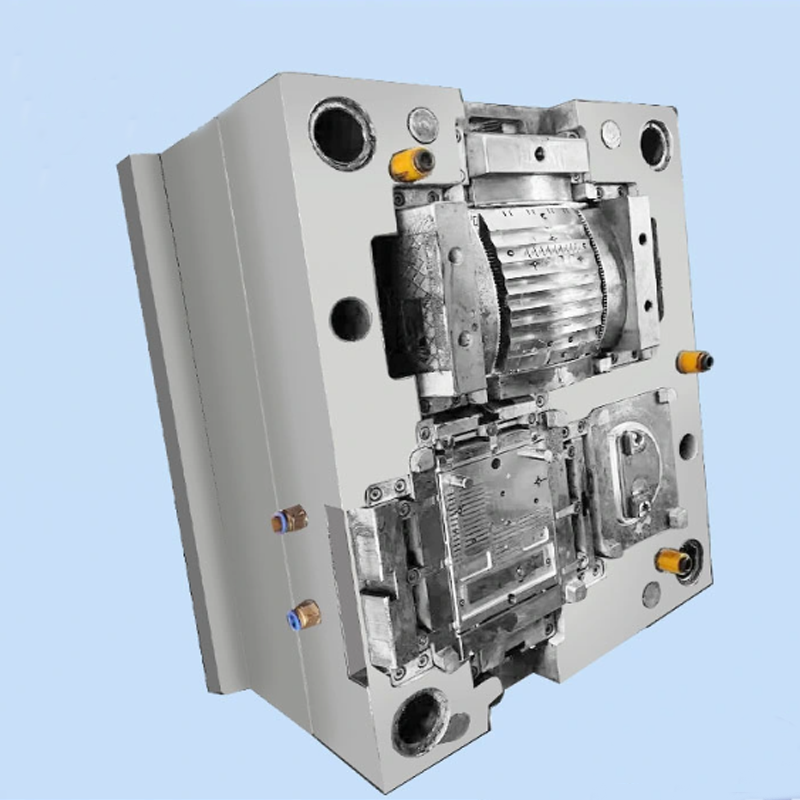

Custom Plastic Injection Mold for Electronic Terminal Block Connector

Details:

| Mould Type | Plastic Injection Mold |

| Mould Material | P20/718/738/NAK80/S136 |

| Mould Base | HASCO, DME, MISUMI, JIS, LKM, etc |

| Mould Runner | Cold Runner/Hot Runner |

| Mould Gate | Slide Gate/Sub Gate/Pin-point Gate |

| Cavity | Single/Multi Cavity |

| Designing Software | UG/PROE/CAD/SOLIDWORKS |

| Moulding Equipment | CNC, Wire Cutting, Milling Machine, EDM |

| Raw Material | ABS, PP, PC, PA6, PA66, PVC, POM, PMMA, PS, etc |

| Package Way | Wooden Pallet, Carton |

| OEM/ODM | Welcome and please offer 2D/3D file or sample |

| Lead Time | About 20 days |

Our Dedicated Team:

Our team comprises highly skilled professionals with extensive expertise in injection mold tooling, design, and automation. We prioritize continuous skill and knowledge development to deliver optimal solutions for our customers, utilizing modern manufacturing methods.

Comprehensive Manufacturing Solutions:

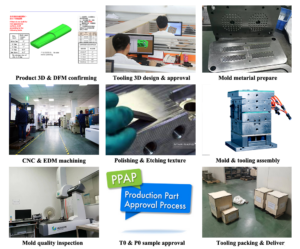

From our advanced facility in Xiamen, China, Toolingsun provides cutting-edge precision engineering technology and a comprehensive array of services for our esteemed clientele. Our offerings include:

- Injection Molding Prototype Design

- Rapid Prototyping

- Mold Tool Design

- Tool Fabrication

- Injection Molding

- Assembly and Secondary Processing

- Ultrasonic Welding

- Painting Services

- Printing Services

Factory Show:

![]()

Protective Tips for custom plastic injection molds:

- Maintain Proper Venting:Ensure adequate venting in the mold to prevent air traps and improve resin flow during injection molding.

- Regular Cleaning and Maintenance:Conduct routine cleaning and maintenance of the mold components to prevent buildup of debris and ensure smooth operation.

- Optimize Cooling System:Properly design and optimize the cooling system to control mold temperature and reduce cycle times, improving productivity and part quality.

- Use High-Quality Materials:Select high-quality mold materials and components to ensure durability and longevity, minimizing wear and tear during production.

- Implement Correct Injection Parameters:Set and monitor appropriate injection parameters such as injection speed, pressure, and temperature to prevent defects like warping, sink marks, and flash.

- Control Moisture Content:Keep resin materials dry and moisture-free to prevent defects like splay and bubbles in the molded parts.

- Regular Inspection and Testing:Perform regular inspections and testing of the mold and molded parts to identify and address any issues promptly, ensuring consistent quality output.

Experience precision injection molding solutions tailored for global brands in supermarkets, cosmetics, and electronics. With over 20 years of expertise, we employ state-of-the-art techniques to manufacture your products with unmatched precision. From initial design to manufacturing, we work closely with you to deliver integrated services using high-quality injection moldings. Explore our comprehensive range of services and contact us for further details. Your satisfaction is our priority.