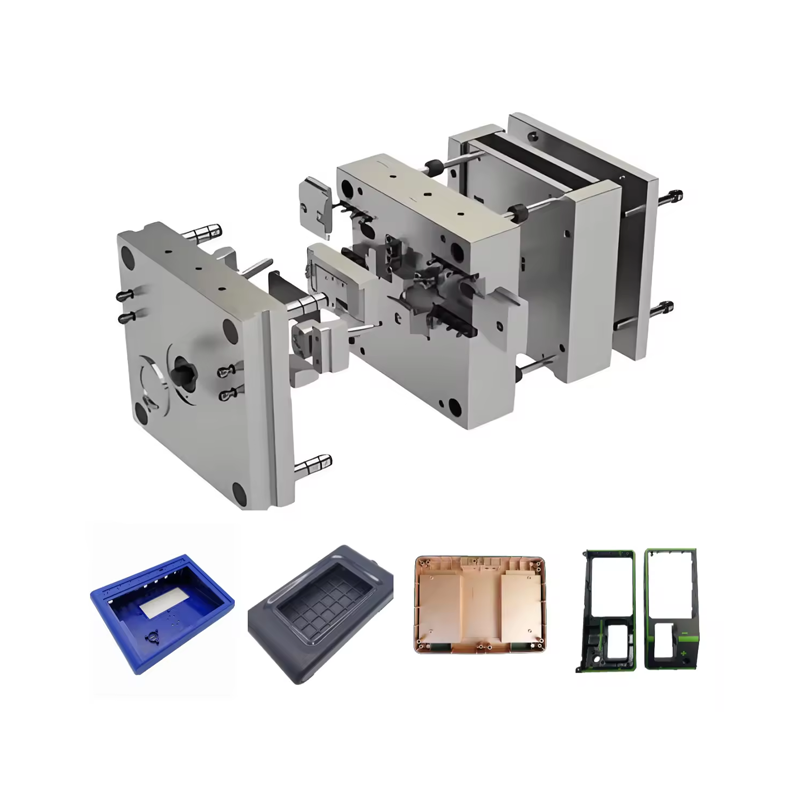

Custom Plastic Injection Molding for Plastic Instrument Electronic Devices

Ensuring Seamless Integration of 3D-Printed Prototypes with Plastic Injection Molding for Plastic Instrument Electronic Devices

We provide expert guidance from a mold manufacturing perspective to ensure that 3D-printed prototypes meet the stringent requirements of final production stages. This involves meticulous consideration of special materials and design factors crucial for mold manufacturing.

Our goal is to streamline the entire manufacturing process, facilitating a seamless transition from 3D printing to mold manufacturing. By enhancing efficiency and implementing cost-effective measures, we guarantee optimal outcomes for your Plastic Instrument Electronic Devices.

Features:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand | OEM/ODM |

| Model Number | OEM |

| Product Material | Plastic |

| Product | Household Product |

| Keyword | Plastic Injection Molding Service and OEM Assembly |

| Description | Custom Plastic Injection Molding Companies Supply Molded Parts |

| Mold Base | LKM, HASCO, DME or upon customer’s requirement |

| Mold Life | 50,000 to 1,000,000 shots |

| Mold Core | 45#, 50#, P20, H13, 718, 1.2344, 1.2738, NAK80, S136 etc |

| Production Material | PP, PC, PS, PA6, POM, PE, PU, PVC, ABS, PMMA etc |

| Mold Cavity | Single or Multiple Cavities |

| Packaging | Polybag packing or packed according to customer requirements |

| Transportation | By sea or by air as per customer requirements |

| Main Export Country | USA, UK, Germany, Switzerland, France, Italy, Australia, Southeast Asia |

Product Packaging Solutions

We specialize in customizing the ideal packaging methods for your finished goods. Our expertise lies in crafting tailored packaging solutions, offering a range of options such as blister packing, art package packing, cotton bag packing, and more.

Our Services Include:

– Product ID & MD Design

– Customized Design of Various Parts

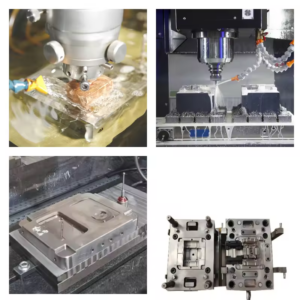

– CNC Machining Parts

– Vacuum Casting Parts

– Small Volume Production

– Mold Design Flow Analysis DFM Report

– Custom Plastic Mold, Hot Compression Mold, and Stamping Molds

– Plastic Injection Molding, Hot Compression, and Stamping Punching Processes

– Finishing Services: Polish, Matte Finish, Spray Painting, Silk Screening, Anodizing, Chrome Plating, and Assembly, etc.

Our Advantages:

– Customized molds and products tailored to your designs, with a quote provided within 24-48 hours.

– Over 20 years of experience in mold and molding production.

– Free analysis of drawings to optimize product structure.

– Complimentary sampling services.

– Comprehensive offerings spanning mold making, injection/rubber molding, silk-screen printing, electroplating, assembly, and more.