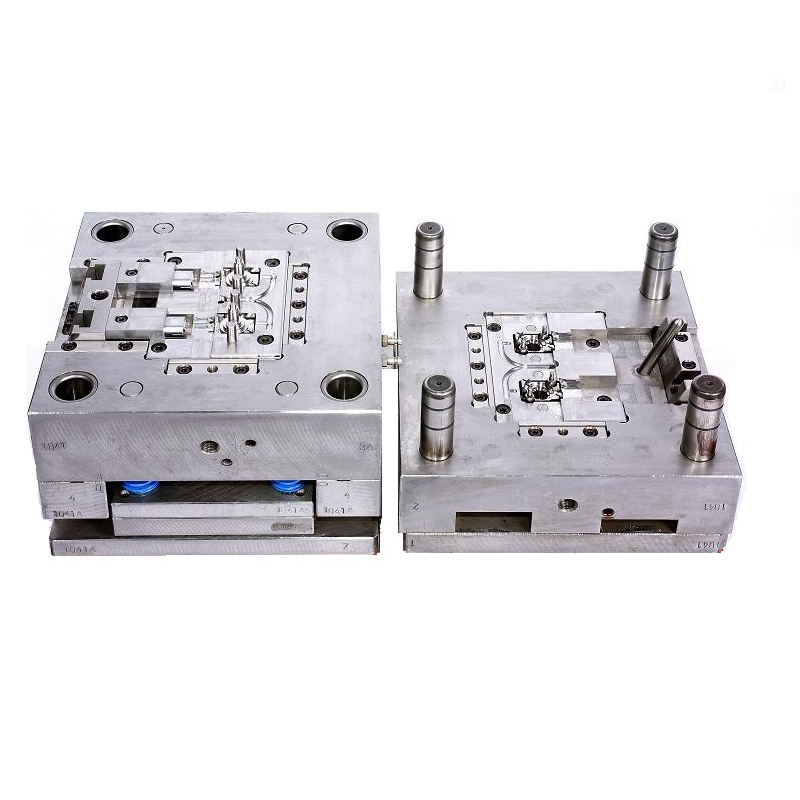

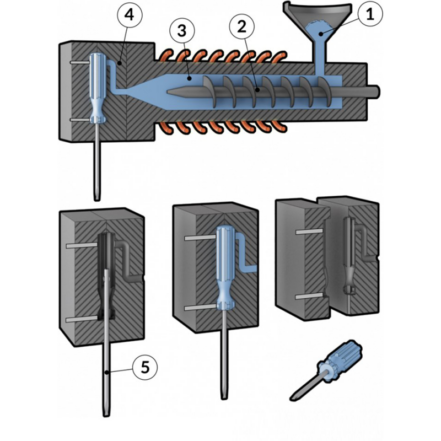

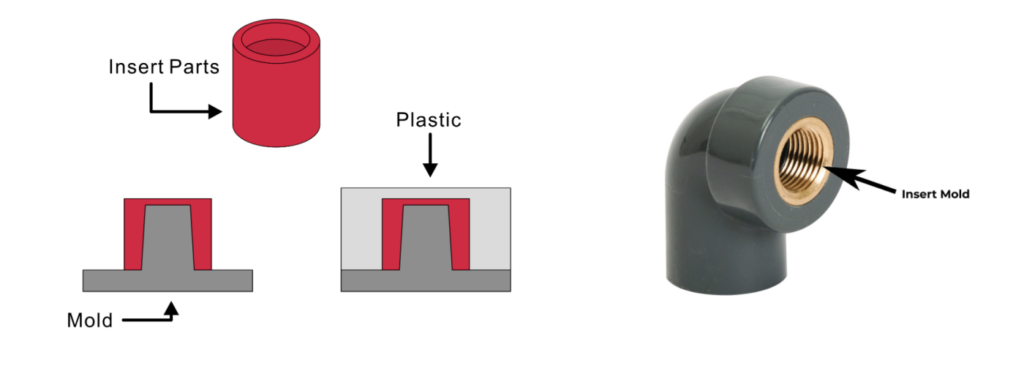

Our plastic insert molding molds are precision-engineered to meet complex manufacturing needs, integrating components for enhanced strength and durability. We provide customized solutions with advanced techniques such as multi-material molding and precision insert placement, ensuring seamless bonding and high performance. Each mold is crafted with attention to detail and optimized for longevity. Our expertise guarantees reliable production, efficiency, and cost-effective solutions tailored to your specific requirements.

Basic Information

Plastic Material: ABS, PP, PC, POM, PMMA, Nylon, TPE, TPU, etc.

Process Combination Type: Single-Process Mode

Application: Automotive, Household Appliances, Electronics, Home Use

Runner System: Hot Runner / Cold Runner

Design Software: UG, PRO-E, AutoCAD

Installation: Fixed

Certification: ISO

Customization: Available (Customized)

Mold Standard: LKM, HASCO, DME, or as per customer requirements

Mold Material: P20, 718, NAK80, S316H

Production Material: ABS, PP, PC, POM, PMMA, Nylon, TPE, TPU, etc.

Hardness: 45-56 HRC

Mold Life: 100K to 500K shots

Lead Time: 3-6 weeks after mold design confirmation

Transport Package: Wooden Box

Specification: As per design

Place of Origin: Xiamen, China

Production Capacity: 50 sets per month

One-Stop Service for Molds

– Initial Consultation: Assess client needs and provide expert advice on design, material selection, and tooling requirements.

– Custom Design: Create tailored designs based on client specifications, utilizing advanced CAD and 3D modeling tools.

– Tooling Fabrication: Manufacture precision molds and tooling using high-quality materials and state-of-the-art machinery.

– Prototype Development: Produce and refine prototypes to validate designs and ensure they meet client expectations.

– Comprehensive Testing: Conduct rigorous testing to verify mold performance, including functionality, durability, and accuracy.

– Surface Finishing: Apply various surface treatments such as polishing, coating, and texturing to achieve desired aesthetics and functionality.

– Production Readiness: Prepare molds for mass production, including final adjustments and quality checks.

– Logistics Management: Handle the complete logistics process, including packaging and shipping to ensure timely and safe delivery.

– Installation Support: Provide guidance and assistance with mold installation and setup to integrate seamlessly into client production lines.

– Quality Assurance: Implement stringent quality control measures throughout the process to ensure all products meet industry standards and client specifications.

– After-Sales Service: Offer ongoing support for maintenance, troubleshooting, and modifications to ensure long-term satisfaction and optimal performance.