Custom Plastic Tire Cover Mould Manufacturer for Automotive Industry

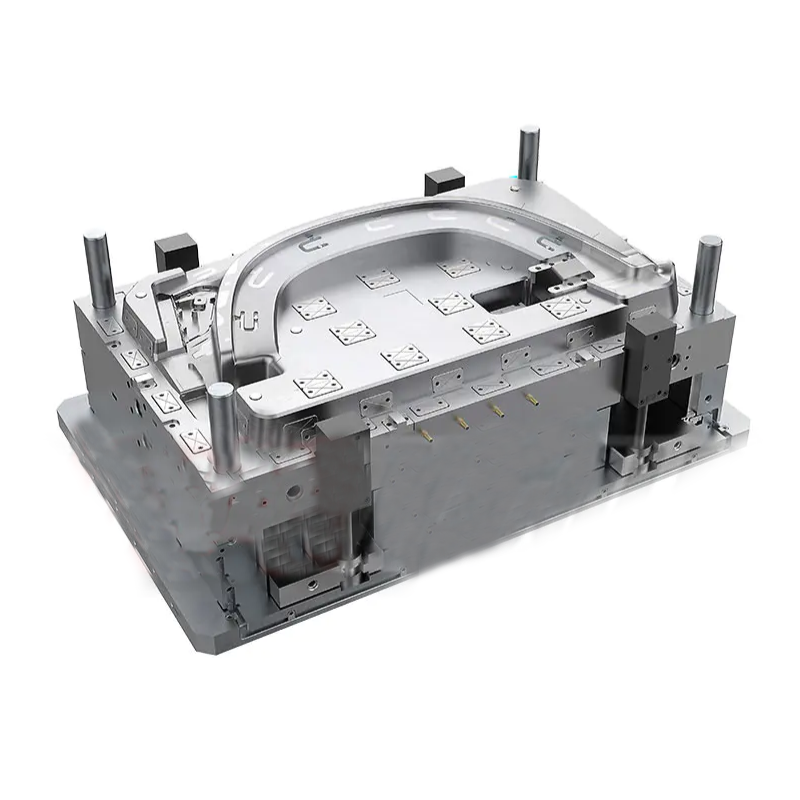

Plastic Tire Cover Mould,featuring standard hardness for cavity and core, utilizing high-quality German steel, and equipped with a high-speed injection and fully automatic ejection system. With years of expertise and cutting-edge equipment, we ensure high-quality products, timely delivery, and competitive pricing for our customers.

Features:

| Feature | Description |

| Product Name | Plastic Tire Cover Mould |

| Plastic Material | PP (Polypropylene) |

| Mold Cavity/Core Steel | 718H |

| Runner/Gate System | Hot Runner |

| Manufacture Time | 40 Days |

| Mold Life | 500,000 shots |

| Machine Size | 330 Ton |

| Demolding | Fully Automatic |

| Mold Dimensions | Customizable based on tire cover specifications |

| Surface Finish | Polished, textured, or as per client requirements |

| Precision | High precision for exact fit and function |

| Customization | Custom designs and specifications available |

| Application | Designed for automotive industry, specifically for tire covers |

| Quality Assurance | Rigorous quality control throughout the manufacturing process |

| Maintenance | Free maintenance for all molds processed in our company |

| Environmental Resistance | Mold designed to withstand various environmental conditions, ensuring durability and longevity |

| Inspection | Comprehensive inspection and testing to ensure mold functionality and product quality |

| Delivery | Secure and timely delivery, with options for express shipping |

| Support | 24/7 customer support and technical assistance available |

Comprehensive Services by Toolingsun:

Toolingsun offers a complete solution from initial concept to finished product, transforming paper sketches into functional parts.

- Versatile molds for various plastic products

- Rapid prototyping capabilities

- Secure and expedited delivery

- High-quality products at competitive prices

- OEM support

- Exceptional service quality

- Welcoming custom designs and meeting customer specifications

- Extensive experience in mold production and design with a rigorous management system

- Outstanding after-sales support

Mold Manufacturing Process:

- Product and Mold Design: Initial design phase where the product and mold are conceptualized and planned.

- Packaging: Preparation and packaging of components for the manufacturing process.

- Steel Preparation: Selection and preparation of steel for mold creation.

- Mold Testing: Conducting trials to ensure mold functionality and accuracy.

- Deep Hole Drilling: Precision drilling to create deep holes required in the mold structure.

- Assembly: Putting together various mold components.

- CNC Machining: Utilizing CNC machines for precise cutting and shaping of mold parts.

- Polishing: Final polishing to ensure a smooth finish and proper functionality of the mold.