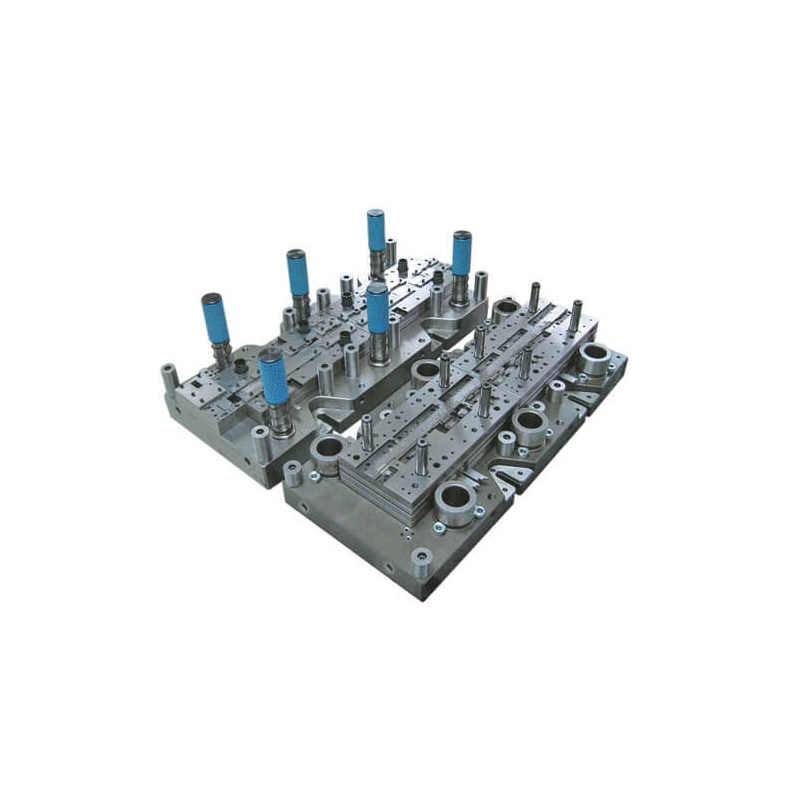

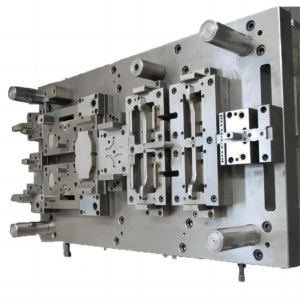

Mold Manufacturing Process:

- Product and Mold Design: Initial design phase where the product and mold are conceptualized and planned.

- Packaging: Preparation and packaging of components for the manufacturing process.

- Steel Preparation: Selection and preparation of steel for mold creation.

- Mold Testing: Conducting trials to ensure mold functionality and accuracy.

- Deep Hole Drilling: Precision drilling to create deep holes required in the mold structure.

- Assembly: Putting together various mold components.

- CNC Machining: Utilizing CNC machines for precise cutting and shaping of mold parts.

- Polishing: Final polishing to ensure a smooth finish and proper functionality of the mold.

Variety of Moulded Products

We also specialize in a wide range of related mould products, including:

- Soap Case on Shower Stand Moulds: Designed for creating durable and aesthetically pleasing soap cases.

- Sliding Cover Moulds: Ideal for manufacturing sliding covers with precise fitting and smooth operation.

- Friction Pad Moulds: Used to produce high-quality friction pads for various automotive applications.

- Fasten Nut Moulds: Essential for creating robust and reliable fastening nuts.

- Marbles Moulds: Used for the production of decorative and functional marbles.

- Non-Slip Mat Moulds: For manufacturing mats that provide excellent grip and safety.

- Decoration Ring Moulding: Perfect for creating decorative rings with intricate designs.

- Decoration Cover of Suspension Base Moulds: Specialized for making covers that enhance the look of suspension bases.

- Sprayer Body Injection Moulds: Used in the production of durable and efficient sprayer bodies.

Production Timeline

Our standard production timeline for plastic molds is 35-45 days, following a meticulous process to ensure quality and accuracy:

- Sample Submission: Customers provide samples.

- 3D Design: Our designers create a 3D model and send it for customer approval.

- Mold Design: Begin designing the mold.

- Material Procurement: Order the necessary steel.

- CNC Processing: Precision CNC machining.

- Electrosparking: Fine detail work on the mold.

- Mold Assembly: Assembling the completed mold.

- Testing: Conducting test injections.

- Sample Delivery: Sending plastic part samples to clients.

- Packing and Delivery: Final packaging and shipment.

- Customer Feedback: Collecting feedback for continuous improvement.

- New Orders: Process new orders based on feedback and demand.