Mould Manufacturing Process

- Inquiry Reception

– Promptly acknowledge and respond to customer inquiries.

- Quotation and Details

– Provide detailed pricing and relevant information within 16 hours.

- Drawing Submission

– Clients submit 2D/3D drawings along with specific mold requirements.

- Order Confirmation

– Confirm all order details, including quality specifications, pricing, materials, delivery schedules, and payment terms.

- Production Preparation

– Initiate production planning based on the client’s specifications.

- Mold Detail Confirmation

– Finalize and confirm the specific mold details with the client.

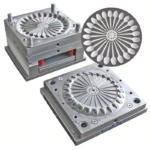

- Surface Shaping

– Execute precision operations such as drilling, high-speed carving, wire cutting, and EDM.

- Sample Testing

– Produce test molds and send samples to the client for evaluation.

- Feedback and Adjustments

– If necessary, receive client feedback and make the required adjustments to the mold.

- Repair and Finishing

– Perform any necessary repairs, polishing, and apply texture as needed.

- Sample Approval

– Submit revised samples until the client’s approval is secured.

- Delivery

– Arrange for delivery via sea, air, or other preferred methods as per the client’s instructions.

Customer Service Standards:

Pre-sale:

– Thorough Confirmation:Discuss and confirm product types and quantities with customers to ensure accuracy.

– Attentive Attention:Approach each inquiry with patience, seriousness, and attention to detail.

– Lead Time Management:Efficiently arrange production and closely monitor lead times to meet customer expectations.

– Careful Inspection:Conduct thorough inspections before delivery to ensure accuracy and quality.

After-sales:

– Prompt Delivery:Arrange delivery promptly after order confirmation.

– Delivery Confirmation:Confirm receipt of items by customers upon delivery.

– Feedback Collection:Gather feedback from customers and strive to provide the best possible service.

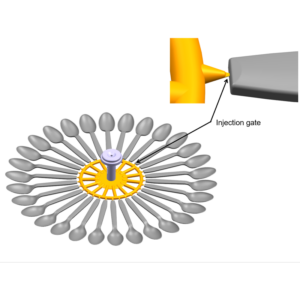

State-of-the-Art Injection Factory

Our injection molding shop is equipped with 15 injection machines of varying sizes, capable of handling parts up to 1.5m x 1.2m in size with a maximum capacity of 1228 tons. This diverse range of equipment allows us to cater to various production needs, ensuring flexibility and efficiency in manufacturing.