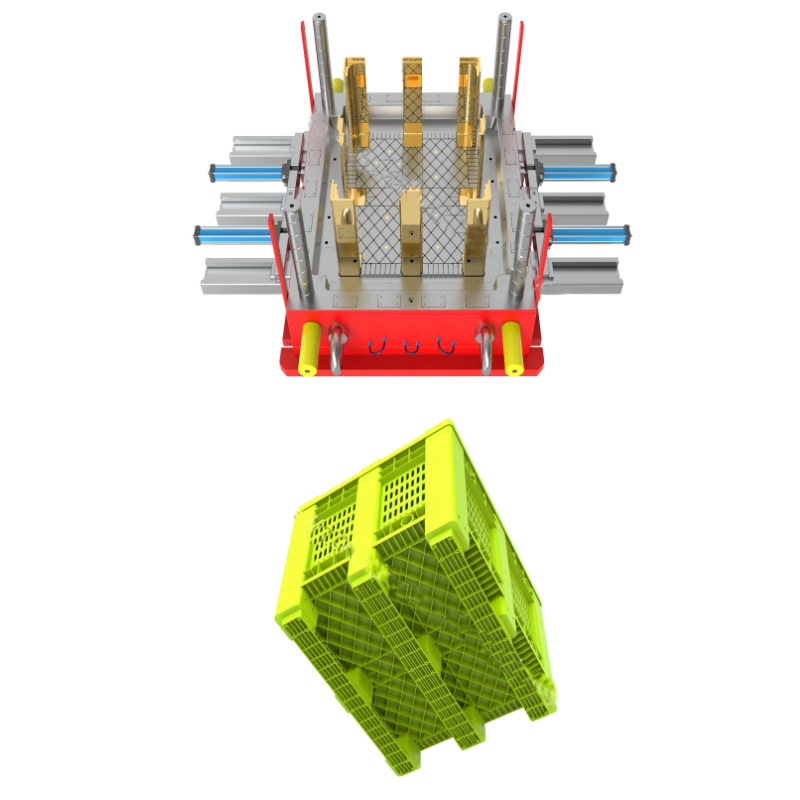

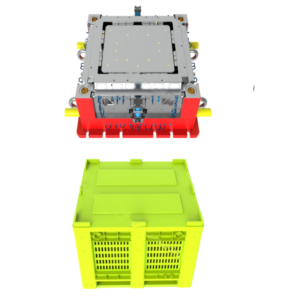

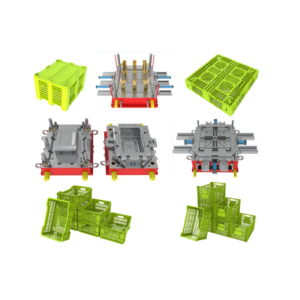

Customized 9-Foot Pallet Injection Molds for Industrial Use

A top-notch mould is essential for meeting production requirements smoothly and efficiently, minimizing downtime and maintenance costs.

At Toolingsun, our team of 6 experienced designers, each with over 20 years of expertise, focuses on meticulous mould design tailored to meet your specific needs. We prioritize customer specifications and details, offering cost-effective solutions without compromising on quality and stability. With extensive experience in exporting moulds, we ensure compliance with global standards and quality expectations.

Characteristics:

– Place of Origin: Xiamen, China

– Brand: OEM/ODM

– Model Number: Plastic Pallet Mould-002

– Product Material: Steel

– Runner: Hot Runner

– Mould Life: 300,000-3,000,000 Shots

– Mould Base: Self-Made / LKM / HASCO

– Delivery Time: 70 Days

– Mold Cavity: 1 cavity

– Mould Steel: P20/718/H13

– Injection Machine Size: 1800 Tons

– Mold After-sales: Free Mould Parts

– Advantage: Free 3D Drawing Design

Mold Production Process:

- Design Phase:

– 3D Drawing: Initial design of pallet products to visualize the concept.

- Prototype Development:

– Testing Sample: Creating prototypes for testing and evaluation.

– 3D Structure: Developing the detailed structure of the mold.

- Mold Manufacturing:

– Prepare Metal: Selecting and preparing the appropriate metal for mold construction.

– CNC Working: Precision machining of mold components.

– Engrave Working: Adding necessary engravings or markings.

– Mirror Polishing: Ensuring smooth and flawless surfaces.

- Testing and Approval:

– Mould Testing: Conducting thorough testing to ensure functionality.

– Sending Sample: Sending samples to customers for evaluation.

– Good Feedback: Gathering feedback and making necessary adjustments.

- Final Production:

– Confirm Sample: Confirming the sample design for mass production.

– Final Goods: Producing the final goods according to approved specifications.

- Packaging and Shipping:

– Prepare Shipping: Preparing for shipping logistics.

– Package Mould: Securely packaging the molds.

– Loading Container: Loading containers for delivery.

Customer Visits:

- Factory Tours:

– Customers visit our factory annually to engage in face-to-face communication, gain comprehensive insights, and finalize mold contracts.

- Client Engagement:

– Our business personnel and mold engineers actively visit both new and existing clients to deliver quality service and support, ensuring enhanced satisfaction for our global clientele.

Injection Mold Production Process:

- Mold Preparation:

– Prepare mold steel and materials according to specifications.

- CNC Machining:

– Utilize CNC machines for precise shaping and detailing of mold components.

- Drilling and Milling:

– Perform deep hole drilling and high-speed milling for intricate mold features.

- EDM (Electrical Discharge Machining):

– Employ EDM for precise shaping and finishing of mold cavities and details.

- Polishing and Assembly:

– Conduct thorough polishing and meticulous assembly of mold parts.

- Mold Trial:

– Conduct trial runs to ensure mold functionality and quality meet standards.

- Surface Treatment:

– Apply electroplating and nitriding treatments for enhanced durability and surface finish.

- Size Control and Inspection:

– Strictly control dimensions and tolerance limits based on 3D drawing requirements, with self-inspection of each mold part.