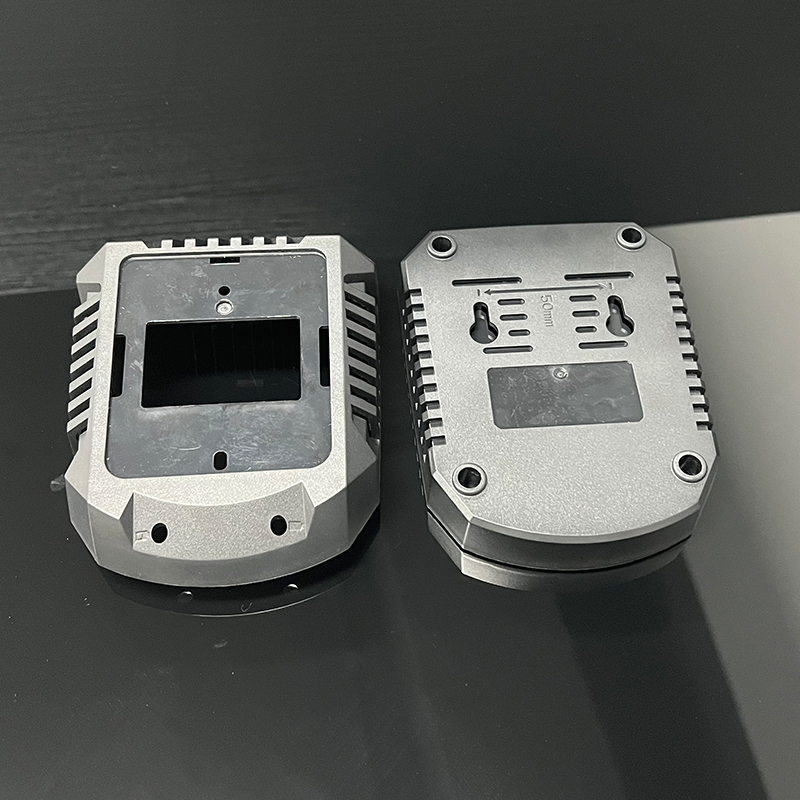

Expert Injection Molding Services for Customized Plastic Battery Cases

Injection Molding Expertise

At the heart of our injection molding service is the injection mold, the pivotal component that defines the entire process. This essential mold consists of several key parts: the Tooling Base, Core and Cavities, Ejection Systems, and Cooling Systems. Together, these components ensure the precision and quality of the final product.

Critical Factors in Injection Mold Service

An effective injection molding service hinges on several critical factors:

Material Selection: Choosing the right materials is crucial for durability and performance.

Meticulous Mold Design: Detailed and accurate mold design ensures the efficiency and quality of the molding process.

High-Precision Tools: Creating tools with high precision is essential for producing consistent and reliable parts.

Years of Expertise

With years of experience in the industry, we deliver high-quality injection molds and molding services. Our extensive knowledge in material selection, mold design, and precision tooling ensures top-notch results for our clients.

Our Distinctive Advantages

Seasoned Professional Team:

Our team boasts over 15 years of expertise, specializing in Automotive, Medical, and Electric Molds & Products. Their experience and dedication ensure high-quality outcomes for every project.

Cutting-Edge Equipment:

We utilize world-class processing and quality control equipment from renowned brands like AgieCharmilles, Mitsubishi, Röders, MAKINO, Serein Croma-C, and GOM ATOM. This advanced equipment ensures precision and reliability in our injection molding services.

Medical Clean Room Facilities:

Our facilities include a 100k-grade clean room for medical molding products and a 10k-grade laboratory, ensuring the highest standards of quality. This capability positions you to secure orders and bids in the medical sector with confidence.

Internationally Recognized Certifications:

Our operations are backed by certifications such as ISO 9001 and IATF 16949, demonstrating our commitment to maintaining high-quality standards.

Unmatched Precision:

We guarantee standard precision at 0.02mm, with the capability to achieve even higher precision based on specific requirements. This ensures that each product meets exact specifications and quality standards.

End-to-End Manufacturing:

We offer a seamless process from mold design to production and molding of products. This comprehensive approach saves time and costs while maintaining strict control over quality and schedules.

Comprehensive Services for Plastic Battery Cases

Choose us for a holistic approach to plastic battery box molding and injection molding cases. Our commitment to excellence ensures that every project is executed to the highest standards, providing you with reliable, high-quality products.

Experience the benefits of our expert injection molding services, where excellence is not just a standard but a commitment. Whether you need customized plastic battery cases or other injection molded products, we deliver solutions that meet your precise needs and exceed your expectations.