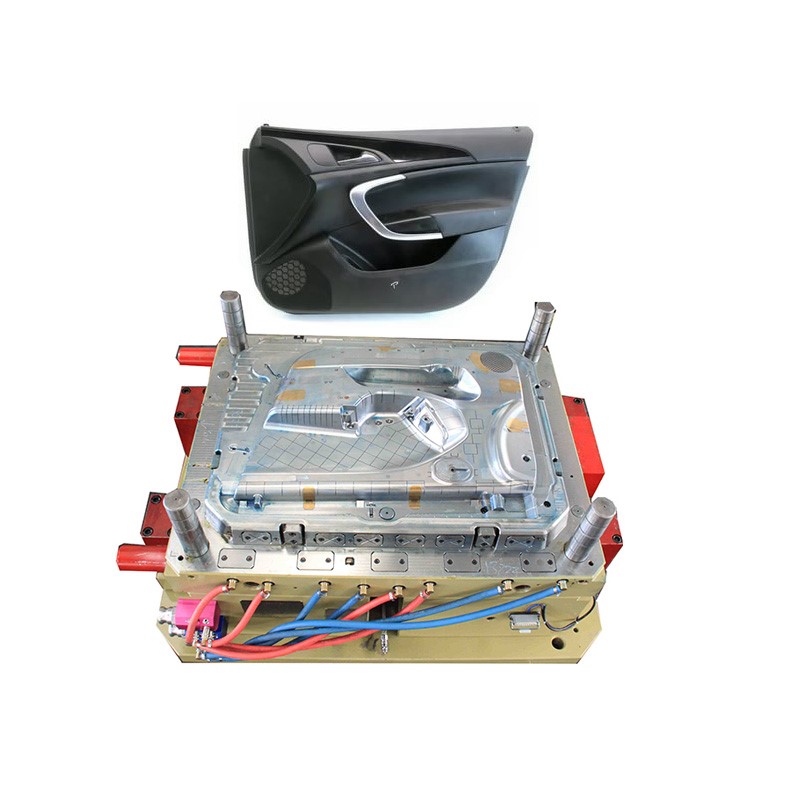

Car Door Panel Molding

The car door panel is an essential component of any vehicle, designed to fit the specific contours and functional requirements of the car’s design. Due to its irregular shape, the car door panel is typically produced using the injection molding method. This process is ideal for creating complex plastic products, making it the preferred technique for manufacturing thermoplastic and thermosetting materials into various automotive parts.

Injection Molding Process

Injection molding is a highly efficient production method that involves using an injection molding machine and a precisely designed mold to create the desired car door panel. The process begins with the melting of plastic material, which is then injected into the mold cavity. Once cooled and solidified, the mold opens to release the finished car door panel, ready for further assembly and installation.

Design Specifications for Car Door Panel Mold

The mold for car door panels must accommodate the unique design and functional aspects of the vehicle. Typically, cars have either two or four doors, with molds specifically designed for the left and right door panels. The material used for these molds is a blend of polypropylene (PP) and ethylene propylene diene monomer (EPDM). This combination offers excellent properties such as:

- Shrinkage Rate: The shrinkage rate for the material is generally 1.011.

- Material Properties: EPDM rubber is a copolymer of ethylene, propylene, and a small amount of non-conjugated diene, which contributes to its chemical stability, ozone resistance, heat resistance, and weather resistance. This enhances the elasticity and durability of the car door panel.

Advantages of Using Customized Molds

Customized car door panel molds offer several advantages to ensure high-quality production and efficient processing:

- Precision Cooling: The interior water ducts of the mold maintain a distance of at least 8 mm from pusher holes, such as push rods and push blocks. This ensures uniform cooling, which is critical for maintaining the dimensional stability of the door panel.

- Balanced Temperature Control: The cooling water channels are designed to be approximately equal in length, ensuring a consistent temperature difference between the inlet and outlet. This uniform cooling helps maintain a stable mold temperature, essential for producing high-quality parts.

- Enhanced Drilling Techniques: To accommodate the shape of the plastic part, the mold uses large-angle oblique holes. Although these can cause side slip during drilling, this issue is mitigated by milling a platform perpendicular to the inclined hole before drilling. This ensures accurate and reliable mold production.

Customized car door panel molds are crucial for producing high-quality, durable automotive components. By utilizing advanced injection molding techniques and carefully designed molds, manufacturers can ensure that car door panels meet stringent quality and performance standards.