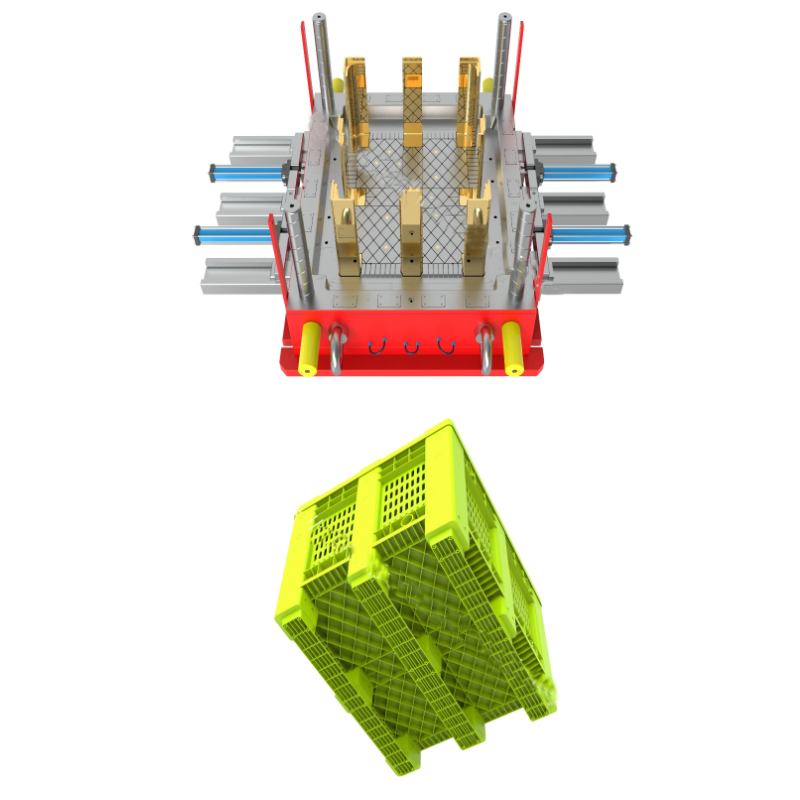

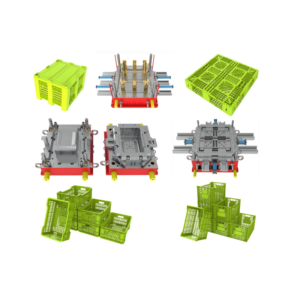

Customized Mould Tooling for Industrial Pallet Box Crate

Product Details:

| Injection Mould Name | Plastic Pallet Box Mould |

| Mould Core and Cavity Metal | P20 |

| Injection Machine Size | 3000 Tons |

| Demould Type | Automatic |

| Metal Hardness | HRC 28-32 |

| Mould Base | Self-Made LKM DME |

| Mould Runner | Cold Runner & Hot Runner |

| Cavity Number | 1 Cavity |

| Cycle Time | 300 Seconds |

| Tooling Lead Time | 90 Days |

| Mould Life | 30-300 Million Shots / 5-6 Years (Can last up to 10 years in good condition) |

| Mould Surface Treatment | EDM, Texture Mirror Polishing |

Main Mould Metal Materials and Hardness:

– Steel Model:

– P20

– 718H

– H13

– 2344

– S136

– Hardness (HRC):

– P20: 28-32

– 718H: 33-38

– H13: 48-50

– 2344: 48-52

– S136: 48-52

– Mould Life:

– P20: >300,000 shots

– 718H: >500,000 shots

– H13: >800,000 shots

– 2344: >800,000 shots

– S136: >1,000,000 shots

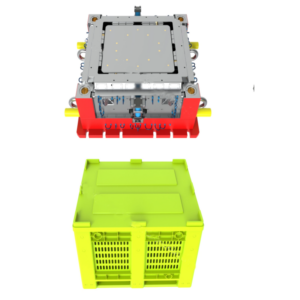

Crafting High-Quality Injection Pallet Moulds:

- Mould Design

-Feasibility Analysis:Comprehensive assessment of plastic product feasibility, considering factors like shrinkage and optimal molding temperature.

-Customer Consultation:Engage in detailed discussions with clients regarding product specifications, encompassing weight, design aesthetics, size, appearance, as well as aspects of stability and wear resistance.

-Free Design and Mold Flow Analysis:Offer complimentary design services and conduct mold flow analysis to ensure optimal performance and efficiency.

- Mould Metal Material Selection

– Steel Choice:Select steel based on plastic product material, desired mould life, and customer specifications.

– Quality Assurance:Source mould raw materials exclusively from reputable metal companies.

– Hardness Testing:Conduct thorough hardness testing of the mould steel to ensure quality and durability.

– Stringent Inspection Procedures:Adhere to rigorous inspection protocols for mould steel hardness, ensuring reliability and longevity.

– Mould Life:Achieve mould life ranging from 300,000 to 3 million shots through meticulous material selection and quality control measures.

- Mould Testing Procedure

– Initial Mold Inspection:Conduct initial testing to ensure smooth and accurate movement of the mould components.

– Post-Polishing Assessment:After polishing the pallet mould, conduct another round of testing to compare test samples with the original design.

– Customer Confirmation:Provide final samples and a video demonstrating pallet mould testing to customers for their approval.

Shipping Details:

- Functional Check:Verify smooth operation of the plastic mould’s opening and closing mechanism, as well as the functionality of the water cooling, hydraulic oil, and hot runner systems.

- Cleaning Process:Ensure thorough cleaning of the cavity and core to remove any iron filings or impurities.

- Waterway Maintenance:Clean and blow dry the waterway to prevent rusting during long-term sea transportation.

- Rust Prevention Measures:Apply anti-rust agent to the interior, spray paint on the exterior, and coat the thimble with anti-rust oil.

- Identification Labeling:Affix a nameplate to the mould indicating its name, year of production, relevant information, as well as weight and size details.

- Free Mould Parts:Provide complimentary mould parts for convenient customer replacement.