Product Specifications:

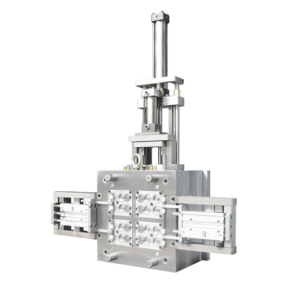

– Runner Type: Hot Runner

– Design Software:UG

– Installation Type: Fixed

– Certification: ISO

– Customization: Available

– Transport Packaging:Pry Wood Box

– Specification:Customization

– Trademark:OEM

– Place of Origin:Xiamen, China

– Production Capacity:500sets Per Year

Quality Assurance & Service:

– Lifetime After-Sales Support: We offer lifetime sales-after service for all injection molds, ensuring your complete satisfaction.

– Quick Response: Our team guarantees a 24-hour response time to address all your questions and comments promptly.

– Steel Quality Warranty: Our mold steel comes with a lifetime quality warranty. For 40HRC steel, we offer a 100K shots warranty, and for 45HRC steel, a 1000K shots warranty.

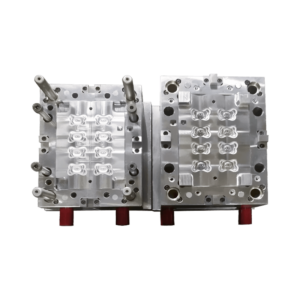

– Precision Manufacturing: All products are CNC machined and prototyped according to drawings. We conduct a 100% size check before shipment to ensure accuracy.

– Comprehensive Documentation: Our engineering team provides material certification, dimension reports, design checklists, and complete mold shipment details for your peace of mind.

Customization Service for Molds

– Design Consultation:Work together with clients to fully grasp their unique design needs and preferences.

– Technical Drawings:Develop precise technical drawings and specifications according to client feedback.

– Material Selection: Provide guidance in selecting the right materials for the mold and final product to ensure optimal performance.

– Tooling Development:Develop custom tooling and molds tailored to meet precise specifications and production needs.

– Prototype Production:Produce prototypes to validate design, functionality, and material choices before full-scale production.

– Mold Fabrication:Utilize advanced manufacturing techniques to create high-quality, durable molds.

– Surface Finishing:Apply various surface treatments, including polishing, coating, and texturing, to meet aesthetic and functional requirements.

– Testing and Validation:Conduct rigorous testing of molds to ensure they meet quality standards and performance expectations.

– Adjustments and Iterations: Make necessary adjustments and refinements based on prototype testing and client feedback.

– Production Support:Provide ongoing support throughout the production process, including troubleshooting and maintenance.

– Quality Assurance: Implement stringent quality control measures to ensure the molds meet industry standards and client specifications.

– Delivery and Installation:Manage logistics for timely delivery and offer installation support to ensure seamless integration into the production line.