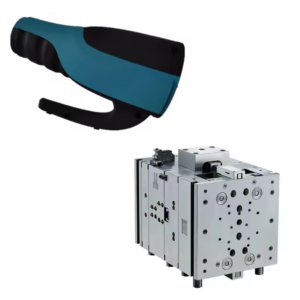

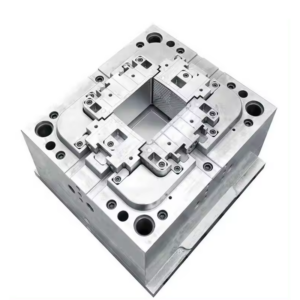

Customized Professional Precision Electronic Products Plastic Injection Mold

Characteristics:

– Origin: Manufactured in Xiamen, China

– Brand: OEM/ODM

– Material: Plastic (ABS/PA66/PP/PC/PMMA/PSU/PCTG/TPE/TPU/PBT)

– Mold Life: 50,000-500,000 shots

– Surface Treatment: Textured finish

– Cavity: Multi-cavity

– Mold Base: LKM, HASCO

– Delivery Time: 20-35 Days

– Usage: Designed for Decorative Garden Paving Stone Mold

– Business Type: Manufacturer

– Certificate: OHSMS18001

Our Services:

- Product Design and Development:

– Design and modify products based on samples

– Custom plastic mold design

- Injection Molding:

– Custom injection molding parts production

– Small volume production capabilities

- Casting and Finishing:

– Vacuum casting parts production

– Comprehensive finishing options including polishing, matte finish, spray painting, silk screening, anodizing, chrome plating, and assembly

- Mold Services:

– Mold design flow analysis and DFM report

– Custom plastic molds, hot compression molds, and stamping molds

- Manufacturing Processes:

– Plastic injection molding

– Hot compression and stamping punching processes

Business Terms:

– Detailed CAD or 3D drawings, or samples are required for production.

– All products will be manufactured and delivered based on approved client drawings.

– We strictly maintain confidentiality regarding our customers’ product information.

– Intellectual property rights of the product belong solely to the client, independent of our company.

Trade Terms:

– Available trade terms: EXW, FOB, CIF, or as required.

Payment Terms:

– Payment: 50% remittance by T/T in advance, balance 50% before shipment.

Lead Time (T0 and T1):

– T0 Time: Starts from the deposit received in our account until client confirms the design.

– T1 Time: Begins after the customer confirms the 3D mold drawing until we arrange courier samples for client confirmation.

Customer Visits:

– You are welcome to visit our facilities. During special circumstances, virtual factory tours via video are also available upon request.

After-Sales Service Overview:

– Personalized Support: We offer 24-hour one-to-one engineer support and technical assistance.

– Progress Updates: Continuous progress reports to keep you informed throughout the process.

– Quality Assurance: Rigorous quality control measures ensure the highest standards are maintained.

– Free Maintenance: We provide free maintenance for all molds processed by our company.

Plastic molds play a crucial role in the production of electronic products. Our customized electronic product plastic mold service delivers precise, efficient, and professional solutions tailored to our customers’ needs, reflecting the industry’s demand for personalized services in today’s electronics-driven world.