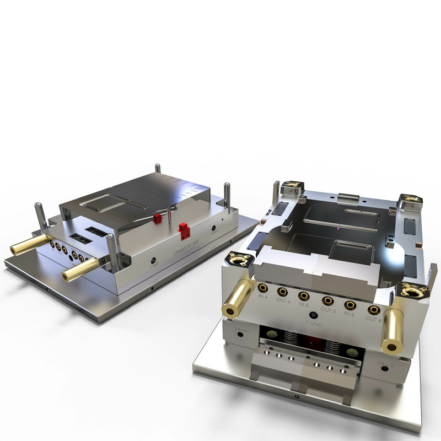

Die Mould Tooling refers to precision-engineered tools used in manufacturing processes like metal stamping, injection molding, and die casting. These tools ensure accurate shaping, cutting, and forming of materials into desired components. Advanced factory production techniques guarantee high durability, precise dimensions, and customization options for various industrial applications, including automotive, aerospace, and consumer electronics.

Basic Information

Mold Type: Plastic Injection Mold

Mold Material Options:P20, 718, 738, NAK80, S136

Mold Base Standards: HASCO, DME, MISUMI, JIS, LKM, etc.

Mold Runner System:Cold Runner / Hot Runner

Mold Gate Options:Slide Gate, Sub Gate, Pin-point Gate

Cavity:Single or Multi-Cavity

Design Software Supported:UG, PROE, CAD, SOLIDWORKS

Molding Equipment Used:CNC, Wire Cutting, Milling Machine, EDM

Compatible Raw Materials:ABS, PP, PC, PA6, PA66, PVC, POM, PMMA, PS, etc.

Packaging Method:Wooden pallet or carton

OEM Services:Available—please provide 2D/3D files or samples

Lead Time:Approximately 30 days

Why Choose Us?

-

Multi-Language Capability:

– Our team is proficient in multiple languages, ensuring seamless communication with clients from diverse linguistic backgrounds. This capability allows us to effectively understand and meet your specific needs, regardless of your location.

-

On-Site Material Inspection:

– We conduct thorough on-site inspections of all materials before they are used in production. This rigorous process ensures that only the highest quality materials are utilized, maintaining the integrity and durability of the final product.

-

Design-Based Customization

– We offer extensive customization based on your design requirements. Our experienced engineers collaborate closely with you to develop molds that precisely match your specifications, ensuring optimal performance and functionality.

-

Finished Product Inspection:

– Each finished product undergoes a comprehensive inspection to verify it meets all quality standards and customer specifications. This meticulous approach guarantees that you receive products of the highest quality and reliability.

-

Sample-Based Customization:

– We provide customization based on sample submissions. This process allows us to replicate and enhance existing designs, ensuring the final product aligns perfectly with your expectations.

-

Full Customization:

– We offer full customization services, tailoring every aspect of the mold to your specific needs. From design to production, we ensure that every detail is customized to meet your unique requirements.

Quality Documentation

- ISO 9001:2015 Certification

- IATF 16949 Certification

- First Article Inspection (FAl)

- PPAP Report(Production Part Approval Process)

- Material Technical Data Sheets (TDS)

- CMM Inspection Report

- SPC Report (Statistica Process Control)

- Material Certificates

- Dimensional Inspection Report (CMM)

- DFM feedback