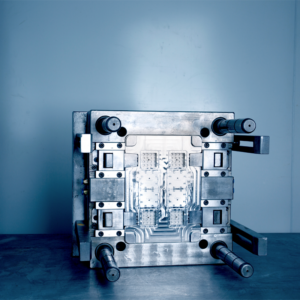

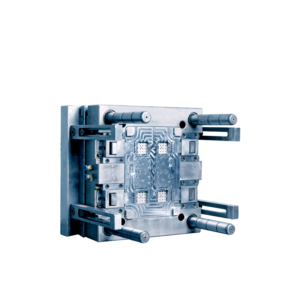

Key Specifications

Shaping Mode: Injection Mould

Mould Cavity: Multi Cavity

Plastic Material: ABS, PP, PC, PVC, PA, PU, PE, PEEK, POM, PMMA, PEE

Runner System: Hot Runner

Design Software: UG (Unigraphics)

Certifications: ISO9001, IATF 16949

Customization: Available

Customization Service for Molds

– Design Consultation:Collaborate with clients to understand specific design requirements and preferences.

– Technical Drawings:Create detailed technical drawings and specifications based on client input.

– Material Selection:Assist in choosing appropriate materials for both the mold and the final product to ensure optimal performance.

– Tooling Development:Develop custom tooling and molds tailored to meet precise specifications and production needs.

– Prototype Production:Produce prototypes to validate design, functionality, and material choices before full-scale production.

– Mold Fabrication:Utilize advanced manufacturing techniques to create high-quality, durable molds.

– Surface Finishing:Apply various surface treatments, including polishing, coating, and texturing, to meet aesthetic and functional requirements.

– Testing and Validation:Conduct rigorous testing of molds to ensure they meet quality standards and performance expectations.

– Adjustments and Iterations: Make necessary adjustments and refinements based on prototype testing and client feedback.

– Production Support:Provide ongoing support throughout the production process, including troubleshooting and maintenance.

– Quality Assurance: Implement stringent quality control measures to ensure the molds meet industry standards and client specifications.

– Delivery and Installation:Manage logistics for timely delivery and offer installation support to ensure seamless integration into the production line.

Advantages of Injection Molding

Injection molding is a cost-effective method to produce precise and durable plastic components for the automotive industry. The process is quick, accurate, and capable of producing strong parts that meet the stringent requirements of car manufacturers. It is particularly suited for manufacturing small components like clips and fasteners, making it an ideal choice for automotive applications. Additionally, injection molding boasts high automation and repeatability, ensuring consistent quality in every batch.