High Precision Moulding and Tools refer to advanced manufacturing solutions used to create complex and accurate components with tight tolerances. These tools ensure precise shaping, consistent quality, and high efficiency in production processes. They are essential in industries such as automotive, aerospace, electronics, and medical devices, where accuracy and durability are critical.

Basic Information

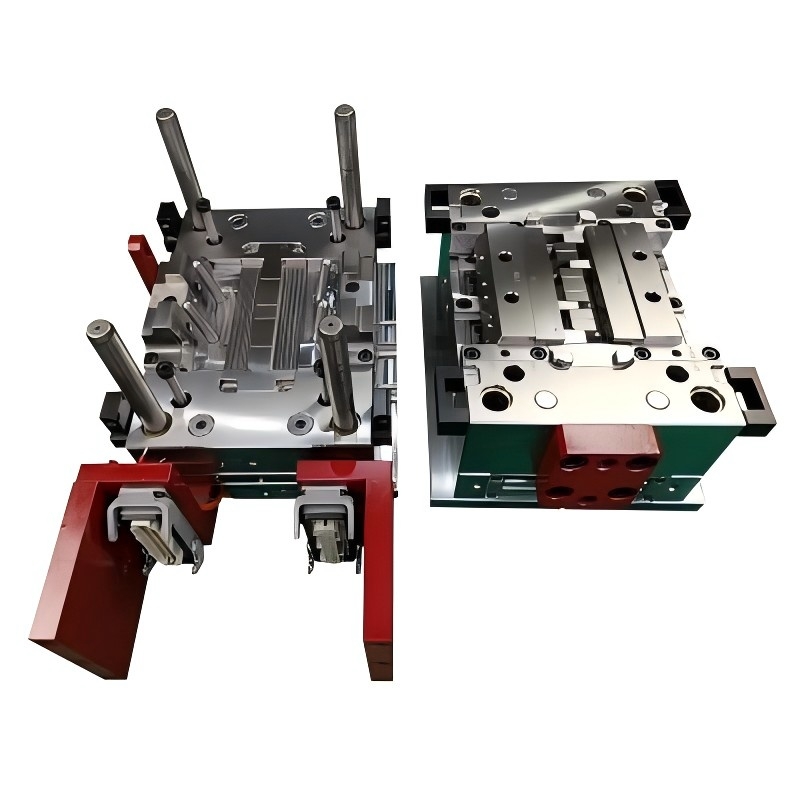

Mold Type: Plastic Injection Mold

Mold Material Options:P20, 718, 738, NAK80, S136

Mold Base Standards: HASCO, DME, MISUMI, JIS, LKM, etc.

Mold Runner System:Cold Runner / Hot Runner

Mold Gate Options:Slide Gate, Sub Gate, Pin-point Gate

Cavity:Single or Multi-Cavity

Design Software Supported:UG, PROE, CAD, SOLIDWORKS

Molding Equipment Used:CNC, Wire Cutting, Milling Machine, EDM

Compatible Raw Materials:ABS, PP, PC, PA6, PA66, PVC, POM, PMMA, PS, etc.

Packaging Method:Wooden pallet or carton

OEM Services:Available—please provide 2D/3D files or samples

Lead Time:Approximately 30 days

Quality Documentation

- ISO 9001:2015 Certification

- IATF 16949 Certification

- First Article Inspection (FAl)

- PPAP Report(Production Part Approval Process)

- Material Technical Data Sheets (TDS)

- CMM Inspection Report

- SPC Report (Statistica Process Control)

- Material Certificates

- Dimensional Inspection Report (CMM)

- DFM feedback

Application

-

Medical:

– Our molds and tooling solutions are essential for manufacturing high-precision medical components, including surgical instruments, diagnostic devices, and implantable medical products. These tools are designed to meet stringent medical standards, ensuring biocompatibility, durability, and exacting tolerances required for safe and effective medical applications.

-

Automotive:

– In the automotive industry, our mold and tooling services support the production of critical components such as engine parts, interior trims, dashboards, and exterior body panels. Our advanced tooling solutions ensure high performance, precision, and durability to meet the demanding quality and safety standards of the automotive sector.

-

New Energy:

– Our expertise in mold and tooling is pivotal for the new energy sector, particularly in the manufacturing of components for solar panels, wind turbines, and energy storage systems. We provide high-quality molds that enable efficient production processes, contributing to the development of sustainable energy solutions.

-

Drone:

– For the rapidly growing drone industry, we offer specialized molds and tooling for the production of drone frames, propellers, and other key components. Our solutions ensure lightweight, durable, and aerodynamically optimized parts, enhancing the performance and reliability of drones for various applications.

-

Aerospace:

– In the aerospace industry, precision and reliability are paramount. Our molds and tooling solutions are used to produce components for aircraft, satellites, and space exploration equipment. We ensure that every part meets the highest standards of aerospace engineering, contributing to the safety and performance of aerospace technologies.

-

Electrical Appliance:

– Our molds and tooling are essential for the production of various electrical appliances, including household gadgets, consumer electronics, and industrial equipment. We focus on delivering high-quality, durable, and precise components that ensure the efficiency and longevity of electrical appliances.

-

Battery Equipment:

– We provide specialized molds and tooling for the battery industry, supporting the production of battery casings, connectors, and other critical components. Our solutions ensure high precision and reliability, essential for the performance and safety of batteries used in various applications, including electric vehicles and portable electronics.

-

5G Device:

– As the demand for 5G technology grows, our molds and tooling services play a crucial role in manufacturing components for 5G devices. We enable the production of high-precision parts for smartphones, base stations, and other communication devices, ensuring that they meet the performance and connectivity standards required for 5G technology.