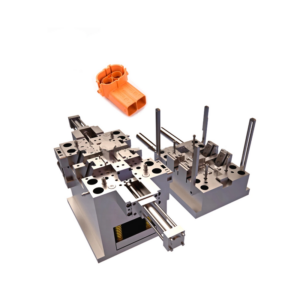

High Precision Terminal Connector Electric Plastic Injection Molding Mould

Features:

| Item | Details |

| Design Software | UG, Pro-E, AutoCAD, CATIA |

| Installation | Fixed |

| Runner | Cold/Hot Runner (YUDO, HRS, Moldmaster, HUSKY, DME, local brands, etc.) |

| Standard | LKM, HASCO, DME, FUTA, etc. |

| Cavity | Single/Multiple Cavities |

| Mould Base | P20, 45#, 4CR13, etc. |

| Mould Life | 0.2-2 million Shots |

| Mould Material | P20, P20H, 718, 718H, 2738, Nak80, S136, SKD61, 8407, H13, 2343, 2344, 2311, 2312, 2379, 2316, 2093, 2767, etc. |

| Plastic Material | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO, etc. |

| Surface | Heat treatment, polishing, texture, coating, etc. |

| Gate | Side gate, Edge gate, Submarine, Pin Point, Horn, Direct gate, Capillary, etc. |

| Tonnage | 50-3600T |

| T1 Time | 30-40 days |

| Specification | Customized |

| Transport Package | Plastic bag, Carton box, Wooden Case |

| HS Code | 8480719090 |

| Industry | Automotive, Communications, Electronics, Home Appliances, Household products, etc. |

Packaging & Shipping Process:

– Apply anti-rust agent to the mould

– Place the mould in an export-grade plywood case

– Lubricate guide columns and ejector pins

– Wrap the mould securely in plastic wrap

– Install the mould properly

– Lubricate the mould again before shipping

– Ship via express, air, or sea transport

Surface Treatments:

Polishing

Provides a smooth and shiny surface finish, enhancing the appearance and performance of the mold.

Painting

Applies a protective and decorative coating to the mold surface, available in various colors and finishes.

Chroming

Adds a layer of chromium to the mold surface, offering corrosion resistance and a reflective finish.

Anodizing

Electrochemical process that increases the thickness of the natural oxide layer on the surface, improving durability and resistance to wear.

Silk Screening

Technique for applying ink through a stencil to create detailed and precise markings or logos on the mold surface.

Laser Marking

Uses laser technology to engrave or etch precise and permanent markings on the mold surface without using any inks or tools.

Texture

Adds specific patterns or textures to the mold surface, enhancing grip and aesthetic appeal while providing functional benefits like reduced friction.

FAQS:

Q1: Do you offer OEM services?

A:Yes, we specialize in providing OEM services.

Q2: What information do I need to provide for a custom product quote?

A: Please send us 2D or 3D drawings (.step, .stp, .igs, .dwg preferred) or samples, along with detailed requirements.

Q3: What is the process for customizing a product?

A:

- Design the mold based on product drawings or samples.

- Confirm the drawings with the customer.

- Manufacture the mold.

- Conduct T1 testing and send samples to the customer for feedback.

- Adjust the mold, retest, and send revised samples for customer approval.

- Receive final confirmation from the customer.

- Dispatch the mold or begin mass production.

Q4: What should I do if I receive defective molds or products?

A: We take full responsibility for any defects. We will promptly rework or reproduce at our expense. For defective parts, we will either replace them or provide a full refund. If you encounter any issues, please contact us immediately.