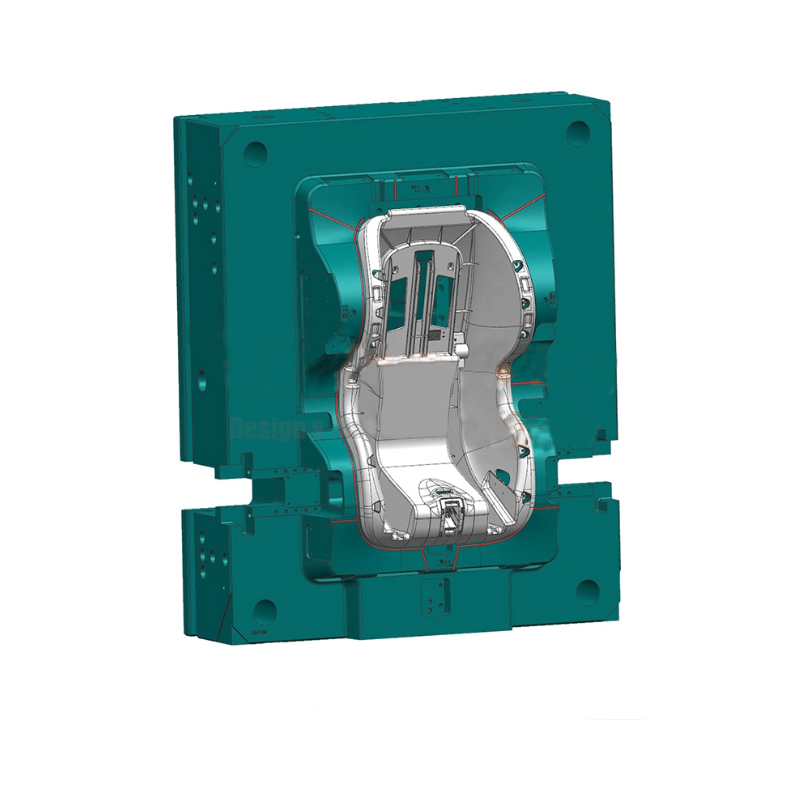

High-Quality Low-Cost Molding for Baby Car Seats

Details:

| Basic Info | Details |

| Model Number | HM146 |

| Application | Automotive, Home Use |

| Runner Type | Hot Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | TS16949, ISO9001, SGS |

| Standard | HASCO |

| Customization | Available |

| After-Sales Service | 24/7 Support |

| Mold Heat Treatment | Quenching, Nitridation, Tempering, etc. |

| Cooling System | Water Cooling or Beryllium Bronze Cooling, etc. |

| T1 Lead Time | 45-60 Days |

| Mold Precision | +/-0.01mm |

| Transport Packaging | Wooden Case |

| Specifications | Based on Customer Requirements |

| Place of Origin | Xiamen, China |

| HS Code | 8480719090 |

| Production Capacity | 500 Sets/Year |

Features:

Mold Processing

Upon confirmation of the mold drawing, we commence production, which includes steel preparation, CNC rough machining, deep hole drilling, EDM, drilling, high-speed milling, and finishing assembly. Our molds are crafted from high-quality steels ensuring a long service life and manufactured with advanced equipment to achieve a tolerance of +/- 0.01mm. The finished products have a flawless appearance without flash and integrate seamlessly with other components. Featuring an efficient equilibrium cooling system and high-precision machining, each part of the mold is meticulously crafted from carefully selected steel. Additionally, our molds utilize hot runners with valve gates to enhance efficiency.

Our Main Products

- Molds for Household Components

- Molds for Appliance Parts

- Molds for Automotive Parts

- Molds for Thin-Wall Components

- Molds for Industrial Parts

Our Equipment

– Five-axis high-speed milling machines

– Three-axis high-speed milling machines

– CNC milling machines

– Deep hole drilling machines

– Large-scale milling machines

– CNC engraving machines

– Electrical Discharge Machines (EDM)

Mold Shipment Details

Quality Inspection of Plastic Mold Installation:

We conduct a comprehensive inspection of the plastic mold to ensure structural integrity and part standardization. The project manager and quality inspection personnel follow the company’s standards to verify product quality. Immediate corrections are made if issues are detected to prevent errors. Continuous testing of the cooling system, hydraulic oil duct system, and hot runner system is also performed.

Pre-Shipment Mold Check:

- Once the customer approves the sample, our manager instructs the team leader to review the mold, including the 3D mold design, customer specifications, and any trial issues.

- Our inspector verifies the mold based on the provided documentation.

- If required, we provide water and oil channel drawings and pictures of the mold water transport system.

- After thorough inspection, the team leader is notified to pack the mold.

Mold Specifications:

- The team leader completes the instruction form.

- All mold accessories are packed into a wooden case.

- A mold trial report, usage instructions, temperature control box instructions, and quality certification are prepared for the customer.

Mold Packing:

- Clean the cavity and core to remove any iron filings.

- Spray antirust paint inside and outside the mold.

- Wrap the mold with plastic film.

- Place the mold in a wooden case or on a wooden pallet.

Mould Design features& Sample Display: