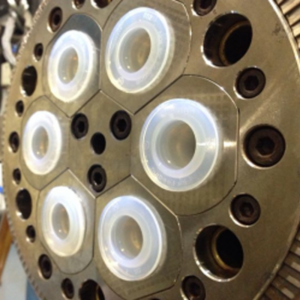

High-Quality Overmolding LSR Mold for Composite Gasket

LSR molds are specialized equipment designed for manufacturing LSR parts with exceptional precision and the ability to produce parts with complex geometries. Liquid silicone rubber flows seamlessly into the mold, allowing intricate details and gaps to be reproduced with extreme precision. Additionally, LSR molds are known for their high quality and durability, and silicone rubber is resistant to extreme temperatures, chemicals, and UV radiation, making it ideal for harsh environments. Additionally, LSR mold parts have excellent elasticity, allowing them to withstand tension and compression without affecting their shape or functionality.

Main Features:

Cost Efficiency of Silicone Injection Molds:

Silicone injection molds provide significant cost advantages through enhanced production efficiency and optimized material usage. Their capability to facilitate rapid cycle times and high-volume production translates to heightened productivity and decreased manufacturing expenses.

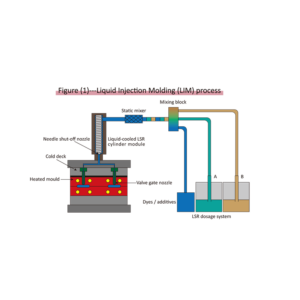

The manufacturing process of LSR tooling:

The manufacturing process of LSR tooling involves a series of precise steps. Initially, the liquid silicone rubber is meticulously blended with a catalyst and any essential additives. Subsequently, this mixture is meticulously injected into a specialized mold using precision machinery. Typically crafted from steel or aluminum, the mold is intricately designed to impart the desired shape and features onto the part.

Following the injection, the mold undergoes a controlled heating process to facilitate the curing of the silicone rubber. The duration of the curing process varies, contingent upon the size and intricacy of the part. Upon completion of the curing phase, the finished part is carefully extracted from the mold, and any surplus material is meticulously trimmed away.

Researching And Developing Capability:

Toolingsun is a well-known industry leader in precision mold manufacturing and rubber molding services, providing expertise in rubber compression molding, rubber transfer molding, liquid silicone rubber molding and rubber injection molding to meet different product specifications. Our in-house tool manufacturing facility is dedicated to minimizing production costs and ensuring tight tolerances. We cater to a wide range of manufacturing quantities, from prototypes and low-volume production to large-scale production. Additionally, our capabilities extend to reverse engineering products from samples, allowing us to meet different technical requirements. We specialize in delivering consistently accurate molded rubber products, and we pride ourselves on meeting precise specifications and ensuring optimal functionality in a variety of applications.