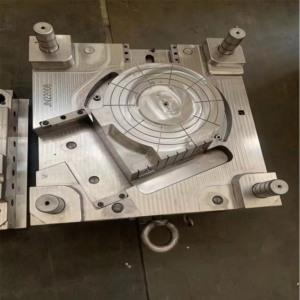

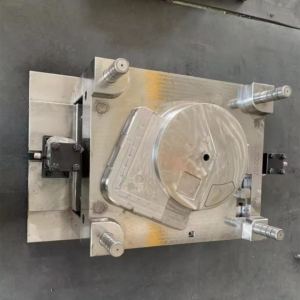

High-Quality Plastic Injection Molds for Industrial Use

Toolingsun is a distinguished manufacturer renowned for its expertise in plastic injection molds. Specializing in an extensive array of products including household items, furniture, and industrial molds, we are committed to delivering superior quality, precision, and innovation to clients worldwide.

Our comprehensive portfolio features a diverse range of molds, ranging from essential household items such as chairs, tables, and buckets to specialized products like baby bathtubs, flowerpots, and storage boxes. We also cater to industrial needs with molds for crates, washbasins, and pallets. Our dedicated team of highly skilled technicians and engineers ensures meticulous design and production, meeting even the most stringent specifications.

At Toolingsun, we pride ourselves on being your trusted partner, providing solutions that exceed expectations in quality and reliability.

Features:

| Parameter | Details |

| Mold Material | P20, 2738, 718H, NAK80, 2316, S136, H13, etc. |

| Mold Base | Self-made, LKM, DME, ASSAB |

| Cavity | Single/multi |

| Runner | Cold runner and hot runner |

| Hot Runner Brand | INCO, HUSKY, YUDO, and others |

| Design Software | UG, AutoCAD, and others |

| Mold Life | 50-500 million shots / 5-6 years, up to 10 years with good maintenance |

| T1 Time | 45-60 days |

| Plastic Material | PP, PC, ABS, PET, PE, PVC, PMMA, TPR, PA6, PA66, ASA, POM, PS, ABS+GF, ABS+PC, POM (Derlin) |

| Gate Type | Pinpoint Gate, Edge Gate, Sub Gate, Film Gate, Valve Gate, Open Gate, etc. |

| Mould Surface Treatment | EDM, texture, high gloss polishing |

| Quality System | ISO9001, SGS, TS16949 |

| HS Code | 8480719090 |

| Origin | Xiamen, China |

| Installation | Fixed |

| Package | Wooden Case |

Mould Quality Control

- Design Verification

– Conduct thorough product analysis and Mouldflow simulations.

– Provide feedback on design issues like thin thickness areas, shrinkage marks, and gate locations.

– Ensure Mould strength, parting lines, and cooling system efficiency meet standards.

- Material Inspection

– Obtain steel quality guarantees and certificates from suppliers.

– Perform rigorous inspections on steel before acceptance to ensure quality.

- Process Control

– Manage key process quality and project progress based on Mould processing documents.

– Provide weekly progress and quality reports to clients.

– Conduct meticulous checks on Mould appearance, cooling systems, and assembly processes.

- Spare Parts Management

– Source qualified spare parts that meet standard models and quality requirements.

– Ensure timely procurement to meet project timelines.

- Assembly Verification

– Follow established procedures for physical processing and inspections.

– Ensure precise alignment of core, cavity, inserts, and other components.

– Thoroughly check fit and functionality of guide pillars, return pins, and cooling systems.

- Final Inspection and Shipment Preparation

– Compile necessary documents including spare parts lists, mold testing videos, and 2D/3D drawings.

– Pack and ship according to customer specifications with emphasis on safety for sea and air shipments.

FAQS:

- Q: Where is your company located?

– A: Our company is situated in Xiamen, Fujian. We operate from our own state-of-the-art facility.

- Q: Do you provide design services?

– A: Certainly! We offer complimentary design services for both product and mold development. Upon placing an order, comprehensive 2D and 3D product designs, as well as mold designs, will be provided to our clients.

- Q: What types of molds can you produce?

– A: We specialize in manufacturing various types of plastic injection molds, with particular expertise in household molds.

- Q: What file formats do you accept?

– A: We accept a wide range of file formats including DXF, DWG, IGS, IGES, STP, PRT, X_T, and PDF.

- Q: What types of steel do you utilize?

– A: Our molds are crafted using steel grades such as P20, P20 (H), 718, 718 (H), 2738, 2738 (H), H13, NAK80, 2344, S136, 4Cr13, S55C, and C45#.

- Q: What materials do you use for testing molds and production?

– A: We employ a variety of materials including PP, PC, PS, PE, HDPE, POM, PA6, PA66, PA6+GF, ABS, TPU, TPE, PVC, SMC, and BMC. Our extensive experience allows us to optimize parameters for achieving flawless products.

- Q: How do you send samples?

– A: Our quotation includes the cost of sample delivery. Samples are shipped twice using reliable courier services such as DHL, UPS, EMS, FedEx, or TNT.