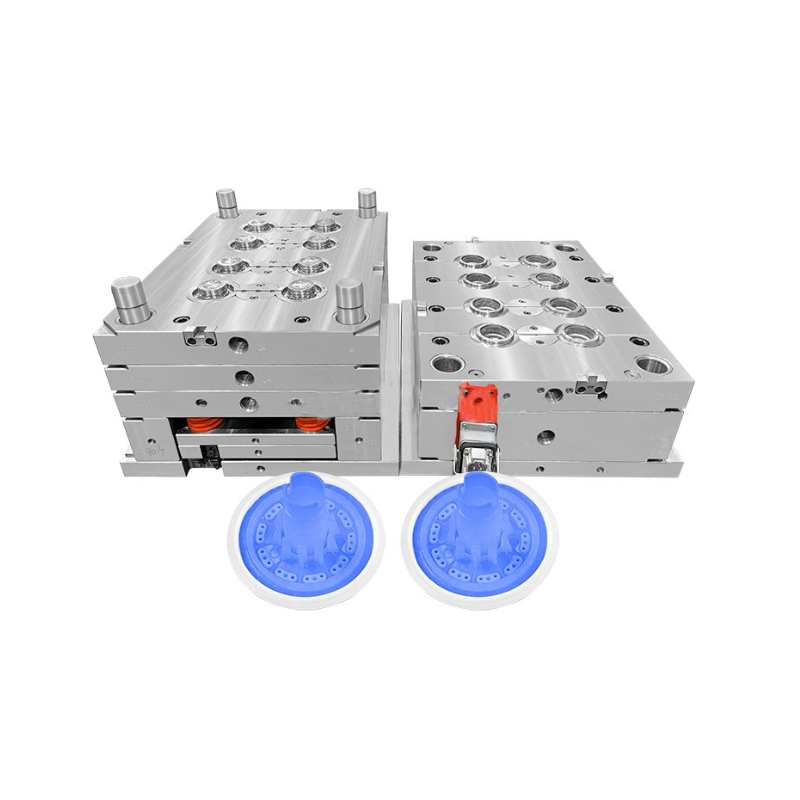

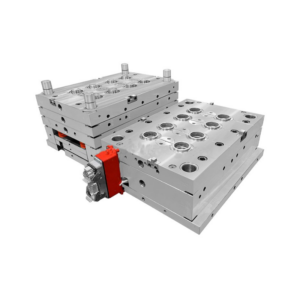

High Quality TPE Rubber Overmould Mold for 2K Injection

Details:

| Detail | Description |

| Place of Origin | Xiamen, China |

| Brand | OEM/ODM |

| Shaping Mode | Plastic Injection Mould |

| Product Material | Steel |

| Plastic Material | PP, PC, PA, PA6, ABS, PET, PVC, POM, etc. |

| Gate System | Cold Runner/Hot Runner |

| Ejection | Pin/Stripper Plate, etc. |

| A.B Plate | 1.1730/P20, etc. |

| Tool Life | Prototype~1,000,000 shots |

| Mold Base | LKM standard mold base + copy HASCO components |

| Cavity & Core | P20/H13/NAK80/S50C/S136/738H, etc. |

| Surface Finish | Polish/Texture/Heat Treatment, etc. |

| Cavities | Single/Multiple/Family mold |

| Lead Time | 3~8 weeks |

Package Details:

Here are the professional packaging details for TPE Rubber Overmould Mold for 2K Injection:

– Packaging Material: Robust wooden crate outfitted with foam inserts.

– Protection: Each individual mold component is meticulously wrapped in protective foam or bubble wrap to prevent any damage during transit.

– Labeling: Clear labeling on the crate includes product name, model number, and detailed handling instructions for easy identification and proper handling.

– Inner Cushioning: Foam inserts are strategically placed to provide ample cushioning and separation between components, minimizing friction and potential damage.

– Sealing: The crate is securely sealed using high-strength adhesive tape, ensuring the contents remain intact and protected throughout transportation.

– Purpose: This packaging is selected to ensure the utmost protection for delicate mold components against scratches, impacts, and other hazards during transit. It guarantees that the components arrive at their destination in pristine condition, ready for immediate use in production.

Manufacturing Workflow for Mold Production:

- Product Design and Analysis

– Conceptualization and creation of product models and drawings.

– Conceptualization and creation of product models and drawings.

– Feasibility analysis of product design.

- Mold Structure Design

– Development of mold structure schematics using CAD software.

– Iterative design process considering factors like shrinkage, draft angles, and structure optimization.

- Data Management

– Archiving historical data and instance citations for reference.

– Management of existing facility data.

- Structural Analysis

– Computer-assisted analysis of mold structures using CAE software.

– Evaluation of key components such as core, cavity, and electrodes.

- Mold Ordering

– Ordering of mold materials and components based on finalized assembly drawings.

- Process Planning and Execution

– Establishment of process techniques and parameters (CAPP).

– Establishment of process techniques and parameters (CAPP).

– Creation of numerical control programs (CAM).

– Quality evaluation through simulation before production.

- Machining and Sampling

– CNC machining of molds.

– Sample testing and confirmation of quality.

- Production Management

– Business assistance in order completion and finishing.

– Production planning and scheduling.

– Shift management including night shifts.

- Quality Control

– In-process quality control (IPQC) during production.

– Final customer inspection before shipment.

- Warehousing

– Storage of finished goods in the warehouse.

This structured workflow ensures systematic handling of tasks from product design to production, maintaining quality and efficiency throughout the manufacturing process.

We offer comprehensive solutions for custom plastic products:

– Mold design and precision molding

– High-quality plastic injection molding services

– Assembly, Pad Printing, Silk Screen Printing, Painting, Ultrasonic Welding, and Packaging

Our services cover all aspects of plastic product customization under one roof.