High Standard Compression Molding Rubber Mold Services

Basic Information:

| Certification | RoHs, FDA, REACH |

| Mould Life | 500,000 – 1,000,000 times |

| Warranty | 5 Years |

| Customized | Customized |

| After-sales Service | Maintenance |

| Steel | 45#, 50#, P20, S136, 718, etc. |

| Processing Standard | Precision |

| Ejection Mold | Auto |

| Transport Package | Wooden Boxes |

| Specification | SGS, RoHs, CE |

| Trademark | OEM |

| Origin | Xiamen, China |

| Production Capacity | 80 Sets Mold/Month |

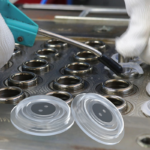

Rubber molds undergo diverse machining processes to attain specific shapes, facilitating the molding of various silicone rubber components. These components include O-rings, gaskets, seals, bushings, sleeves, grommets, and more.

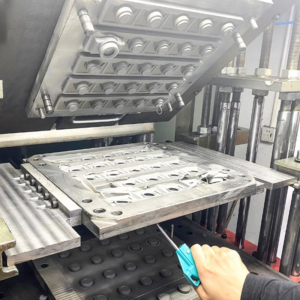

Structure of Rubber Compression Molds:

Silicone compression molds featuring a dynamic core mechanism

(Ejection system: Facilitates safe product removal from the mold, minimizing the risk of product damage or injury during extraction)

Rubber Compression Mold with Mold Inserts:

(Primarily utilized for products with intricate hollow designs)

Silicone Compression Mold Types:

- Two-Plate Compression Mold

- Three-Plate Compression Mold

- Rubber Transfer Injection Mold

Request for Rubber Mould Quotation:

- Provide 2D/3D design drawings, samples, or essential project details.

- Specify material requirements: Rubber ID (Rubber, Solid Silicone/LSR).

- Indicate mold cover/base steel requirements or expected mold shot life.

- Detail surface finish preferences.

- Specify size tolerance requirements: +/-0.005mm to +/-0.3mm.

At our company, we are committed to delivering holistic solutions and services that cover the entire production lifecycle. From initial product design analysis, through mold design and fabrication, to prototyping, mass production, and final product assembly, we provide comprehensive support at every stage. Our product range caters to diverse industries including electronics, medical devices, automotive, and machinery components, among others.