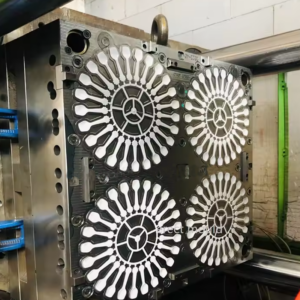

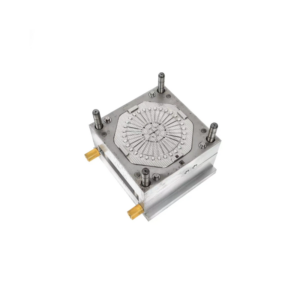

Hot Selling ISO9001 Injection Molding for Kitchen Ware Plastic Spoon

Characteristics:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand | OEM/ODM |

| Product Material | Plastic |

| Product | Household Product |

| Name | Spoon Mold |

| Mould Material | P20, 718HH, 2738, H13, 45#, C50, etc |

| Mould Base | LKM, HASCO, etc |

| Cavity | Single/Multi |

| Runner | Cold/Hot |

| Mould Life | 300,000 – 500,000 shots |

| Design Software | UG, Proe, CAD/CAM, etc |

| Delivery Time | 45-60 days |

| Package | Wooden Case |

| Advantage | Reasonable price, high quality, on-time delivery |

| Selling Units | Single item |

| Single Package Size | 200 x 150 x 200 cm |

| Single Gross Weight | 1000.000 kg |

Our Competitive Edge:

– Premium Quality Standards

– Competitive Pricing Structure

– Timely Delivery Commitment

– Exceptional Post-Sale Support

– Stringent Quality Assurance

– Automation Implemented Across All Moulds

Surface Treatments for Kitchenware Plastic Spoons

- Polishing

Polishing is done to achieve a smooth and glossy surface finish, enhancing the appearance and feel of the plastic spoon.

- Texturing

Texturing adds patterns or textures to the surface of the spoon, improving grip and aesthetics.

- Painting

Painting allows for customization of colors and designs on the spoon’s surface, providing branding or decorative options.

- Coating

Coating the surface provides additional protection, durability, and resistance to scratches or wear.

- Printing

Printing methods can add logos, patterns, or instructions onto the spoon’s surface, offering branding opportunities or functional information.

Mould Manufacturing Process

– Inquiry Reception

– Receive customer inquiries promptly.

– Quotation and Details

– Provide price offers or detailed information within 16 hours.

– Drawing Submission

– Customers provide 2D/3D drawings and additional mold details.

– Order Confirmation

– Confirm order details including quality, price, material, delivery time, payment terms, etc.

– Production Preparation

– Prepare for production according to client’s requirements.

– Mold Detail Confirmation

– Clients confirm the specific details of the mold.

– Surface Shaping

– Perform operations such as drilling holes, high-speed carving, wire cutting, EDM, etc.

– Sample Testing

– Arrange for test mold production and send samples to customers for evaluation.

– Feedback and Adjustments

– If clients are not satisfied with the samples, provide feedback for adjustments.

– Repair and Finishing

– Conduct repairs, polishing, and texture application as necessary.

– Sample Approval

– Send revised samples until customers’ confirmation is obtained.

– Delivery

– Arrange delivery by sea, air, etc., as per customer preference.

Customer Service Standards:

Pre-sale:

– Thorough Confirmation:Discuss and confirm product types and quantities with customers to ensure accuracy.

– Attentive Attention:Approach each inquiry with patience, seriousness, and attention to detail.

– Lead Time Management:Efficiently arrange production and closely monitor lead times to meet customer expectations.

– Careful Inspection:Conduct thorough inspections before delivery to ensure accuracy and quality.

After-sales:

– Prompt Delivery:Arrange delivery promptly after order confirmation.

– Delivery Confirmation:Confirm receipt of items by customers upon delivery.

– Feedback Collection:Gather feedback from customers and strive to provide the best possible service.