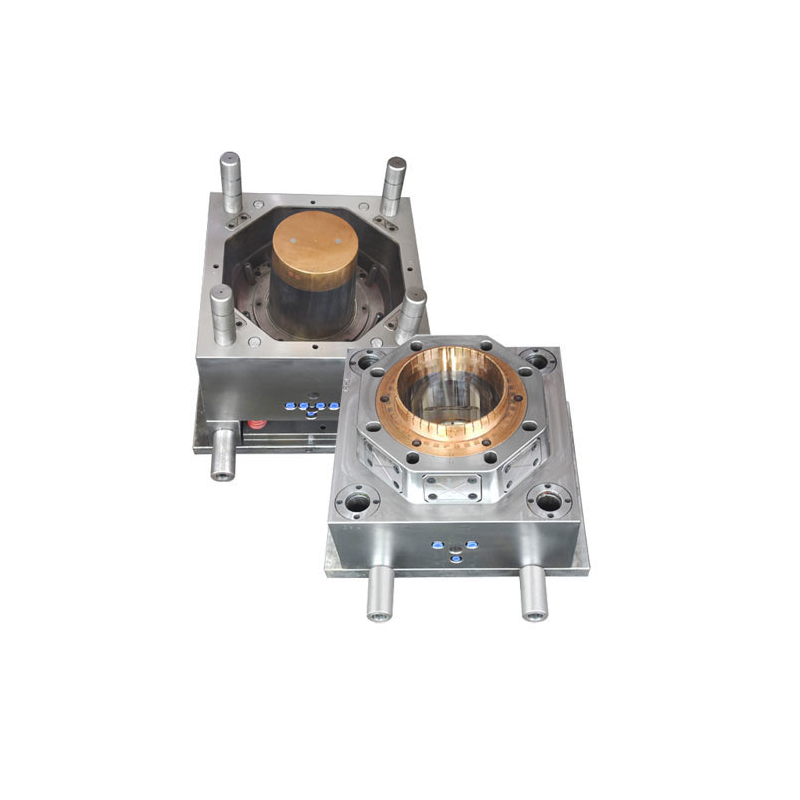

Industrial bucket mould tools are specialized equipment used in the manufacturing of plastic buckets through injection molding or blow molding processes. These molds are designed with precision to create buckets of various sizes, shapes, and features, ensuring consistent quality and durability in the final product. Made from high-strength materials, industrial bucket mould tools are built to withstand the high pressure and temperatures involved in the molding process. They are used across various industries, including packaging, construction, and agriculture, to produce large quantities of functional and robust plastic buckets for diverse applications.

Basic Information

Mold Type: Plastic Injection Mold

Mold Material Options:P20, 718, 738, NAK80, S136

Mold Base Standards: HASCO, DME, MISUMI, JIS, LKM, etc.

Mold Runner System:Cold Runner / Hot Runner

Mold Gate Options:Slide Gate, Sub Gate, Pin-point Gate

Cavity:Single or Multi-Cavity

Design Software Supported:UG, PROE, CAD, SOLIDWORKS

Molding Equipment Used:CNC, Wire Cutting, Milling Machine, EDM

Compatible Raw Materials:ABS, PP, PC, PA6, PA66, PVC, POM, PMMA, PS, etc.

Packaging Method:Wooden pallet or carton

OEM Services:Available—please provide 2D/3D files or samples

Lead Time:Approximately 30 days

Advantages of Our Mould:

-

Superior Quality:

– Our molds are manufactured using high-grade materials and state-of-the-art techniques, ensuring exceptional durability, precision, and longevity. Each mold undergoes rigorous quality control checks to meet stringent industry standards.

-

Customization:

– We offer highly customizable mold designs tailored to meet specific client requirements. Our team works closely with clients to develop molds that align perfectly with their unique production needs and specifications.

-

Advanced Technology:

– Utilizing the latest in CNC machining, laser cutting, and precision engineering, our molds are crafted with unparalleled accuracy. Our advanced technology ensures consistent, high-quality output and reduces production downtime.

-

Rapid Prototyping:

– We provide quick turnaround times for prototypes, allowing clients to test and validate their designs swiftly. This accelerates the product development process and brings products to market faster.

-

Cost-Effective Solutions:

– By optimizing our production processes and utilizing efficient manufacturing techniques, we offer cost-effective mold solutions without compromising on quality. Our competitive pricing ensures value for money for our clients.

-

Eco-Friendly Materials:

– We prioritize the use of eco-friendly materials and sustainable manufacturing practices. Our commitment to environmental responsibility ensures that our molds have a minimal impact on the environment.

Factory Show

Our 4,500㎡ factory boasts over 20 years of OEM expertise and is equipped with world-class machinery, including Roders, Makino, Sodick, and YCM. Leveraging advanced tooling technology, we achieve micron-level precision in tool manufacturing. With ARBURG, Miltitech, and 2KM equipment, we produce ultra-precision components as small as 0.02g and as thin as 0.1mm. Our ISO-certified Class 8 medical-grade dust-free workshop ensures a controlled environment for high-quality medical device components.