Mould Manufacturing Process

– Inquiry Reception

– Receive customer inquiries promptly.

– Quotation and Details

– Provide price offers or detailed information within 16 hours.

– Drawing Submission

– Customers provide 2D/3D drawings and additional mold details.

– Order Confirmation

– Confirm order details including quality, price, material, delivery time, payment terms, etc.

– Production Preparation

– Prepare for production according to client’s requirements.

– Mold Detail Confirmation

– Clients confirm the specific details of the mold.

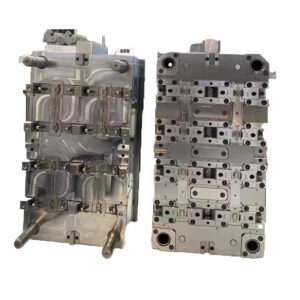

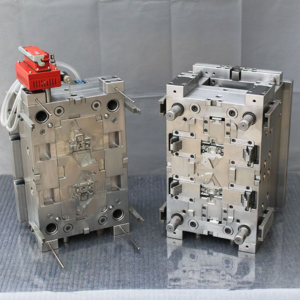

– Surface Shaping

– Perform operations such as drilling holes, high-speed carving, wire cutting, EDM, etc.

– Sample Testing

– Arrange for test mold production and send samples to customers for evaluation.

– Feedback and Adjustments

– If clients are not satisfied with the samples, provide feedback for adjustments.

– Repair and Finishing

– Conduct repairs, polishing, and texture application as necessary.

– Sample Approval

– Send revised samples until customers’ confirmation is obtained.

– Delivery

– Arrange delivery by sea, air, etc., as per customer preference.

Factory Show:

We operate with advanced machinery and equipment to ensure top-notch quality. Our facilities feature CNC machines, Mirror EDM, EDM, and Slow-Speed Wire Cut WC for precise mold-making. Production is supported by 15 rubber compression molding machines, 2 LSR injection machines, and quality control tools such as 3D projectors and durometers. Our setup also includes an AutoDryer Line, automatic screen printing, high-speed doming machines, and CNC machines. This combination of cutting-edge technology and rigorous quality control ensures we deliver products of the highest standard.

and Slow-Speed Wire Cut WC for precise mold-making. Production is supported by 15 rubber compression molding machines, 2 LSR injection machines, and quality control tools such as 3D projectors and durometers. Our setup also includes an AutoDryer Line, automatic screen printing, high-speed doming machines, and CNC machines. This combination of cutting-edge technology and rigorous quality control ensures we deliver products of the highest standard.

Comprehensive Services:

We offer a complete solution from initial concept to finished product, transforming paper sketches into functional parts.

- Versatile molds for various plastic products

- Rapid prototyping capabilities

- Secure and expedited delivery

- High-quality products at competitive prices

- OEM support

- Exceptional service quality

- Welcoming custom designs and meeting customer specifications

- Extensive experience in mold production and design with a rigorous management system

- Outstanding after-sales support